A method and a system for managing a prefabricated component warehouse based on RFID technology

A technology of prefabricated components and management methods, applied in data processing applications, computer parts, collaborative devices, etc., can solve the problems of limited reading and recording functions, inability to ensure information accuracy and real-time, and high error probability, etc. Achieve the effect of paperless management, traceability, and management information sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Now the present invention is further described in conjunction with description of drawings and embodiments:

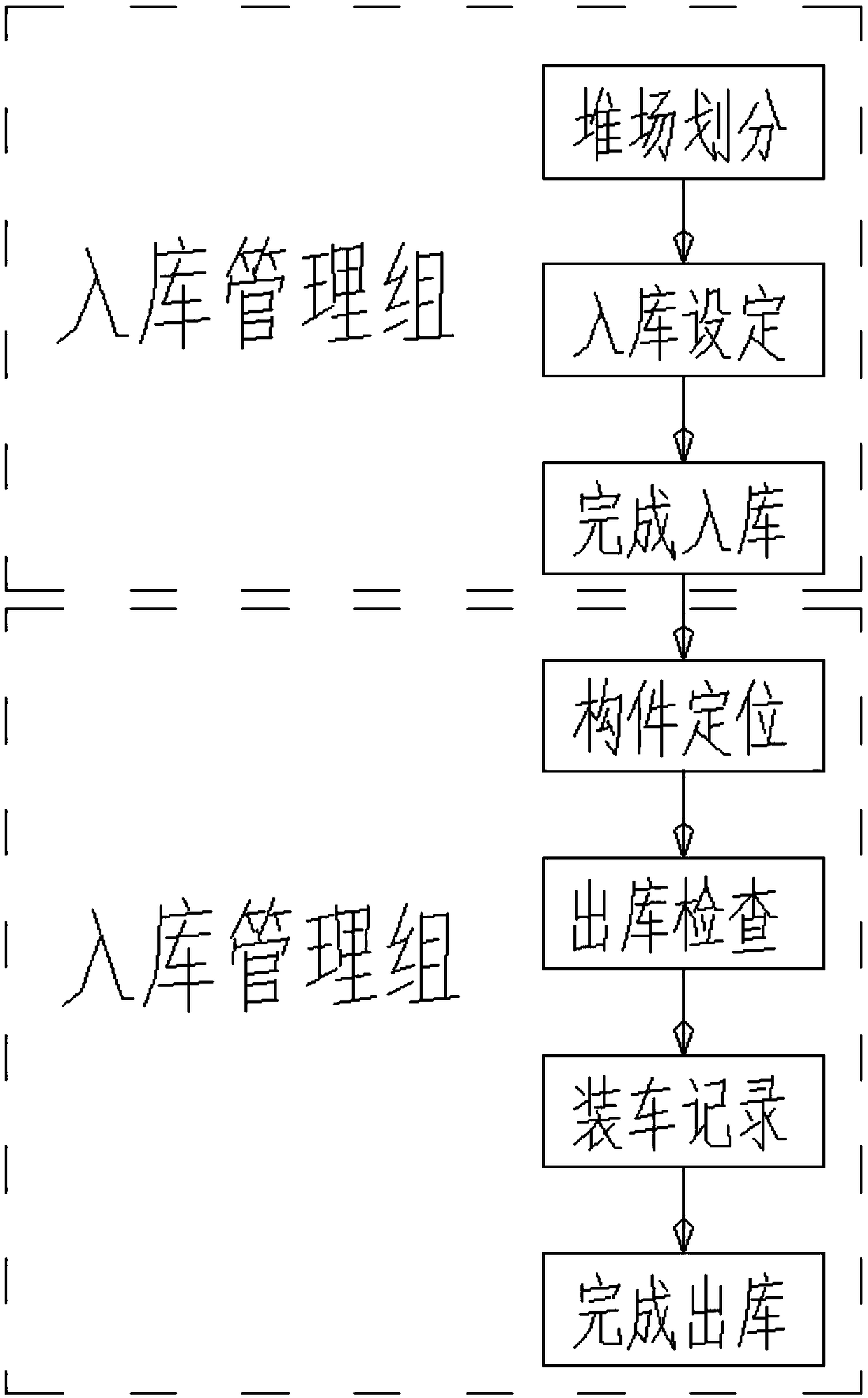

[0039] A prefabricated component warehouse entry and exit management method and system based on RFID technology, which includes a warehouse entry management group and a warehouse exit management group, wherein the warehouse entry management group includes the following steps:

[0040] The yard division divides the prefabricated component yard by project name or type or combination, and divides it into several secondary areas, and then divides the prefabricated component storage or external dimensions in the secondary area into several three-level areas. In the three-level area, the first RFID chip and the corresponding unique positioning number are set in the three-level area, and the unique positioning number is written in the first RFID chip; in the yard division step, the three-dimensional digital model of the yard is established, and the first The informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com