Glass collecting device for discharging of high temperature viscosity test

A collection device and viscosity technology, which is applied in the field of glass collection devices for high temperature viscosity test and discharge, can solve the problems of easy sticking to refractory plates, blockage of sewer pipes, water leakage, etc., and achieves the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

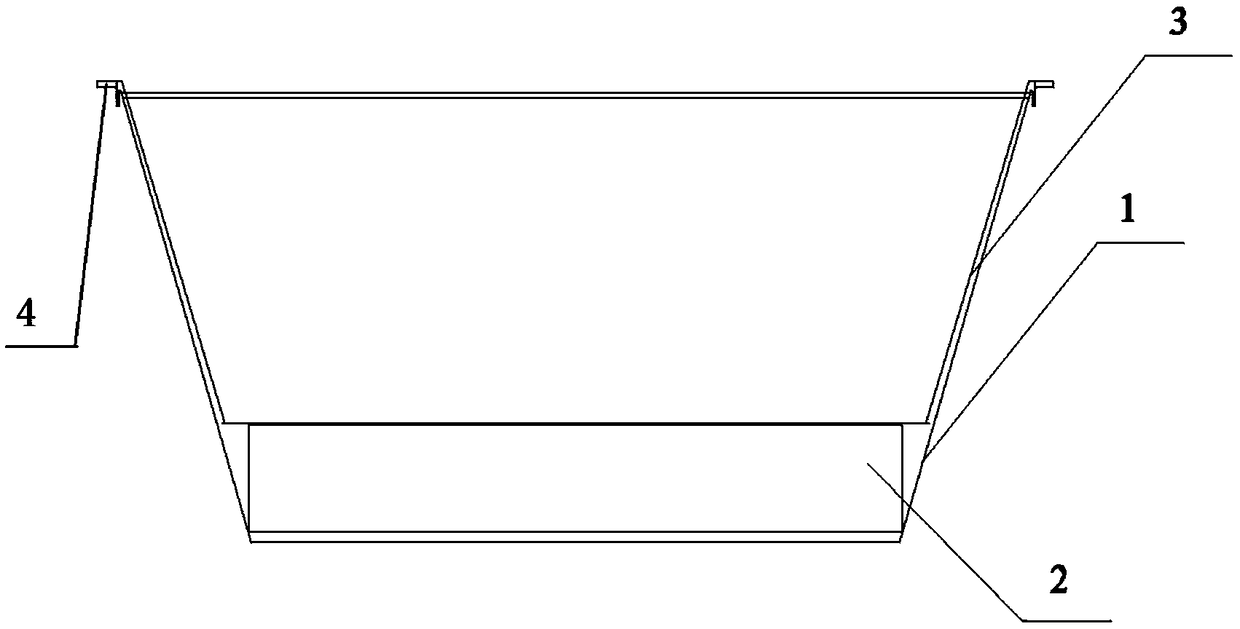

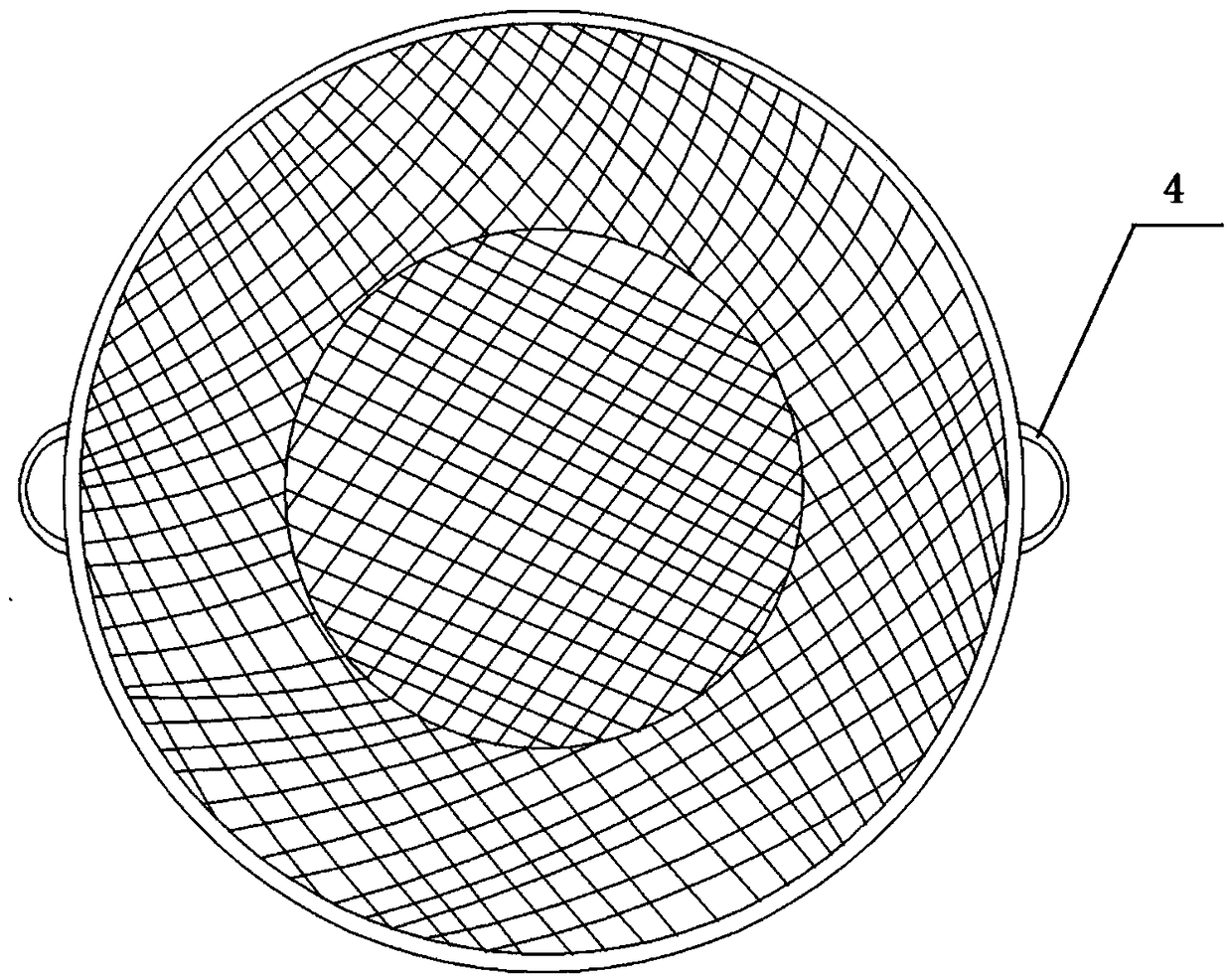

[0027] Such as figure 1 As shown, a glass collection device for high-temperature viscosity test discharge includes a conical metal collection box 1 , a refractory plate or brick, and a dense screen 3 . The collection box 1 is used as the bottom body of the glass collection device, with the small circle facing down and the large circle on top; the refractory board or refractory brick is just embedded in the collection box 1 according to the size of the collection box 1, and the size of its bottom surface is the same as that of the bottom surface of the collection box 1. The same; the screen 3 is embedded in the collection box 1, the side is attached to the inner wall of the collection box 1, and the bottom is in contact with the upper surface of the refractory board or refractory brick, which ensures that after the glass solution is poured into the device, it will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com