Surface flaw detection marking apparatus and method for absorber piston rod of automobile shock based on vision

A technology for detecting marks and surface defects, which is applied in the field of detection and marking devices for surface defects of automobile shock absorber piston rods. Effect of tact reduction and improvement of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

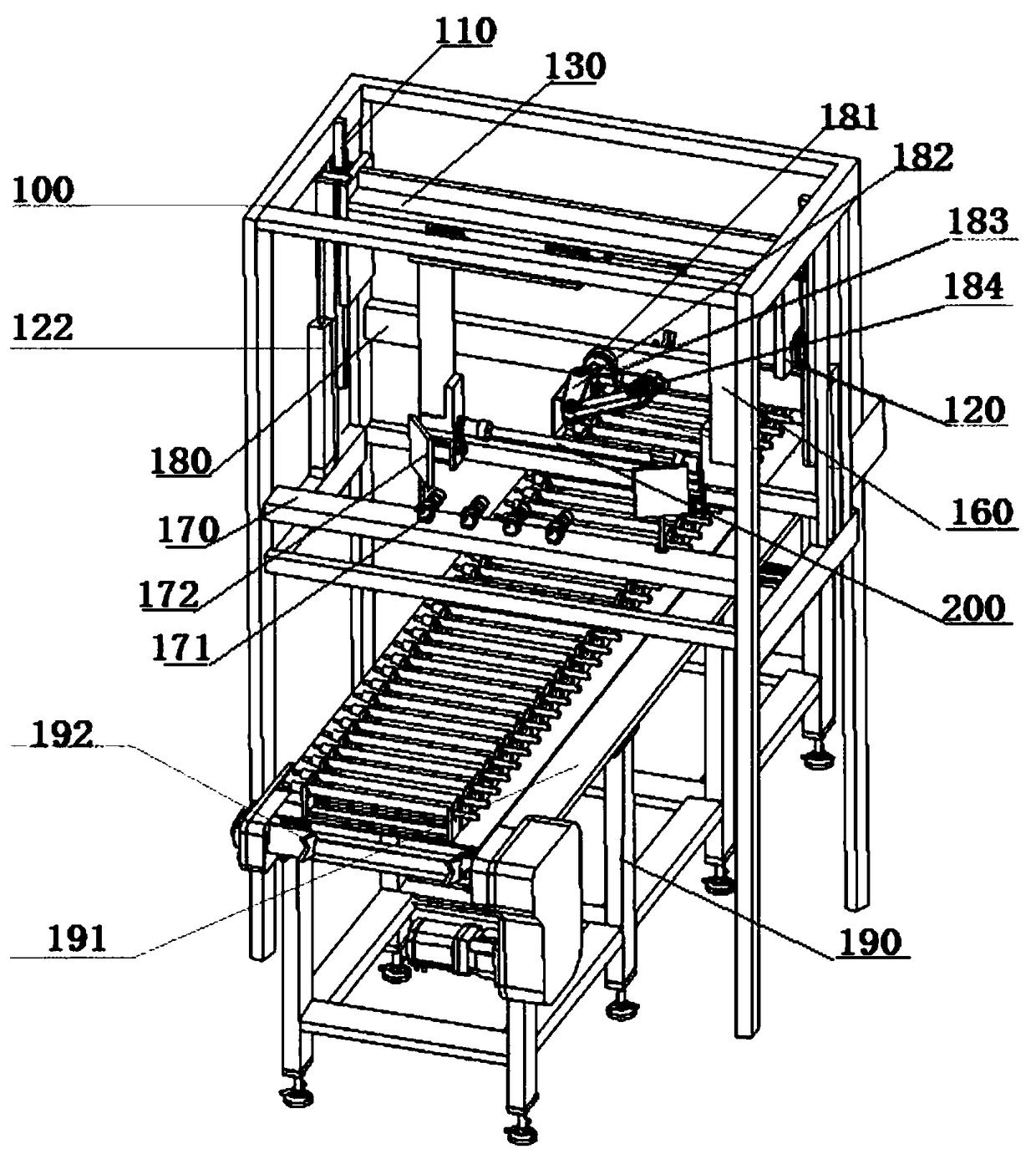

