A device for tightening nuts

A nut and nut sleeve technology, applied in screwdrivers, program control manipulators, wrenches, etc., can solve the problems of long time for tooling preparation, low success rate, and long time to tighten large nuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

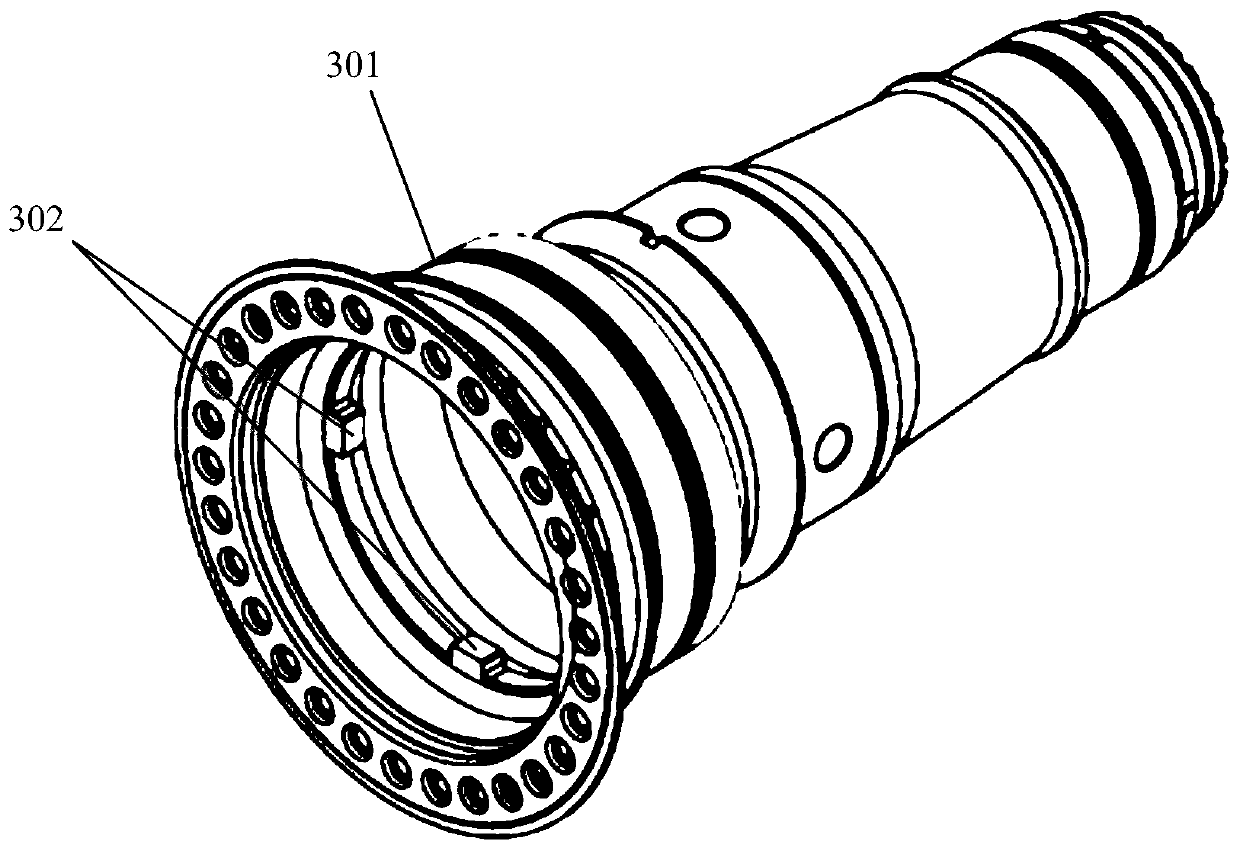

[0044] The invention provides a nut tightening device, which can automatically connect a nut sleeve with a nut and further screw the nut.

