Tower crane safety monitoring system and method

A safety monitoring system and safety monitoring technology, applied in safety devices, clockwork mechanisms, hoisting devices, etc., can solve the problems of low level of intelligence, shortened service life of steel wire ropes, and prone to negligence, etc., and achieve high intelligence and high efficiency. Improve the life of tower crane, improve the effect of intelligence and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

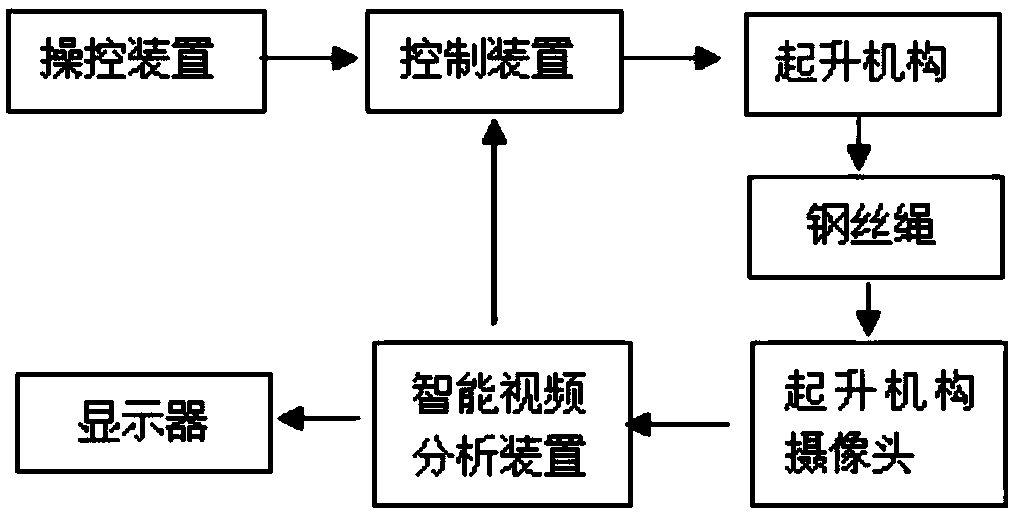

[0022] Such as figure 1 Shown is a tower crane safety monitoring system, including a control device, a control device, a hoisting mechanism camera 2, a hoisting mechanism 1, a steel wire rope, an intelligent video analysis device, and a display;

[0023] The control device is used to give a control signal for the operation of the tower crane;

[0024] The control device is the core of the monitoring system, and is used to receive the operation action control signal of the tower crane from the control device and issue an operation action control command;

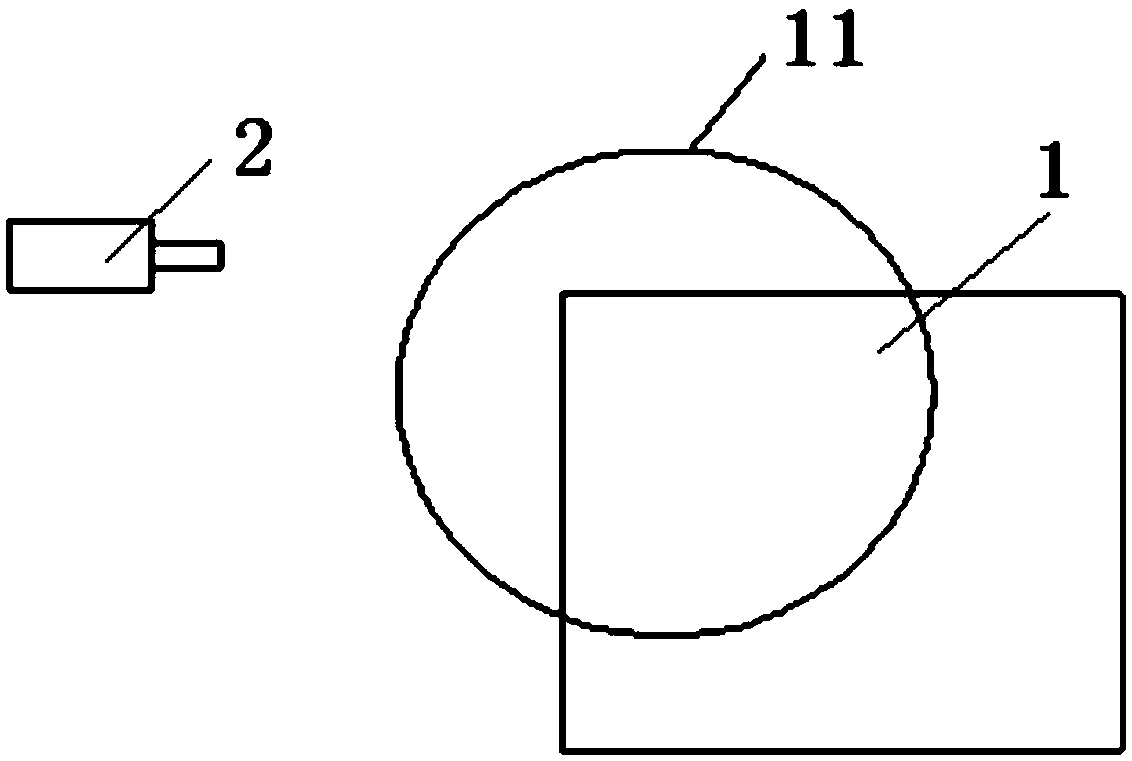

[0025] The hoisting mechanism camera is used for video monitoring the wire rope on the hoisting mechanism reel;

[0026] The intelligent video analysis device is used for the collection, compression, intelligent analysis and storage of the video or pictures of the lifting mechanism camera;

[0027] The display is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com