Blade mortise adhesive tape repair device and method

A blade tenon and repair method technology, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve problems such as inability to repair, achieve the effects of shortening the production cycle, avoiding false contact, and ensuring the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

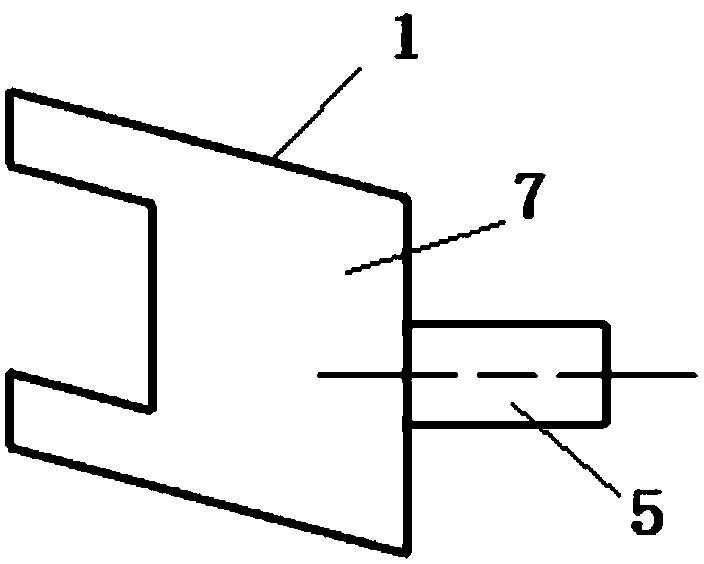

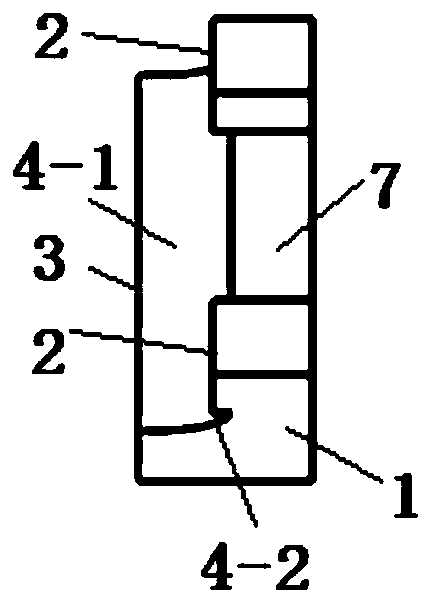

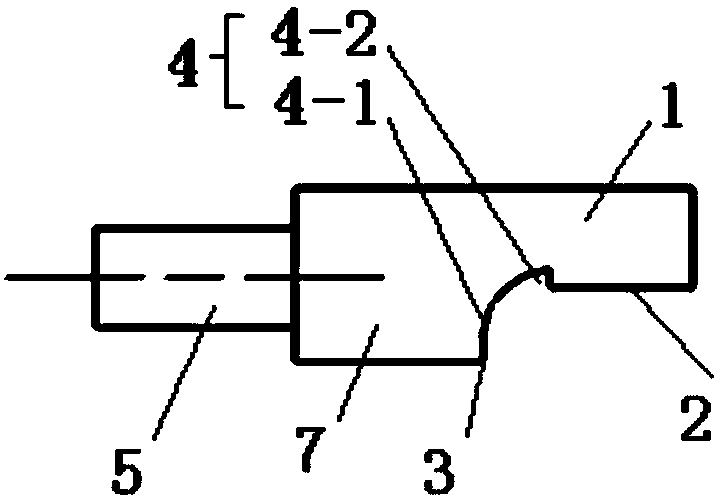

[0027] Such as image 3 shown, refer to figure 1 , figure 2 and Figure 4 , the device for repairing the tenon rubber strip of the blade of the present invention includes a repair block 7, and the repair block 7 is provided with a first positioning surface 1 for fitting and positioning with the end face locking block 6-1 of the tenon 6, and is used for aligning with the bottom surface of the tenon 6 6-4 The second positioning surface 2 for fitting and positioning, and the mold part 4 for repairing the gradient rubber strip part 6-5 rubber strip matching the gradient rubber strip part 6-5 of the tenon 6, the mold part 4. A separation space 4-2 is provided near the second positioning surface 2 for separating from the glue strip on the bottom surface 6-4 of the tenon 6.

[0028] refer to Figure 2 ~ Figure 4 , as a preferred embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com