Vibrating punching machine with returned oil cooling structure

A vibrator and oil cooling technology, applied in basic structure engineering, soil protection, construction, etc., can solve the problems of maintenance personnel burns, waste of replacement time, frequent replacement, etc., and achieve the effect of reducing the cost of use and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

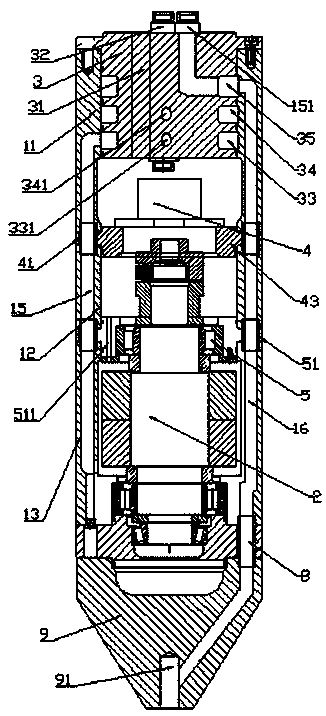

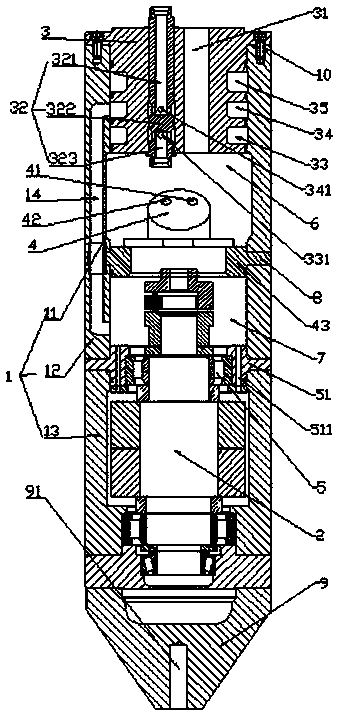

[0032] Such as figure 1 and figure 2 As shown, the vibrator with the oil return cooling structure of Embodiment 1 includes a vibrator cylinder 1, a vibrator main shaft 2 installed in the vibrator cylinder 1 through a bearing 5 and a vibrator embedded in the vibrator cylinder 1. The multi-port connection plate 3 in the vibrating cylinder 1 includes a motor shield 11, a connecting flange 12 and a cylinder 13 which are screwed in turn by screws 10, and the motor shield 11 is connected to the connecting flange 12 through a motor base 43, The connecting flange 12 is connected with the cylinder body 13 through the bearing seat 51;

[0033] The inner cavity of the vibrating cylinder 1 is divided into the first cavity 6 and the second cavity 7 by the bearing seat, the hydraulic motor 4 is arranged in the first cavity 6, the oil inlet 41 and the oil outlet 42 of the hydraulic motor 4 The system oil inlet connection 31 and the system oil return connection 32 are respectively connecte...

Embodiment 2

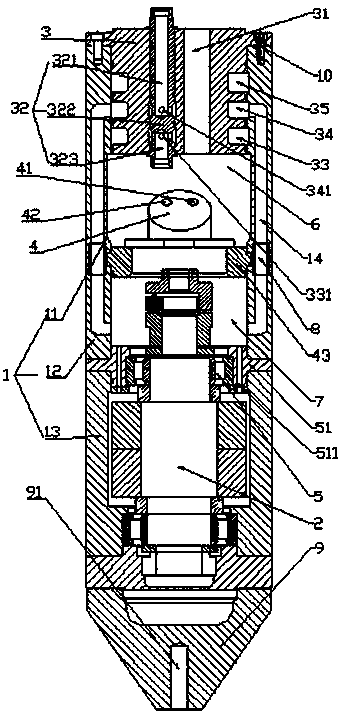

[0038] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that Embodiment 2 is provided with two system oil return channels.

[0039]Specifically, the number of motor oil return passages and / or the number of system oil return passages and / or the number of high pressure medium passages can also be set in multiples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com