Large coke oven thermal-state engineering fire scrabbling bed construction method

A construction method and coke oven technology are applied in the fields of transportation and firebed brick removal, which can solve the problems of high labor intensity, large labor, and long time for operators, and achieve the effects of simple structure, convenient production, and reduced engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The large-scale coke oven hot state engineering grilling bed construction method of the present invention comprises the following steps:

[0034] a. Make buckets and chutes for connecting bricks.

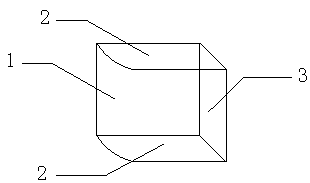

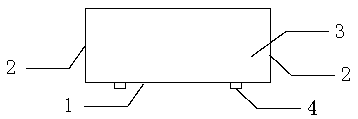

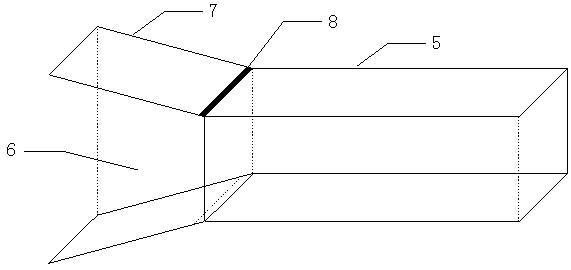

[0035] see now Figure 1-Figure 3 , figure 1 It is a schematic diagram of the structure of the brick-connecting bucket according to the embodiment of the present invention, figure 2 It is a schematic diagram of the arrangement of two channel steels at the bottom of the rectangular bottom plate of the brick bucket according to the embodiment of the present invention, image 3 It is a schematic diagram of the structure of the chute in the embodiment of the present invention.

[0036] According to the amount of bricks in each carbonization chamber of a large-scale coke oven, steel plates with a thickness of 5mm, 10# channel steel, and angle steel are used as production materials to process and manufacture brick-connecting buckets and chutes; Side panels, one end of the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com