Construction method and equipment of circular bored socketed piles

A construction method and technology of rock-socketed piles are applied in drilling equipment, sheet pile walls, earthwork drilling, etc., to improve drilling efficiency, solve construction problems, and improve hole quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] like Figure 1-5 As shown, the construction method of the annular bored rock-socketed pile specifically includes the following steps:

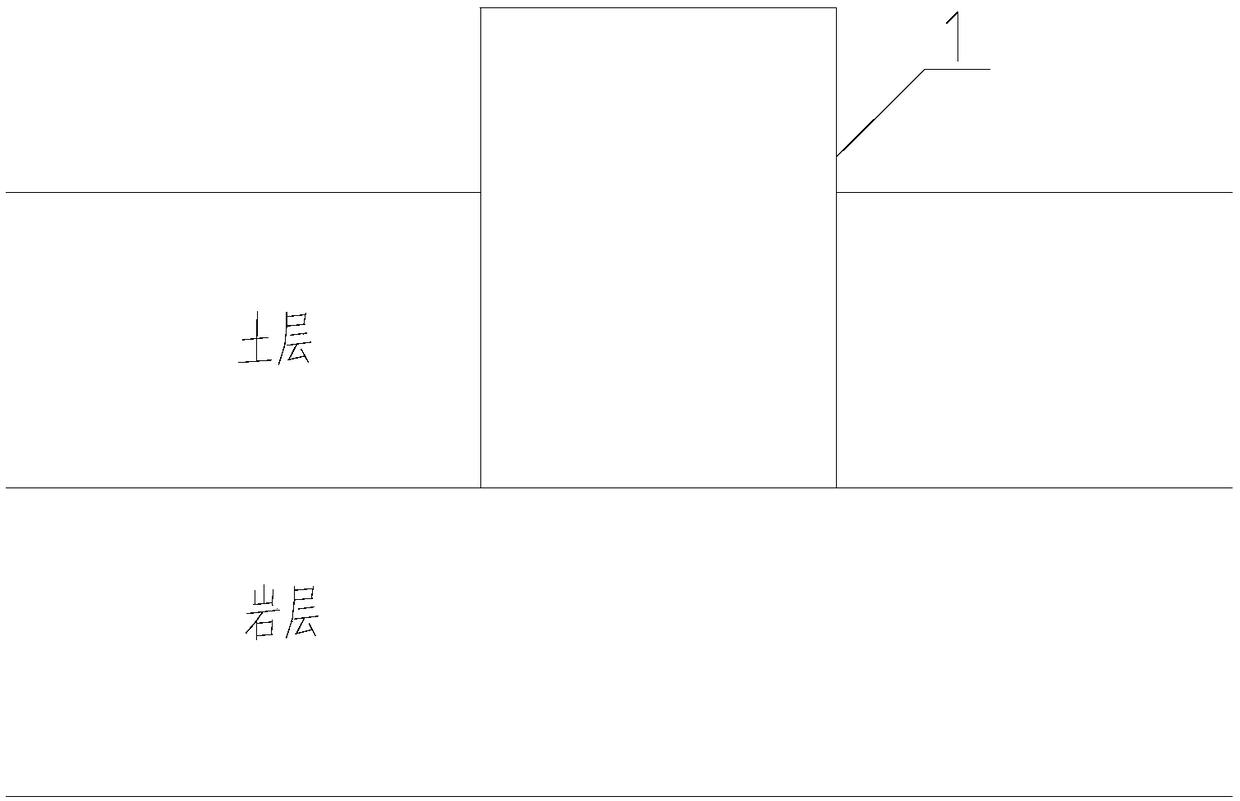

[0035] Step 1, such as figure 1 As shown, the steel casing 1 is hoisted to the top of the construction site by lifting equipment, and the steel casing 1 is driven by the lifting piling hammer until the bottom end of the steel casing 1 reaches the top surface of the rock formation, and the steel casing 1 The setting position should ensure that the centerline of the steel casing 1 coincides with the centerline of the pile position; wherein, the steel casing 1 is a cylinder structure, and its height is greater than the depth of the soil layer at the construction location, so that the top end surface remains still after the setting is completed. a distance above the soil layer;

