Plastic injection mold

An injection mold and plastic technology, which is applied in the field of plastic injection molds, can solve the problems of adjusting the discharge speed and complex structure, and achieve the effect of precise injection molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

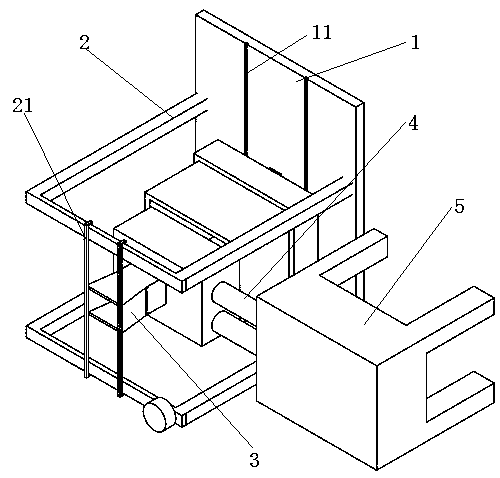

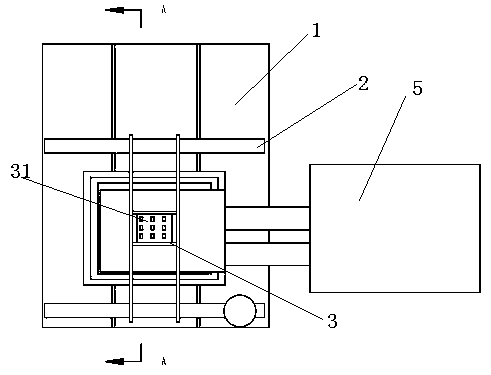

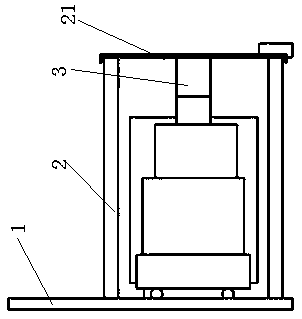

[0020] Such as Figure 1-6 As shown, a plastic injection mold includes a base plate 1, a bracket 2, an injection molding mechanism 4 and a receiving bin 5, the bracket 2 is installed on the base plate 1, the bottom of the injection molding mechanism 4 is provided with rollers, and the top of the bracket 2 is provided with two parallel The guide rail 21, the bottom plate 1 is provided with a guide groove 11 at the corresponding position of the roller, the left side of the injection molding mechanism is provided with a receiving bin 5, and the receiving bin 5 is used to collect the injection molded plastic parts, and the top of the injection molding mechanism 4 is provided with a feeding hopper 3, The upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com