A fully automatic assembly line for oil pump accessories

An assembly line, fully automatic technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low assembly efficiency, high spring difficulty, and spring compression not reaching the preset value, so as to reduce labor intensity, Improve the assembly accuracy and eliminate the effect of uneven compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

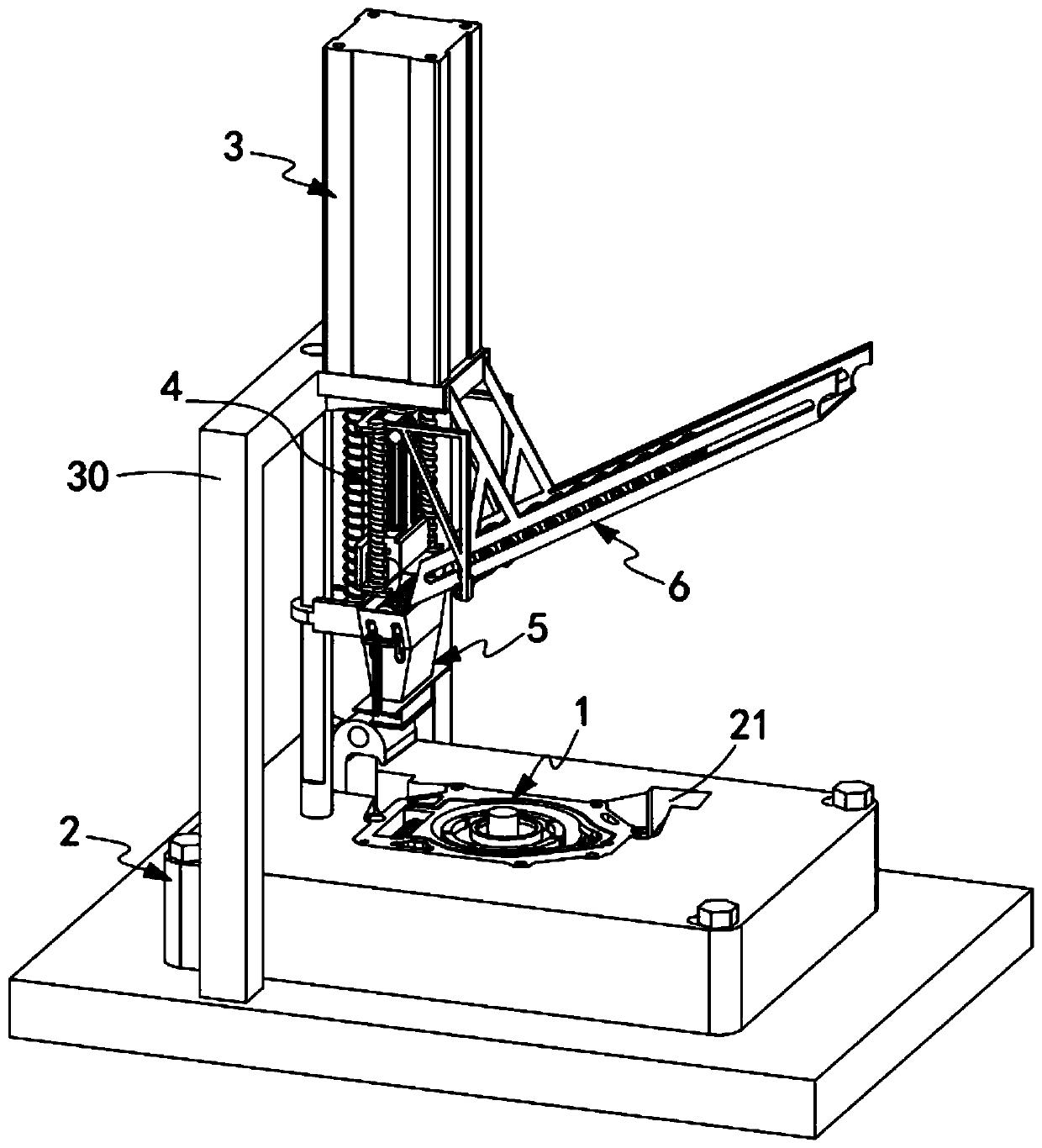

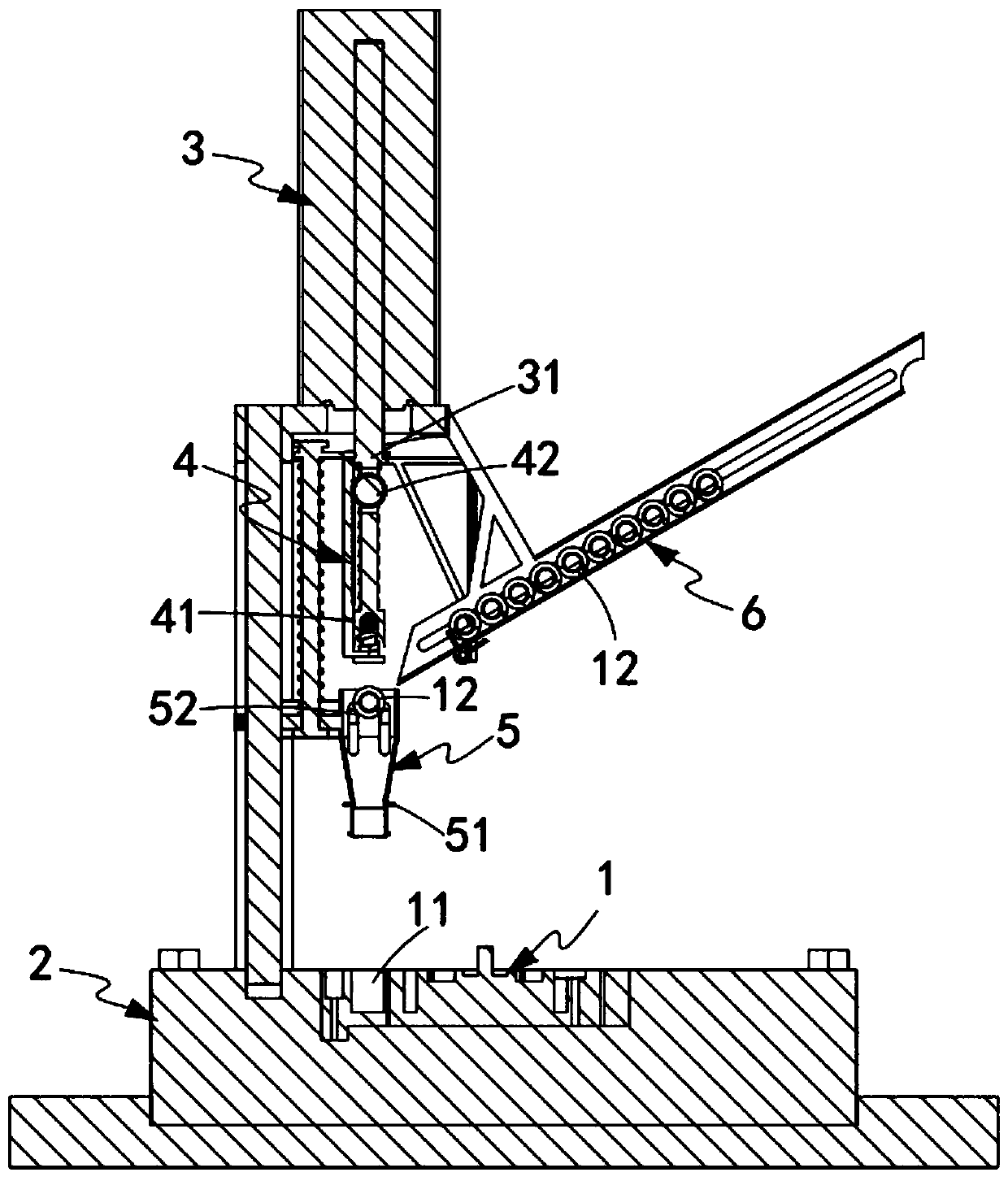

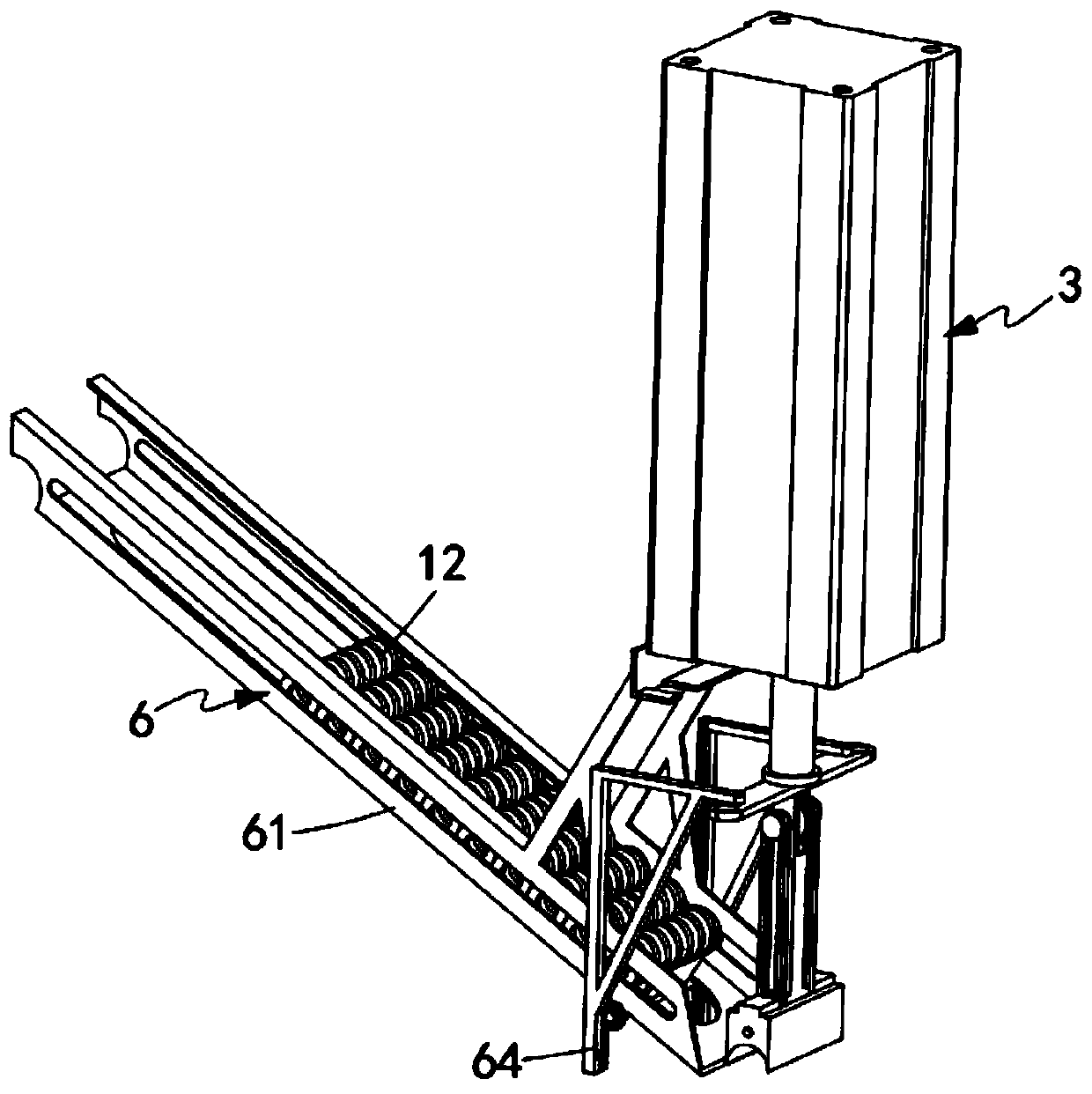

[0077] Such as figure 1 , figure 2 , Figure 4 and Figure 11 As shown, a fully automatic assembly line for oil pump accessories, which includes a pump body 1, a spring installation groove 11 is arranged on the pump body 1, and the spring installation groove 11 is used for installing a spring 12, and also includes:

