Wetting-drying cycle testing device for soil three-directional soaking under action of load

A dry-wet cycle and test device technology, applied in soil material testing, measuring devices, using stable tension/pressure to test the strength of materials, etc. Avoid disturbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

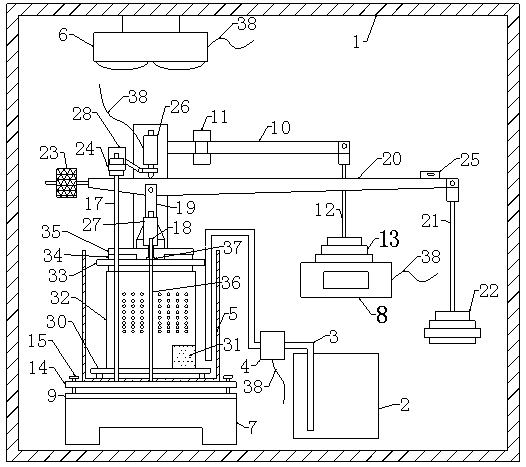

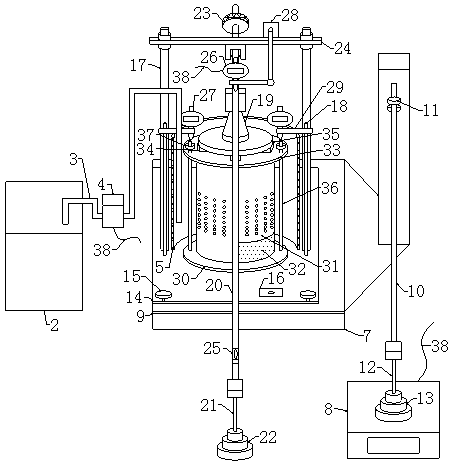

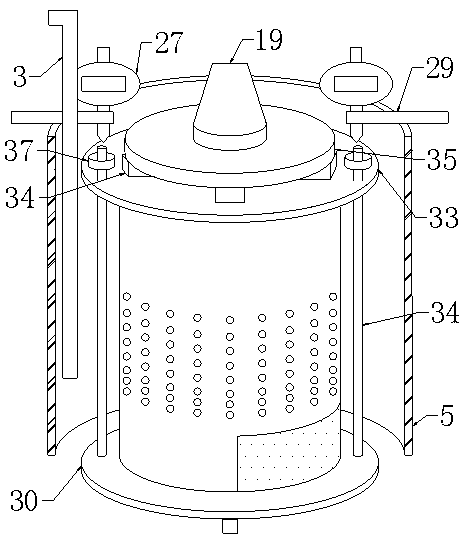

[0030] Embodiment of the present invention: a dry-wet cycle test device for three-way water immersion of soil under load, as attached Figure 1-8 As shown, it includes eight parts including test chamber 1, humidification mechanism, drying mechanism, weighing mechanism, pressurizing mechanism, measuring mechanism, test cylinder mechanism, and rebound prevention mechanism.

[0031] The frame of the test box 1 is made of steel, and the periphery is closed by glass, so that the change of the sample and the instrument reading during the dry-wet cycle can be clearly observed in real time.

[0032] The humidifying mechanism is composed of a water storage tank 2, a water pipe 3, a water pump 4 and a soaking tank 5. The function of the water storage tank 2 is to supply water during humidification and receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com