Regenerative cycle type ORC (organic Rankine cycle) power generation system utilizing LNG (liquid nature gas) cold energy and industrial waste heat

An industrial waste heat and power generation system technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve problems such as the complex structure of the secondary ORC cycle, without considering thermal stress, etc., to improve energy utilization, reduce thermal pollution, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in combination with preferred embodiments and accompanying drawings.

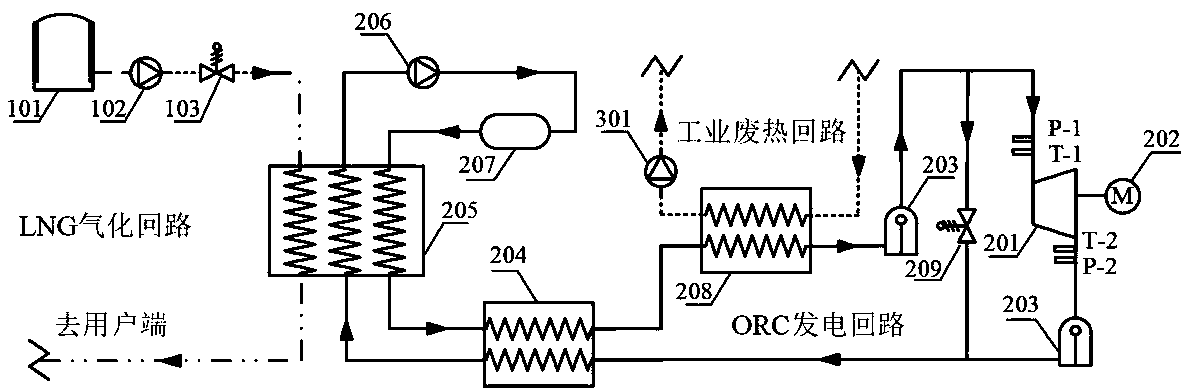

[0024] Such as figure 1 As shown, an ORC power generation system utilizing LNG cold energy and industrial waste heat with a heat recovery cycle, the system includes an LNG gasification circuit, an ORC power generation circuit and an industrial waste heat circuit; wherein, the cold source of the ORC power generation circuit is composed of The cold energy released by the LNG gasification circuit is provided, and the heat source of the ORC power generation circuit is provided by the industrial waste heat circuit.

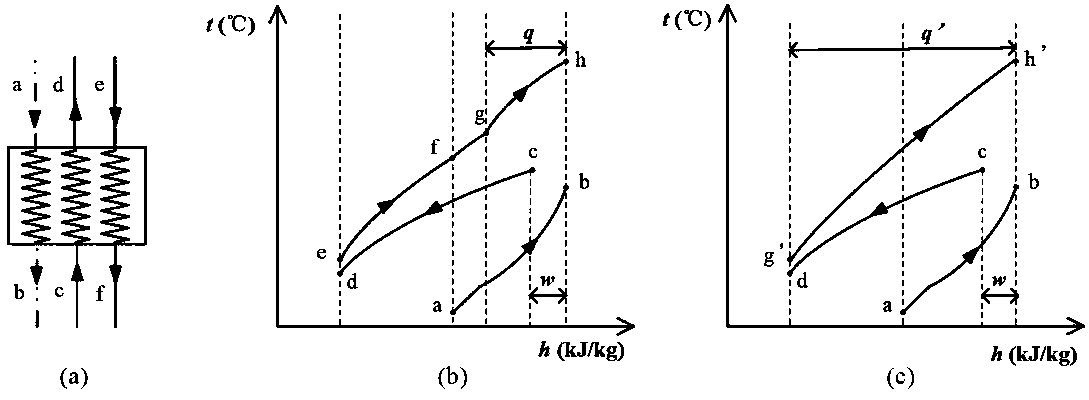

[0025] As a preferred embodiment of the present invention, the LNG gasification circuit includes an LNG liquid storage tank 101, an LNG circulation pump 102, an LNG flow regulating valve 103 and a three-fluid heat exchanger 205 connected in sequence; the LNG gasification circuit Exchange heat with the ORC power g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com