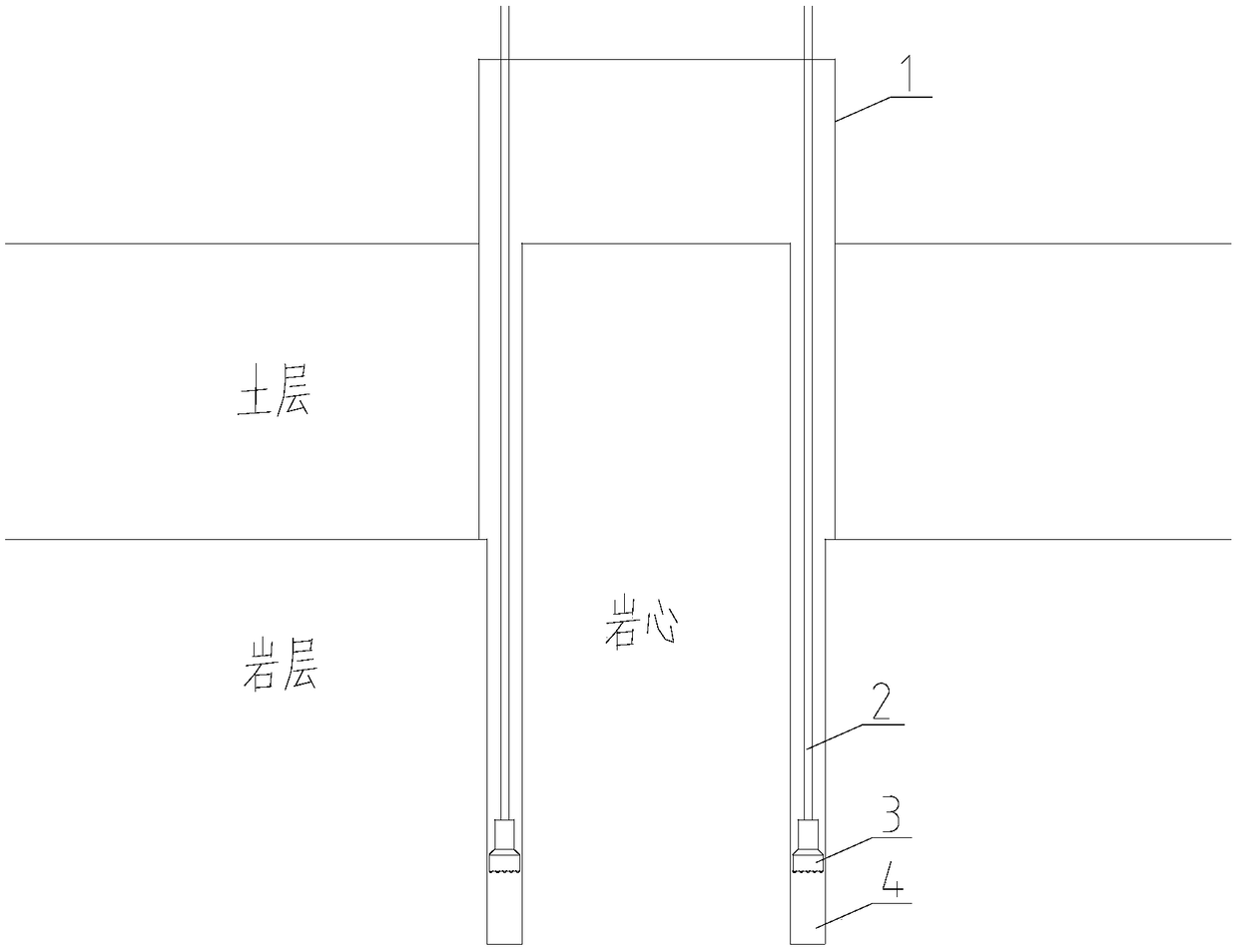

[0036] Step two, such as figure 2 As shown, lift away the piling hammer, set up the drilling rig, through the drill pipe 2 of each down-the-hole hammer 3, a pl...

Embodiment 2

[0044] like Figure 6~7 As shown, the annular combined down-the-hole hammer drilling equipment suitable for rock-socketed pile construction includes a drilling rig connection end 9, a steel truss 7, an annular chassis 8, a plurality of drill rods 2 and a plurality of Down-the-hole hammer 3; wherein, the connection end 9 of the drilling rig, the steel truss 7 and the annular chassis 8 are welded and fixed in sequence;

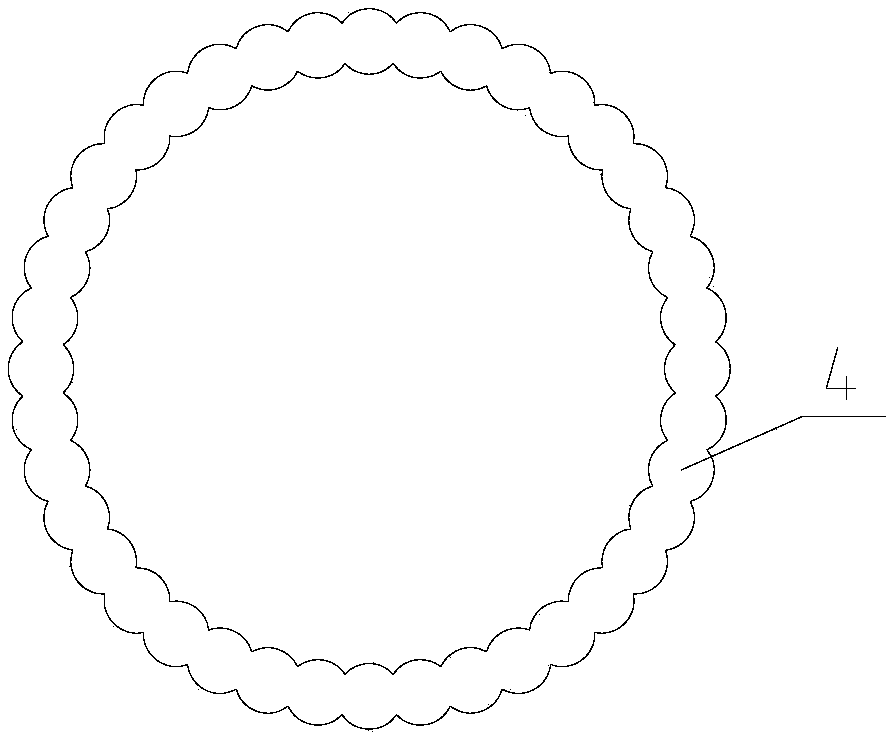

[0045] like Figure 7As shown, a plurality of interfaces 10 consistent with the number of drill pipes are evenly distributed along the circumferential direction on the annular chassis 8 and adjacent to the edge, and a connecting flange is welded at each interface 10 from the bottom of the annular chassis 8;

[0046] Each drill rod 2 is vertically arranged below the annular chassis 8, and is evenly distributed along the circumferential direction of the annular chassis 8, and the top end of each drill rod 2 is provided with the same connection flange type as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com