Color-difference-eliminating light-emitting chip grading method and application method of graded light-emitting chips

A light-emitting chip and binning technology, which is applied in the direction of electrical components, circuits, semiconductor/solid-state device testing/measurement, etc., can solve problems such as differences, increased maintenance costs, and color distortion of the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Red, green, and blue are all displays made of light-emitting chips within one gear (that is, within the same CIE 1931 color coordinate range). The gear division principle is determined by theoretical calculation combined with the actual human eye evaluation effect. This embodiment gear range is selected as: R(δx)=0.0035, R(δy)=0.0025; G(δx)=0.0060, G(δy)=0.0130; B(δx)=0.0025, B(δy)= 0.0020, the designated gear can be appropriately reduced according to the accuracy of the manufacturer's equipment, not limited to the above description. For example: R(δx)=0.0030, R(δy)=0.0020; G(δx)=0.0040, G(δy)=0.0100; B(δx)=0.0020, B(δy)0.0020

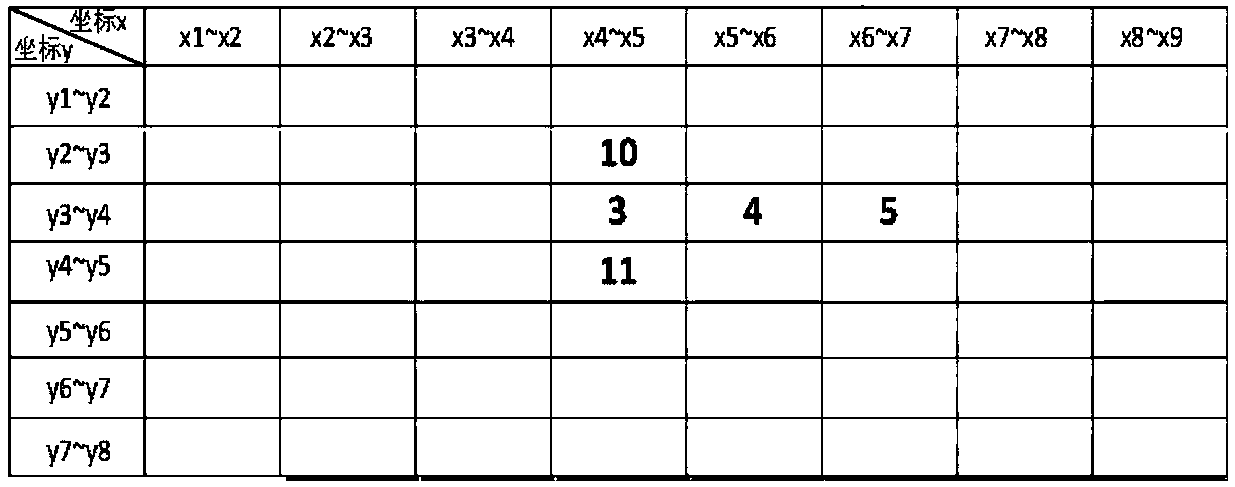

[0041] Manufacturers of green light, blue light, and red light-emitting chips test and classify light-emitting chips according to the stalls shown in Table 2, Table 3, and Table 4 respectively. The test data of a single light-emitting chip in Table 2 falls in which box in the table, which gear it belongs to. When the array module is in the so...

Embodiment 2

[0043] Red and green use light-emitting chips in one gear (that is, within the same CIE 1931 color coordinate range), and blue uses a display made of multiple light-emitting chips in adjacent gears. This embodiment gear range is selected as: R(δx)=0.0030, R(δy)=0.0020; G(δx)=0.0040, G(δy)=0.0100; B(δx)=0.0020, B(δy)= 0.0015

[0044] Manufacturers of green, blue, and red light-emitting chips test and classify light-emitting chips according to the gears shown in Table 2, Table 3, and Table 4. The test data of a single light-emitting chip falls in which box in the table, which gear it belongs to. During the crystal bonding operation, red and green select a light-emitting chip in a box, and blue selects n (1<n<<8) chips in a horizontal or vertical continuous box. For example: all the green light-emitting chips are selected from the 3rd gear in Table 1, all the red are from the 17th gear in Table 3, and all the blue are from the 13, 12, 7 three consecutive gears in the y directio...

Embodiment 3

[0046] Red and blue use one gear light-emitting chip (that is, within the same CIE 1931 color coordinate range), and green uses a display made of multiple adjacent gear light-emitting chips. This embodiment gear range is selected as: R(δx)=0.0035, R(δy)=0.0025; G(δx)=0.0060, G(δy)=0.0130; B(δx)=0.0025, B(δy)= 0.0020.

[0047] Manufacturers of green, blue, and red light-emitting chips test and classify light-emitting chips according to the gears shown in Table 2, Table 3, and Table 4. The test data of a single light-emitting chip falls in which box in the table, which gear it belongs to. During the crystal bonding operation, red and blue select a light-emitting chip in a box, and green selects n (1<n<<4) light-emitting chips in a horizontal or vertical continuous box. For example: all the light-emitting chips in the 7th position in Table 2 are selected for blue, the luminous chips in the 14th position in Table 3 are used for red, and the light-emitting chips in three consecut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com