A kind of mg-al-ca-ce series magnesium alloy and preparation method thereof

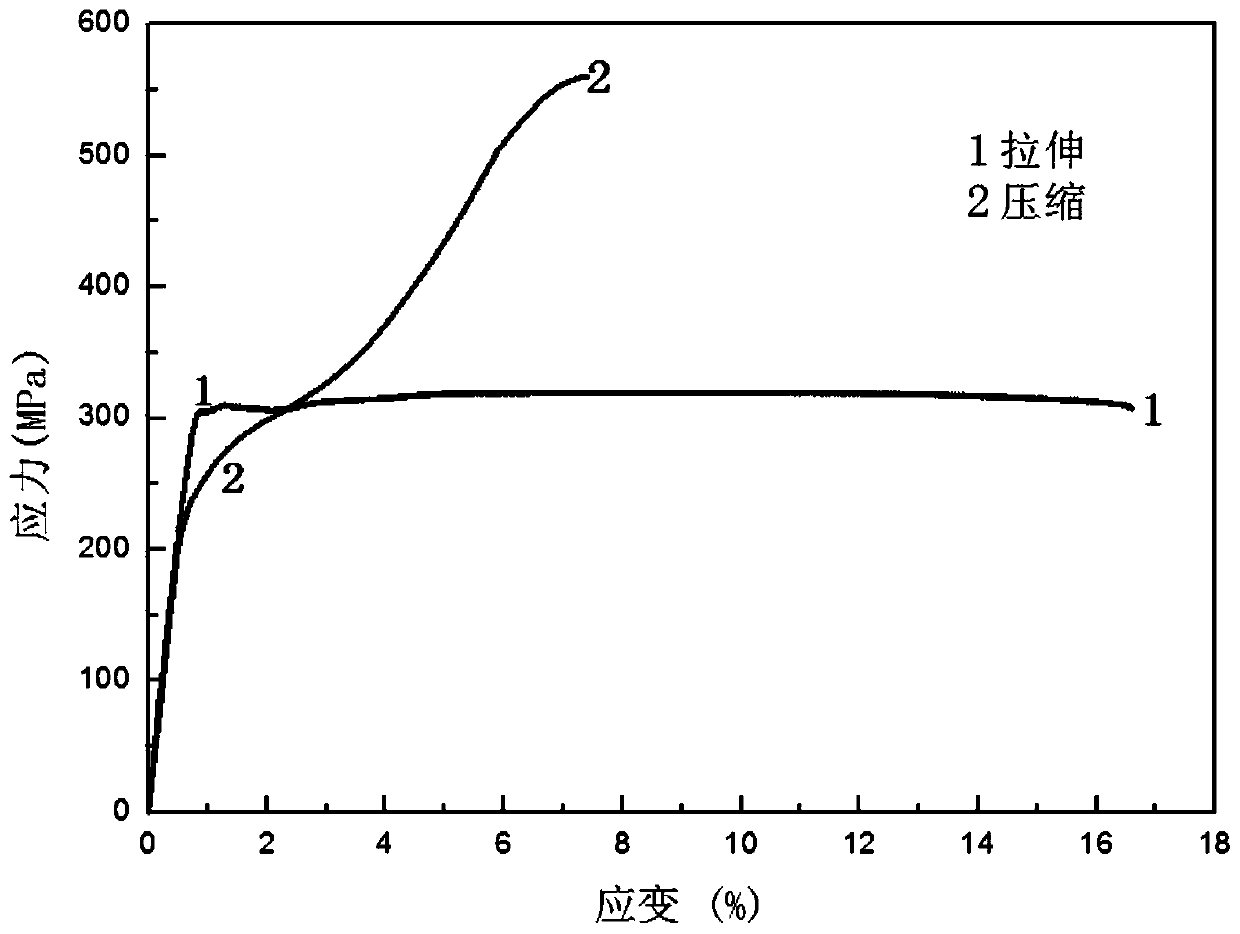

A mg-al-ca-ce, magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of low absolute strength and yield ratio, low alloy tension-compression symmetry, increase alloy cost, etc., and achieve excellent extrusion deformation performance. , the effect of high tension and compression symmetry, increasing the cost of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The composition (mass percentage) of the Mg-Al-Ca-Ce series magnesium alloy is: Al is 4.0%, Ca is 3.5%, Ce is 0.5%, and the rest is magnesium and unavoidable impurities.

[0039] The preparation method of above-mentioned Mg-Al-Ca-Ce series magnesium alloy:

[0040] (1) Alloy smelting and casting: First, weigh industrial pure Mg, industrial pure Al, Mg-Ca, and Mg-Ce master alloys according to the composition requirements, put them into a resistance furnace, and preheat at 150°C for 30 minutes ; 2 and SF 6 Heat pure Mg in a resistance furnace protected by mixed gas, keep it warm at 680°C to melt the pure Mg, then add the preheated pure Al, Mg-Ca, Mg-Ce master alloy, heat it up to 700°C and keep it for 30 minutes, wait for The alloying elements are completely melted, stirred evenly, and the surface scum is removed, and the temperature is lowered to 690-700°C after standing for 20 minutes. 2 and SF 6 Cast into ingots under the protection of mixed gas; CO 2 and SF 6 In...

Embodiment 2

[0044] The composition (mass percentage) of the Mg-Al-Ca-Ce series magnesium alloy is: Al is 4.5%, Ca is 3.0%, Ce is 1.0%, and the rest is magnesium and unavoidable impurities.

[0045] The preparation method of above-mentioned Mg-Al-Ca-Ce series magnesium alloy:

[0046] (1) Alloy smelting and casting: First, weigh industrial pure Mg, industrial pure Al, Mg-Ca, and Mg-Ce master alloys according to the composition requirements, put them into a resistance furnace, and preheat at 150°C for 30 minutes ; 2 and SF 6 Heat pure Mg in a resistance furnace protected by mixed gas, keep it warm at 700°C to melt the pure Mg, then add the preheated pure Al, Mg-Ca, Mg-Ce master alloy, raise the temperature to 720°C and keep it for 25 minutes, wait The alloying elements are completely melted, stirred evenly, and the surface scum is removed, and the temperature is lowered to 690-700°C after standing for 20 minutes. 2 and SF 6 Cast into ingots under the protection of mixed gas; CO 2 and S...

Embodiment 3

[0050] The composition (percentage by mass) of the Mg-Al-Ca-Ce series magnesium alloy is: Al is 5.0%, Ca is 2.5%, Ce is 0.5%, and the rest is magnesium and unavoidable impurities.

[0051] The preparation method of above-mentioned Mg-Al-Ca-Ce series magnesium alloy:

[0052] (1) Alloy smelting and casting: First, weigh industrial pure Mg, industrial pure Al, Mg-Ca, and Mg-Ce master alloys according to the composition requirements, put them into a resistance furnace, and preheat at 150°C for 30 minutes ; 2 and SF 6 Heat pure Mg in a resistance furnace protected by mixed gas, keep it at 730°C to melt the pure Mg, then add the preheated pure Al, Mg-Ca, Mg-Ce master alloy, heat it up to 750°C and keep it for 30 minutes, wait The alloying elements are completely melted, stirred evenly, and the surface scum is removed, and the temperature is lowered to 690-700°C after standing for 20 minutes. 2 and SF 6 Cast into ingots under the protection of mixed gas; CO 2 and SF 6 In the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com