Low-temperature concentration method for liquid materials

A liquid material, low-temperature concentration technology, applied in separation methods, chemical instruments and methods, food science, etc., can solve problems such as insufficient concentration, increase processing costs, and affect quality, so as to promote the post-ripening process, accelerate evaporation, and accelerate moisture. The effect of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

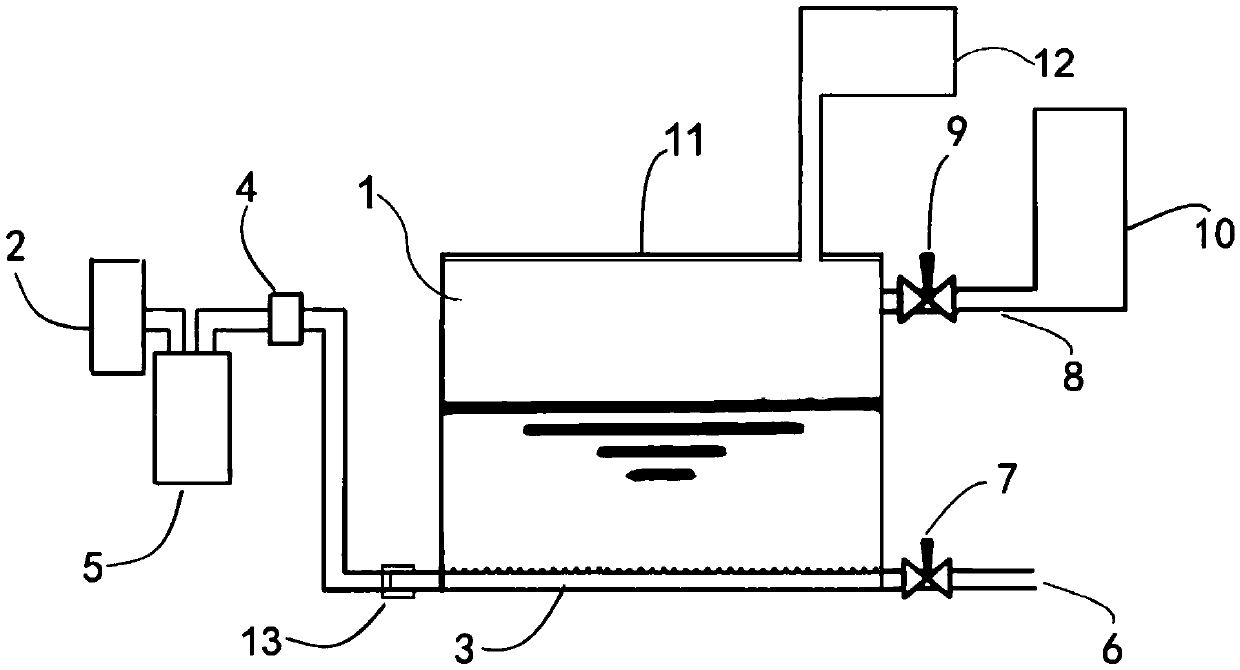

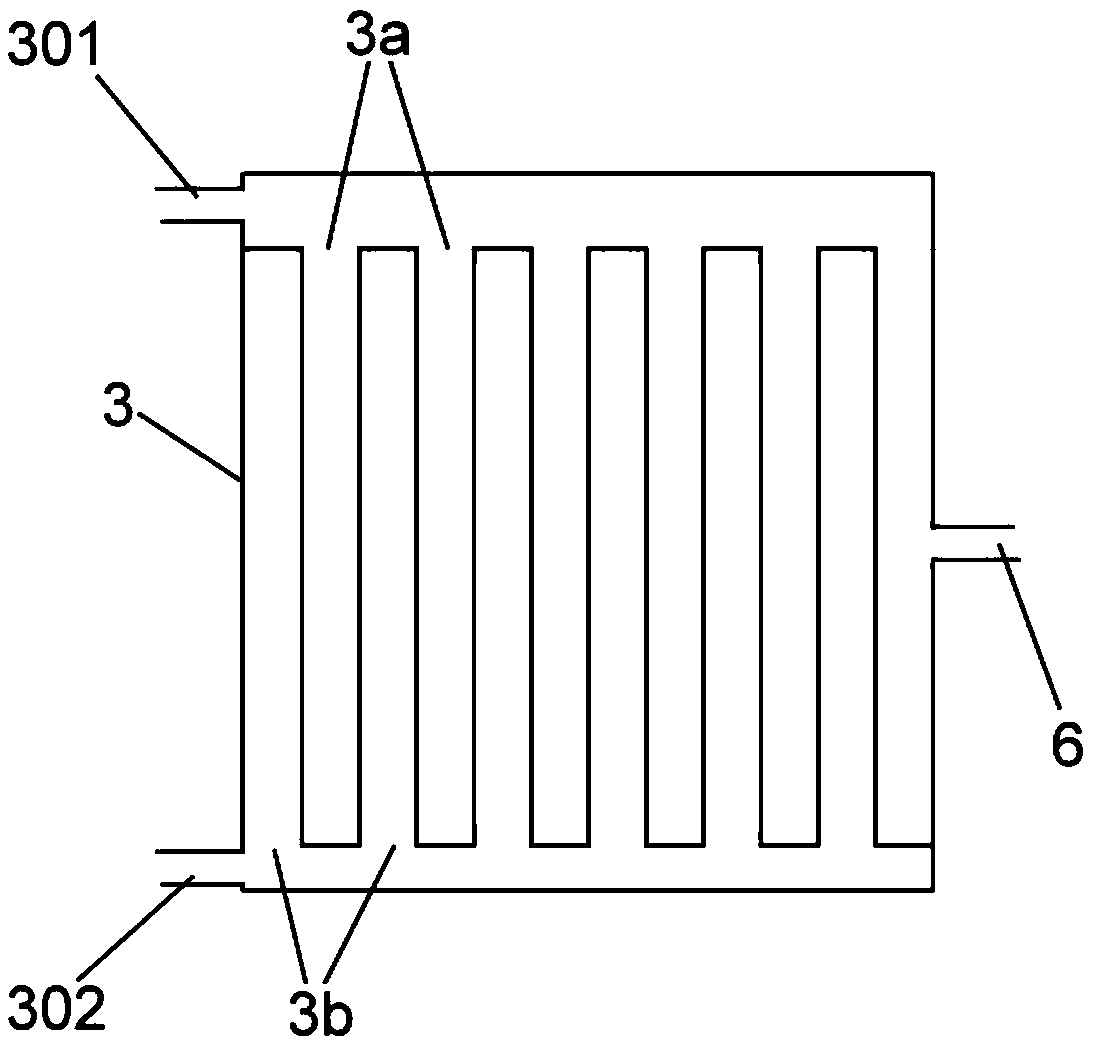

[0022] Such as figure 1 As shown, a low-temperature concentration device includes a boiling pool 1, a blower 2, a two-position three-way solenoid valve 13, a hollow porous plate 3, a heater 4, a dust collector 5, a cover plate 11 and a negative pressure fan 12. The cover plate 11 is covered on the boiling pool 1, and the cover plate 11 is connected with a ventilation pipe, and a negative pressure fan 12 is installed at one end of the ventilation pipe. The blower 1 is connected to the inlet of the two-position three-way solenoid valve 13 through a pipeline, and the two outlets of the two-position three-way solenoid valve 13 are respectively connected to the first intake pipe 301 and the second intake pipe 302, and the solenoid valve controller controls the two-position The three-way solenoid valve 13 cycles and alternately opens the two outlets so that the first intake pipe 301 and the second intake pipe 302 communicate with the blower 2 alternately. The hollow perforated plat...

Embodiment 2

[0027] Utilize the method for concentrating the raw honey of the low-temperature concentrating device in embodiment 1, comprise steps:

[0028] S1: Open the second control valve 9, feed the raw honey in the storage tank 10 into the boiling pool 1 through the feeding pipe 8, and then close the second control valve 9;

[0029] S2: turn on the dust collector 5, the blower 2, the heater 4 and the negative pressure fan 12 in sequence;

[0030] S3: Turn on the controller of the two-position three-way solenoid valve 13, open the two outlets of the two-position three-way solenoid valve 13 alternately in a cycle to make the first air intake pipe 301 and the second air intake pipe 302 communicate with the blower 2 alternately, so that the first The interval 3a and the second interval 3b generate bubbles alternately, and the raw honey is concentrated by blowing and boiling at low temperature;

[0031] S4: After the raw honey is concentrated into honey that can be filled, the first contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com