[0078] Mounting seat 2, the mounting seat 2 is provided with a placing groove 21 that is shaped like the pump body 1, the pump body 1 is placed in the placing groove 21, and the spring mounting groove 11 is exposed horizontally;

[0079] Push the cylinder 3, the push cylinder 3 is installed above the mounting seat 2 through the gantry frame 30, and the push end 31 of the push cylinder 3 is vertically pushed downwards vertically to the spring installation groove 11;

[0080] Spring pushing mechanism 4, described spring pushing mechanism 4 is arranged on the pushing end 31 of described pushing cylinder 3, and it pushes described spring 12 by described pushing cy...

Embodiment 2

[0113] Figure 17 It is a structural schematic diagram of Embodiment 2 of a fully automatic assembly line for oil pump accessories of the present invention; Figure 17 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0114] Such as Figure 17 As shown, a fully automatic assembly line for oil pump accessories, the spring pushing mechanism 4 also includes a rotating assembly 42 driven to rotate by the pushing cylinder 3, when the pushing block 41 pushes the spring 12, the rotating assembly 42 The springs 12 are driven to rotate synchronously.

[0115] Such as Figure 18 , Figure 19 and Figure 20 As shown, wherein, the rotating assembly 42 includes:

[0116] Rotating roller 43, said rotating roller 43 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com