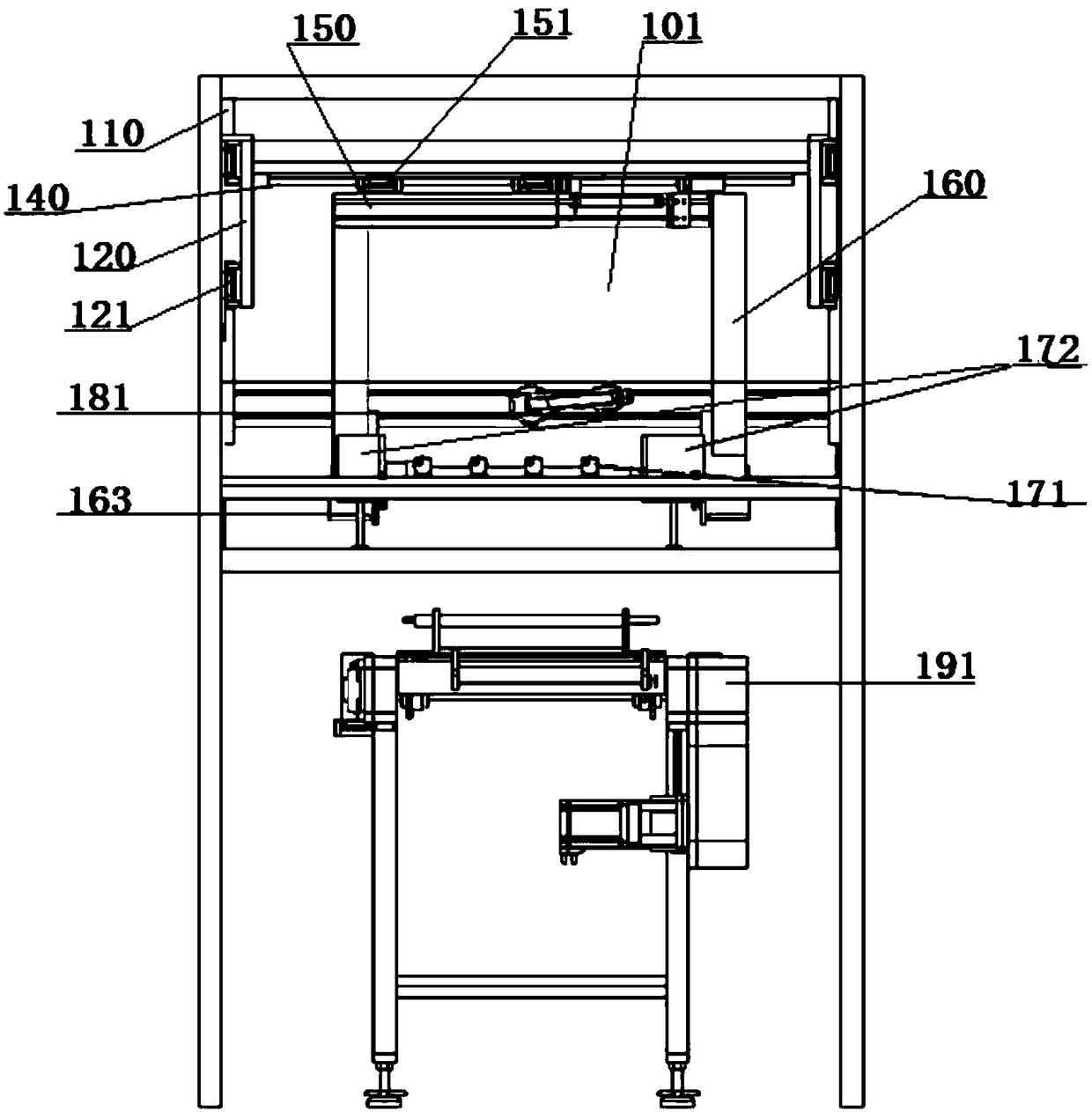

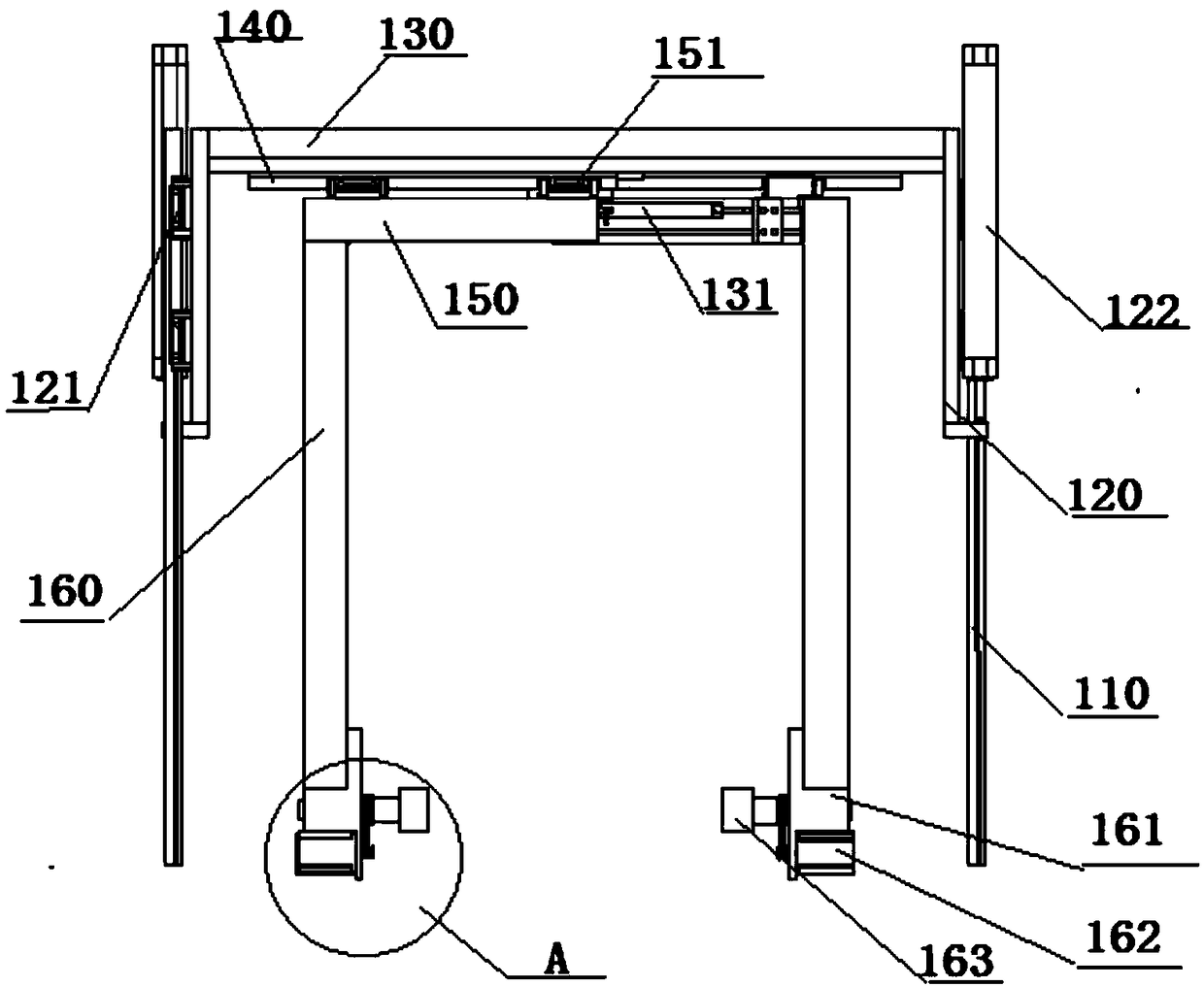

[0071] Such as Figure 1-12 As shown, the present invention provides a vision-based detection and marking device for surface defects of automobile shock absorber piston rods, including: a frame body 100; The upper side of the middle part; the upper and lower sliders 120, which are symmetrically arranged between the first guide rails 110, and are respectively slidably connected with the adjacent first guide rails 110, and the upper and lower sliders 120 are connected by the first upper and lower sliders 121 The first guide rail 110 is slidably connected, and the upper and lower sliders 120 can move axially along the first guide rail 110; When moving axially along the first slide rail 110 , it can drive the connecting plate 130 to move axially along the first guide rail 110 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com