Mulberry paste and production process thereof

A production process and a technology for mulberry paste, applied in the field of mulberry paste and its production process, can solve the problems of easily damaged mulberry fruit active ingredients, incomplete removal of impurities, and high concentration temperature, so as to ensure the purity of paste and high retention rate of active ingredients , The effect of low extraction and concentration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

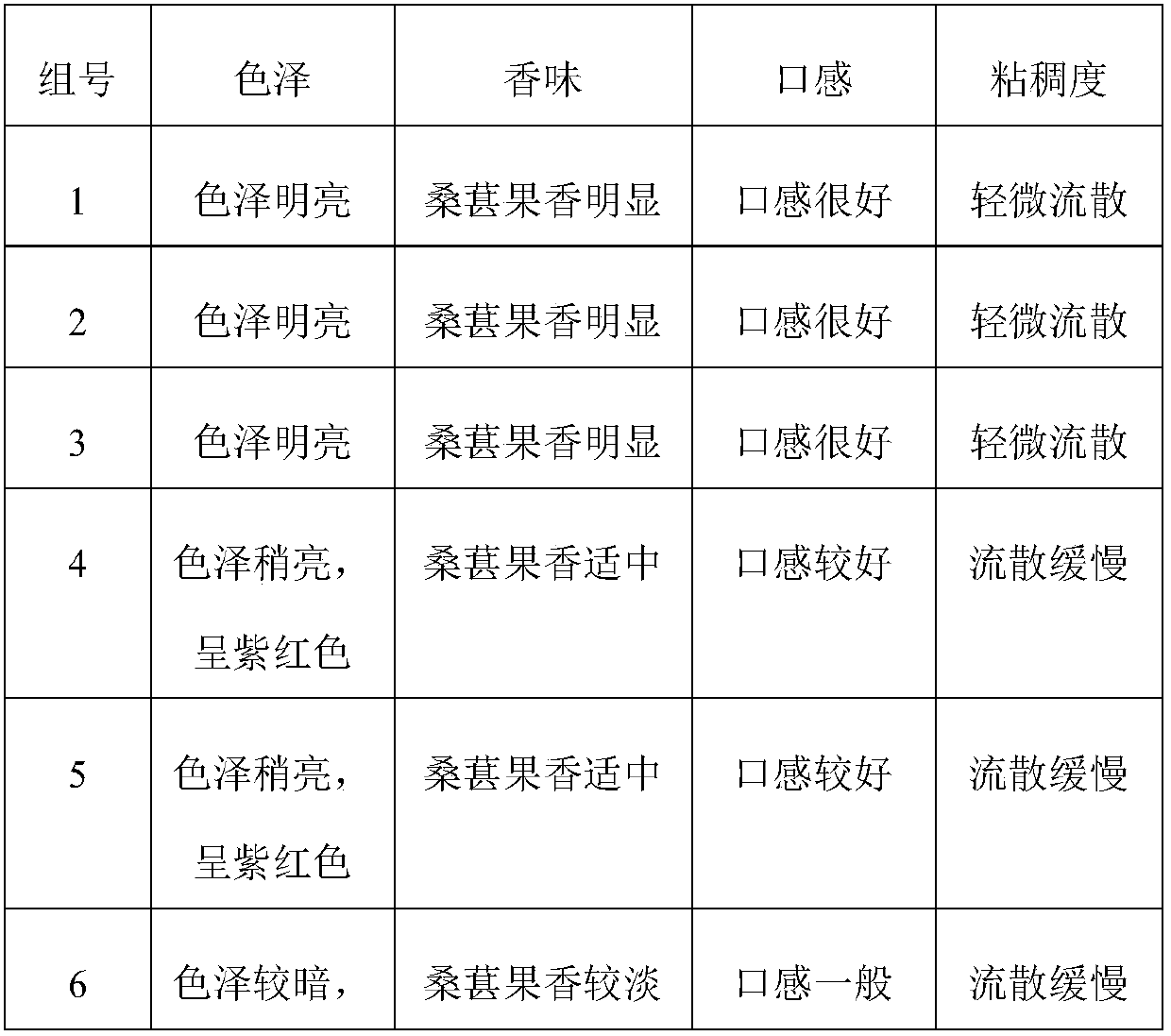

Examples

Embodiment 1

[0026] The present embodiment provides a kind of mulberry cream production process, comprises the following steps:

[0027] The mulberries were extracted countercurrently in a solvent at 55°C to obtain the extract; after the extract was subjected to decanter centrifugation, the filter cloth with a particle size of 4.8um was filtered for the first time to obtain the first filtrate; the first After the filtrate is disc-centrifuged, the second filtrate is filtered through the filter cloth with a particle size of 0.8um to obtain the second filtrate; the second filtrate is membrane-concentrated at 35°C to obtain the first concentrate; the first The concentrated solution is subjected to single-effect concentration under negative pressure at 60° C. to obtain the second concentrated solution; then the second concentrated solution is vacuum aseptically filled.

Embodiment 2

[0029] The present embodiment provides a kind of mulberry cream production process, comprises the following steps:

[0030] The mulberries were extracted countercurrently in a solvent at 60°C to obtain the extract; after the extract was subjected to decanter centrifugation, the filter cloth was filtered for the first time with a particle size of 5.2um to obtain the first filtrate; the first After the filtrate is disc-centrifuged, the second filtrate is filtered through the filter cloth with a particle size of 1.2um to obtain the second filtrate; the second filtrate is membrane-concentrated at 40°C to obtain the first concentrate; the first The concentrated solution is single-effect concentrated under negative pressure at 65°C to obtain the second concentrated solution; then the second concentrated solution is vacuum aseptically filled.

Embodiment 3

[0032] The present embodiment provides a kind of mulberry cream production process, comprises the following steps:

[0033] The mulberry is extracted countercurrently in a solvent at 58°C to obtain the extract; after the extract is subjected to decanter centrifugation, the filter cloth with a particle size of 5um is filtered for the first time to obtain the first filter; the first filter After the liquid is subjected to disc centrifugation, the filter cloth with a permeable particle size of 1um is filtered for the second time to obtain the second filtrate; the second filtrate is membrane-concentrated at 38°C to obtain the first concentrated liquid; the first concentrated liquid Single-effect concentration was carried out at 63°C under negative pressure to obtain the second concentrated solution; then the second concentrated solution was vacuum aseptically filled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com