A device for synchronous grouting prestressed pipe pile

A prestressed pipe pile and synchronous grouting technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem that the grouting outlet is easily blocked by soil, and the pipe pile and the soil layer are not effectively fixed. and other problems, to achieve the effect of improving the fixing effect, convenient docking and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

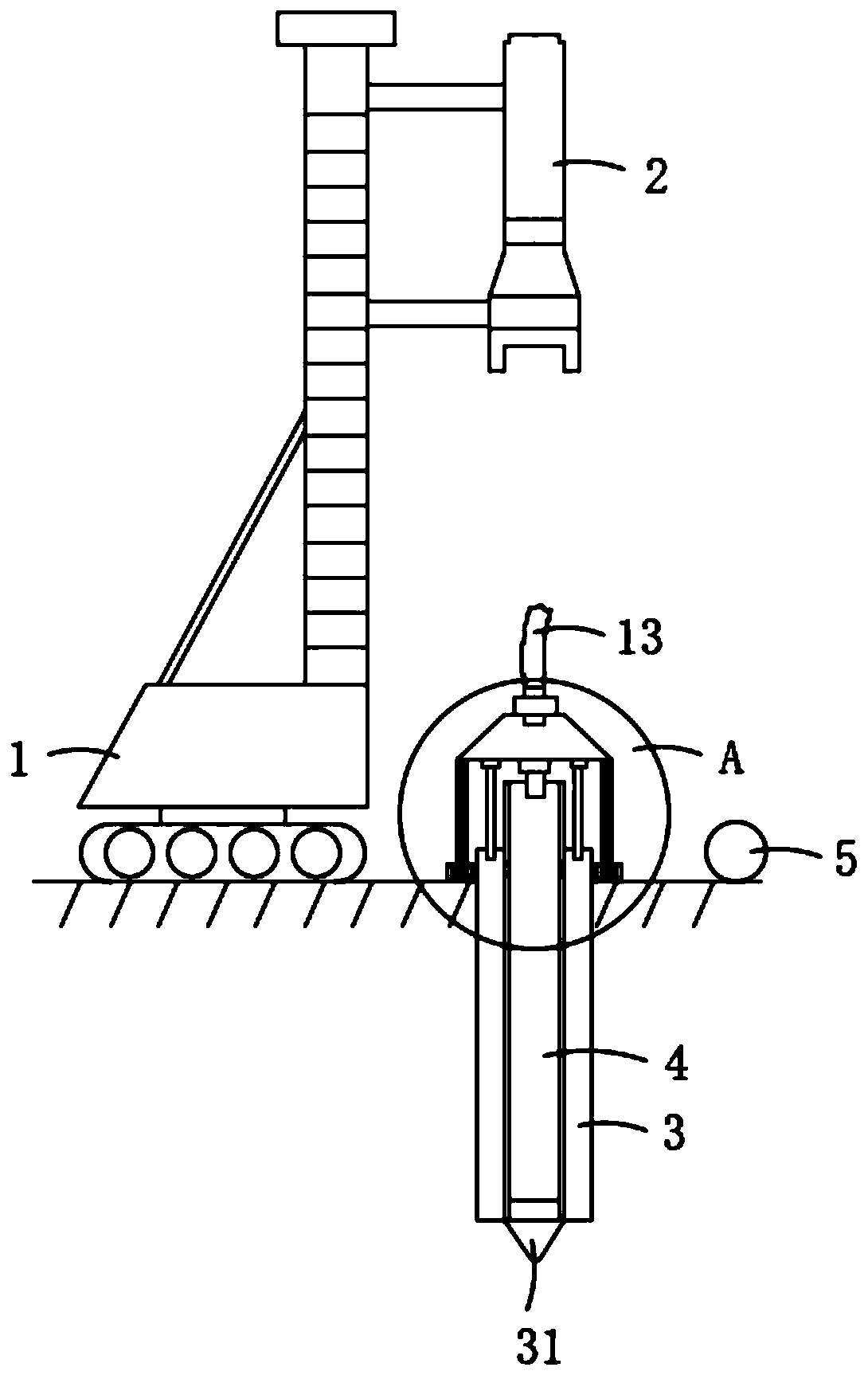

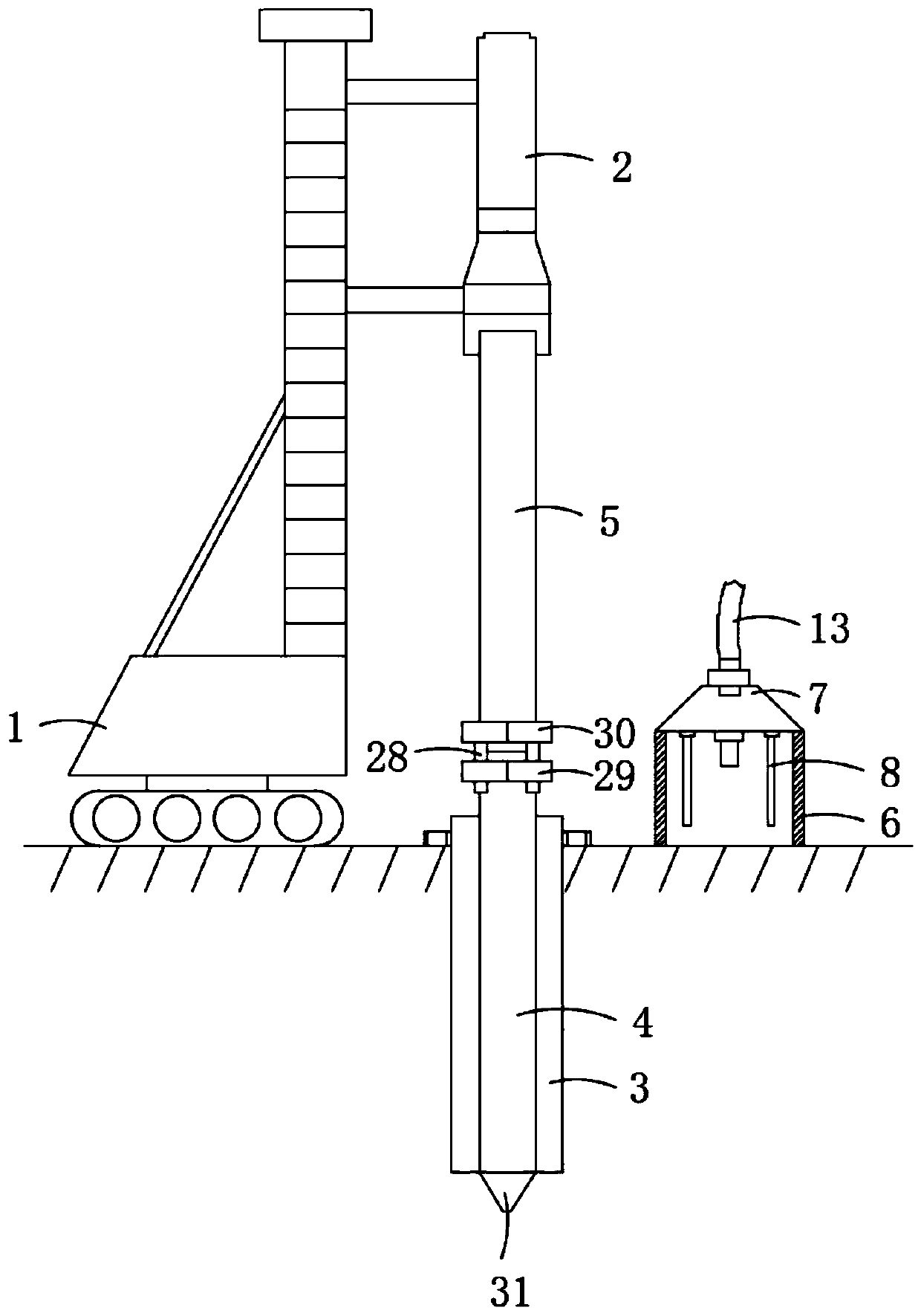

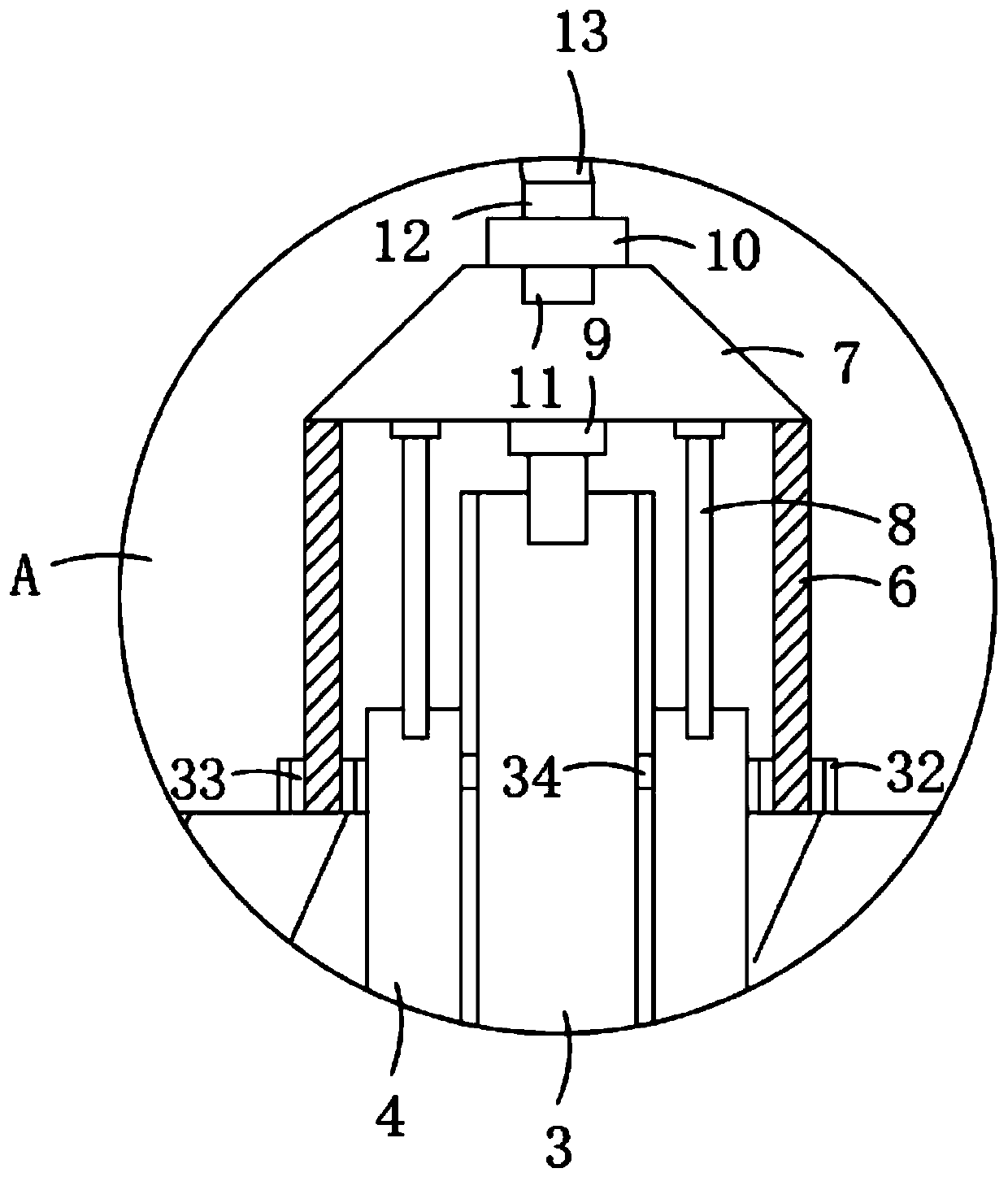

[0027] refer to Figure 1-6 , a device for synchronous grouting prestressed pipe piles, comprising a pile driver 1, a piling hammer 2, a grouting outer pipe 3, a first pipe pile 4, a second pipe pile 5 and a grouting structure, the grouting outer pipe 3. A hollow structure with both ends connected is adopted. The lower end of the first pipe pile 4 is located in the grouting outer pipe 3. The grouting structure includes a support frame 6, a grouting chamber 7, a grouting branch pipe 8, an electromagnetic valve 9, and a pipe connector 10 , the pulp outlet pipe 11, the second pulp inlet pipe 12 and the first pulp inlet pipe 13.

[0028] The upper ends of the four suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com