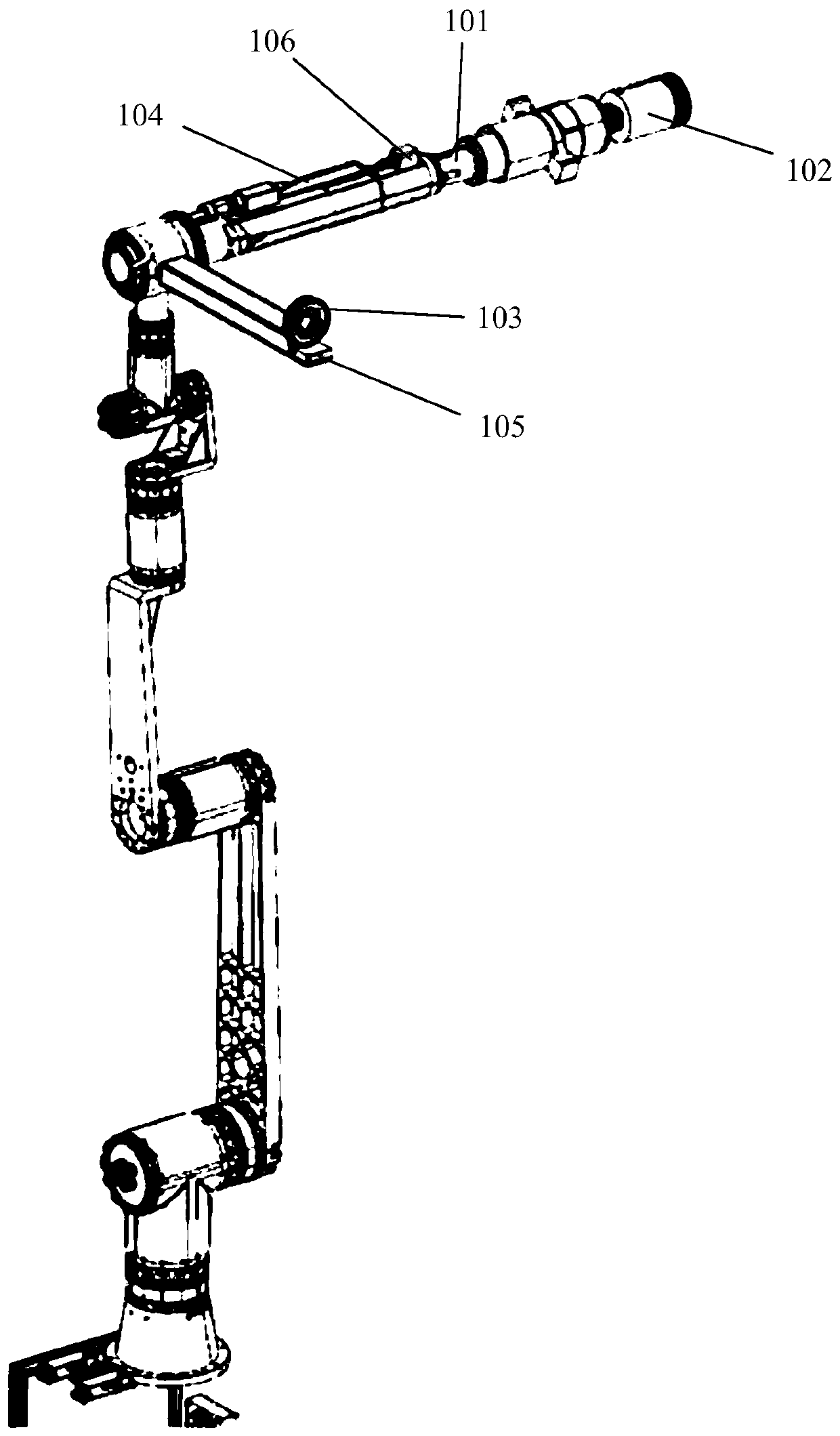

[0045] Please see figure 1 , figure 1 A schematic structural view showing an aspect of a device for tightening nuts according to the present invention.

[0046] The device includes a positioning rod 101 that can be positioned at any position in the space, and a nut sleeve 102 is provided at the end of the positioning rod 101, and the nut sleeve 102 can just cover the nut that needs to be tightened.

[0047] Since the nut may be at any position in the space, the positioning rod 101 that can be positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com