Horizontal type double-cone spiral sedimentation centrifuge

A technology of spiral sedimentation and centrifuge, which is applied in the direction of centrifuge and centrifuge with rotating drum, etc., which can solve the problems of poor effect and low efficiency of suspension separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the technical content of the present invention is further described:

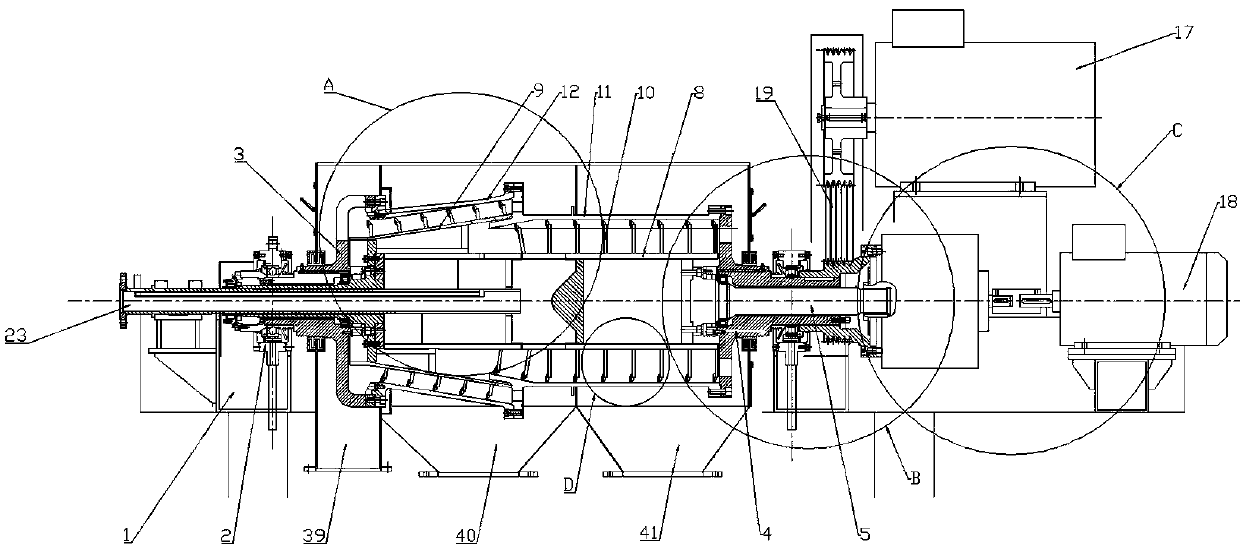

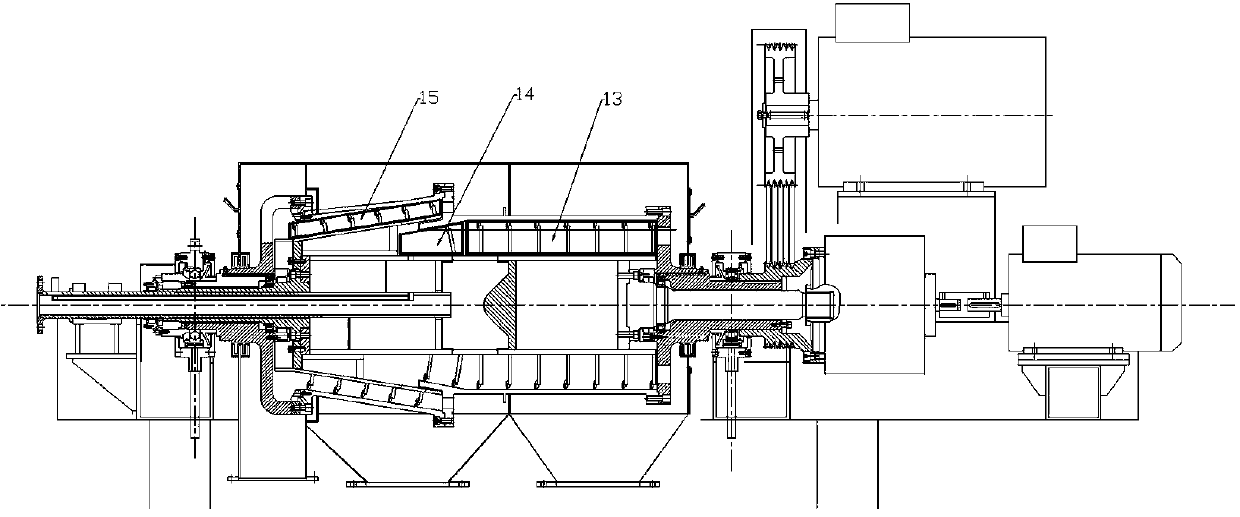

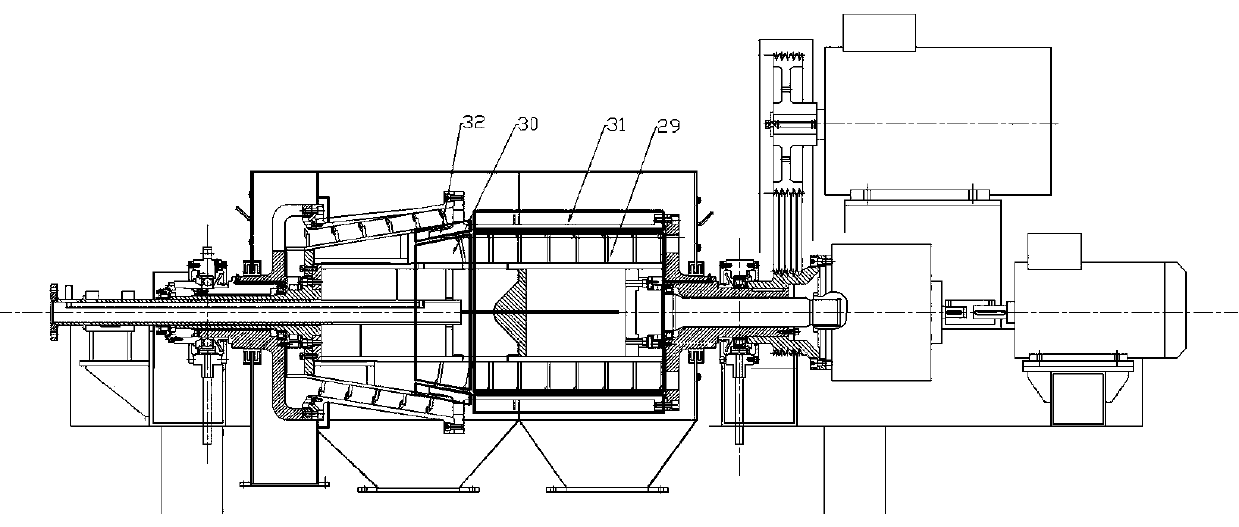

[0025] Figure 1~7 A horizontal double-cone spiral decanter centrifuge of the present invention is shown, comprising:

[0026] Rack 1, multiple bearing housings 2, small end journal 3, large end journal 4, mandrel 5, primary screw journal 6, secondary screw journal 7, primary screw 8, secondary screw 9, Multiple spiral blades 10, primary drum 11, secondary drum 12, primary settling area 13, primary drying area 14, secondary drying area 15, casing 16, main motor 17, auxiliary motor 18, multiple V-belt 19, drum pulley 20, differential 21, coupling 22, feed pipe 23, multiple primary screw outlets 24, multiple secondary screw outlets 25, multiple primary rotors Drum weir plate 26, multiple secondary drum weir plates 27, drum solid phase outlet 28, primary spiral 8 includes primary spiral straight section 29 and primary spiral conical section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com