Circuit for detecting voltage changing rate of two ends of thyristor

A technology of voltage change rate and detection circuit, which is applied in the direction of change rate measurement, etc., can solve the problems of increasing the capacity of the resistance-capacitance absorption circuit, limited ability to suppress dv/dt, and increasing the overall loss of thyristor devices, etc., achieving a simple and reliable principle and fewer devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

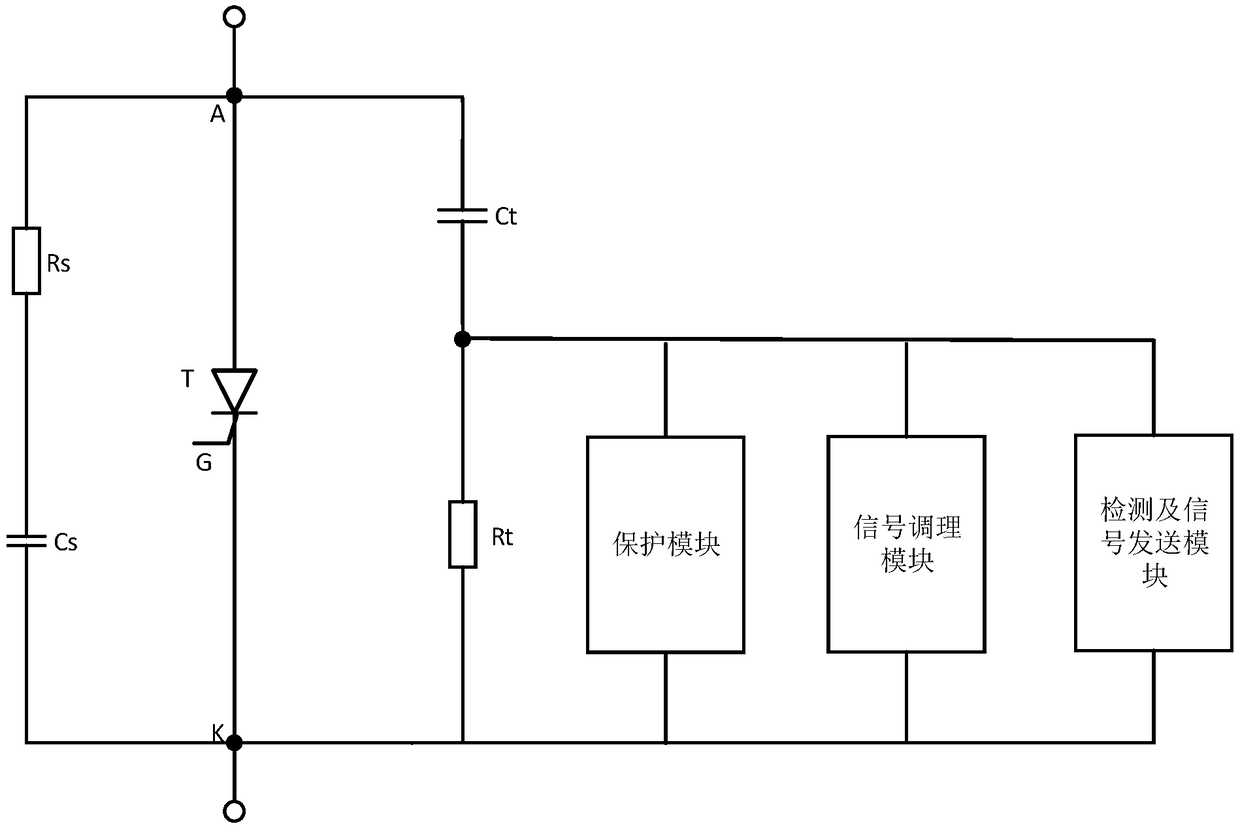

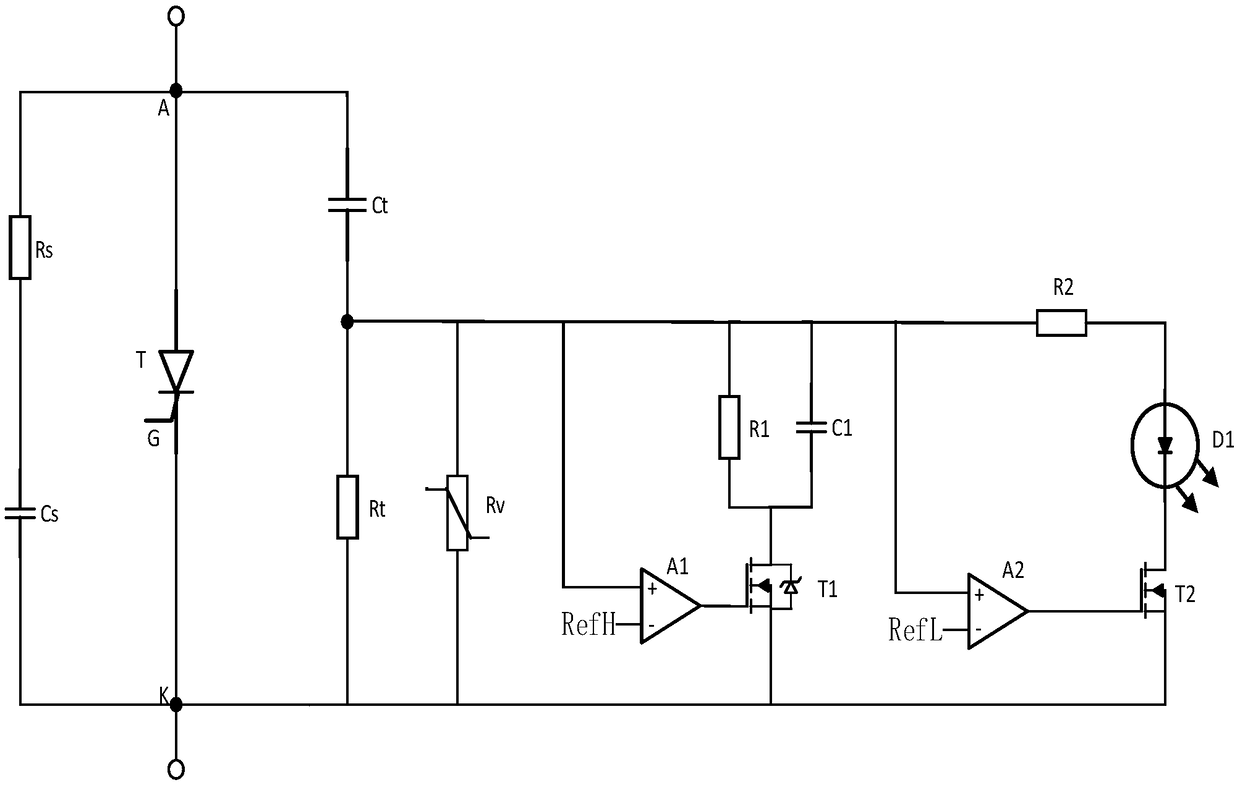

[0015] Such as figure 1 and figure 2 As shown, a detection circuit for the voltage change rate at both ends of a thyristor, including a capacitor Ct and a sampling resistor Rt connected in series across the two ends of the thyristor T, and a protection module, a signal conditioning module and a dv / dt detection module connected in parallel at both ends of the sampling resistor Rt and signal sending module.

[0016] The capacitor Ct and the sampling resistor Rt are connected in series across the two ends of the thyristor. The change of the voltage across the thyristor T makes the capacitor Ct generate a current proportional to the voltage change rate. The dv / dt of the voltage across the thyristor T can be obtained from the magnit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com