Waste plastic crushing and reprocessing apparatus

A waste plastic and reprocessing technology, applied in the field of plastic production, can solve the problems of unstable operation of the crushing device, affecting the efficiency of crushing, device deviation, etc., so as to shorten the time of crushing, improve the efficiency of crushing, and reduce the volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

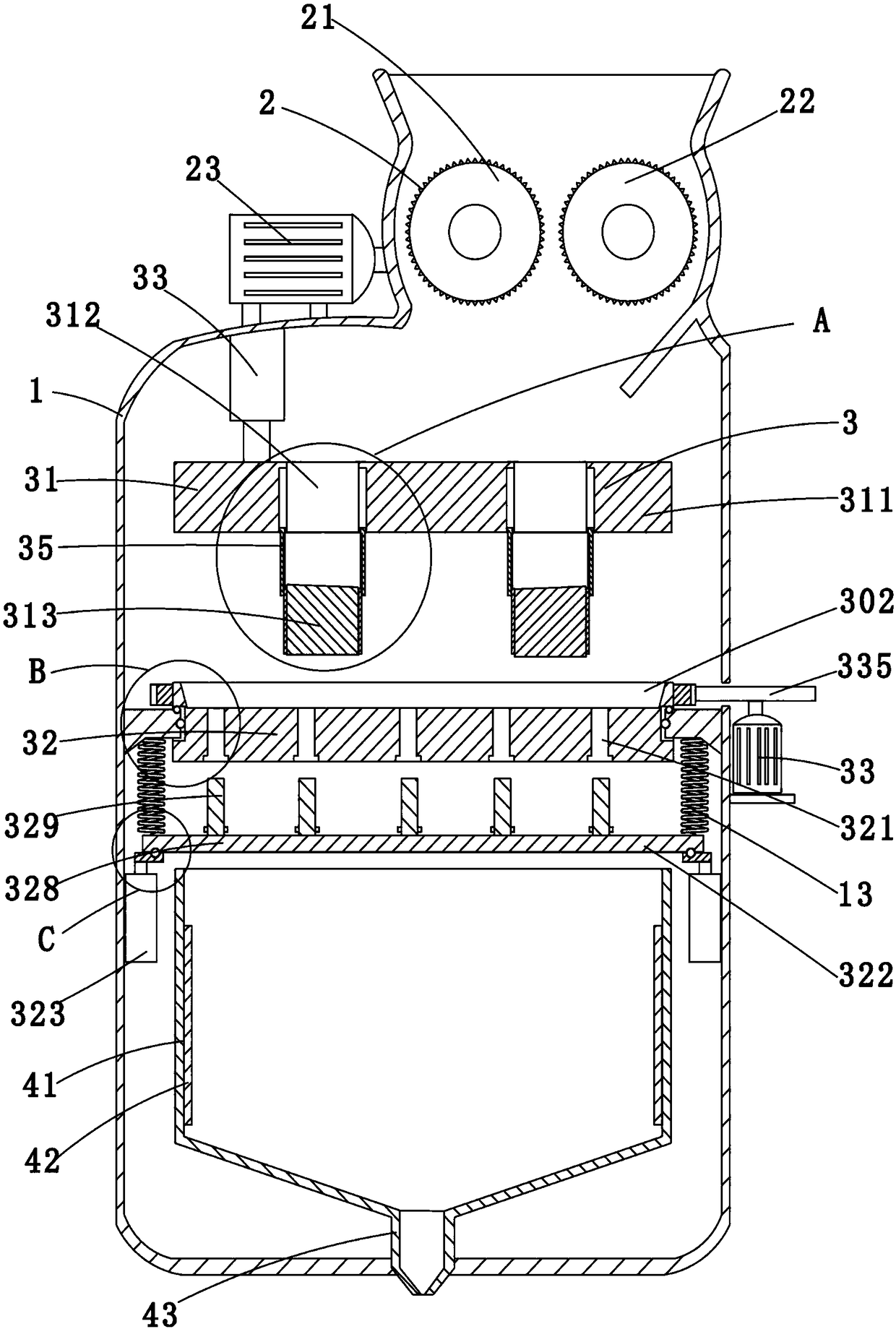

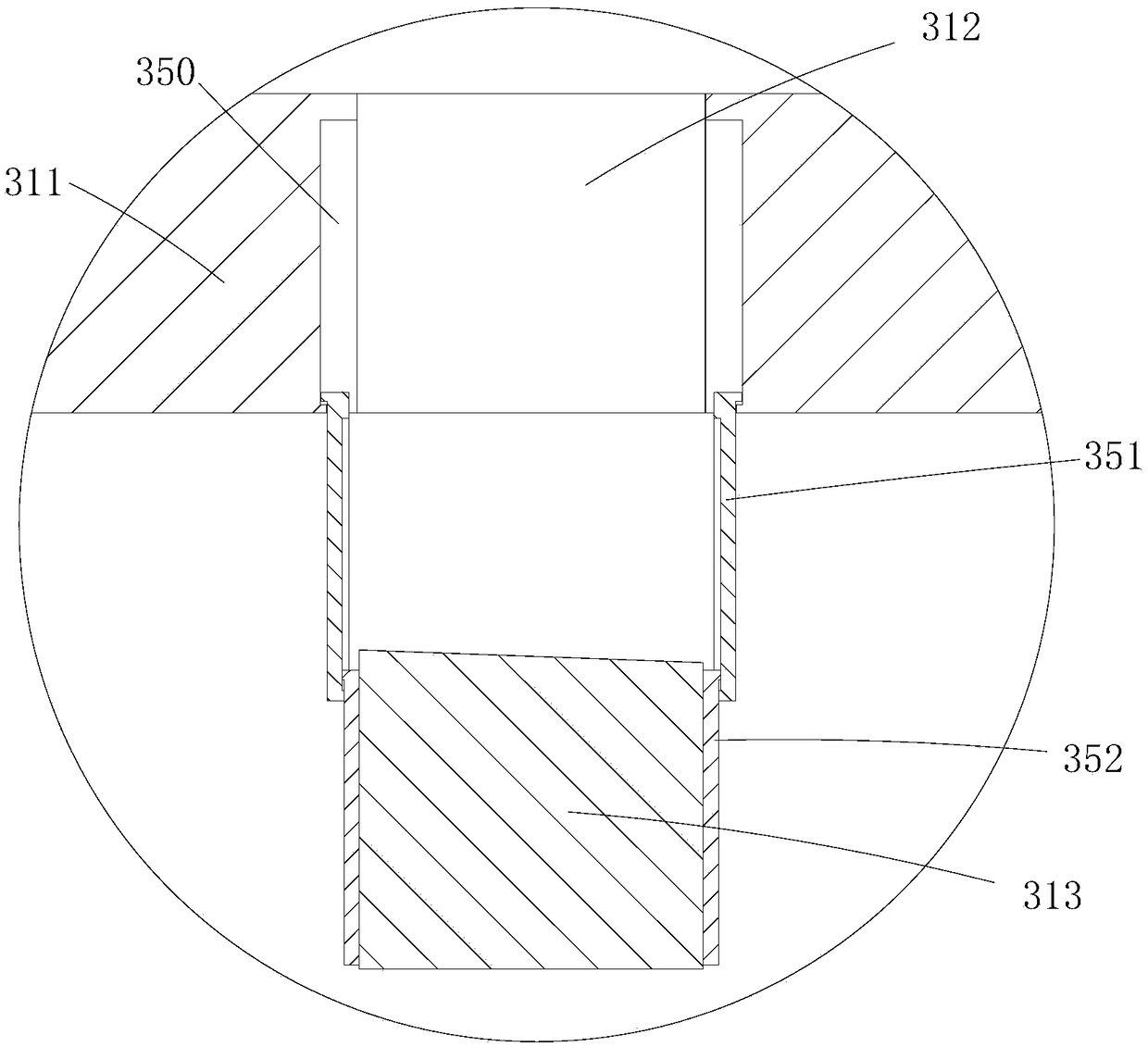

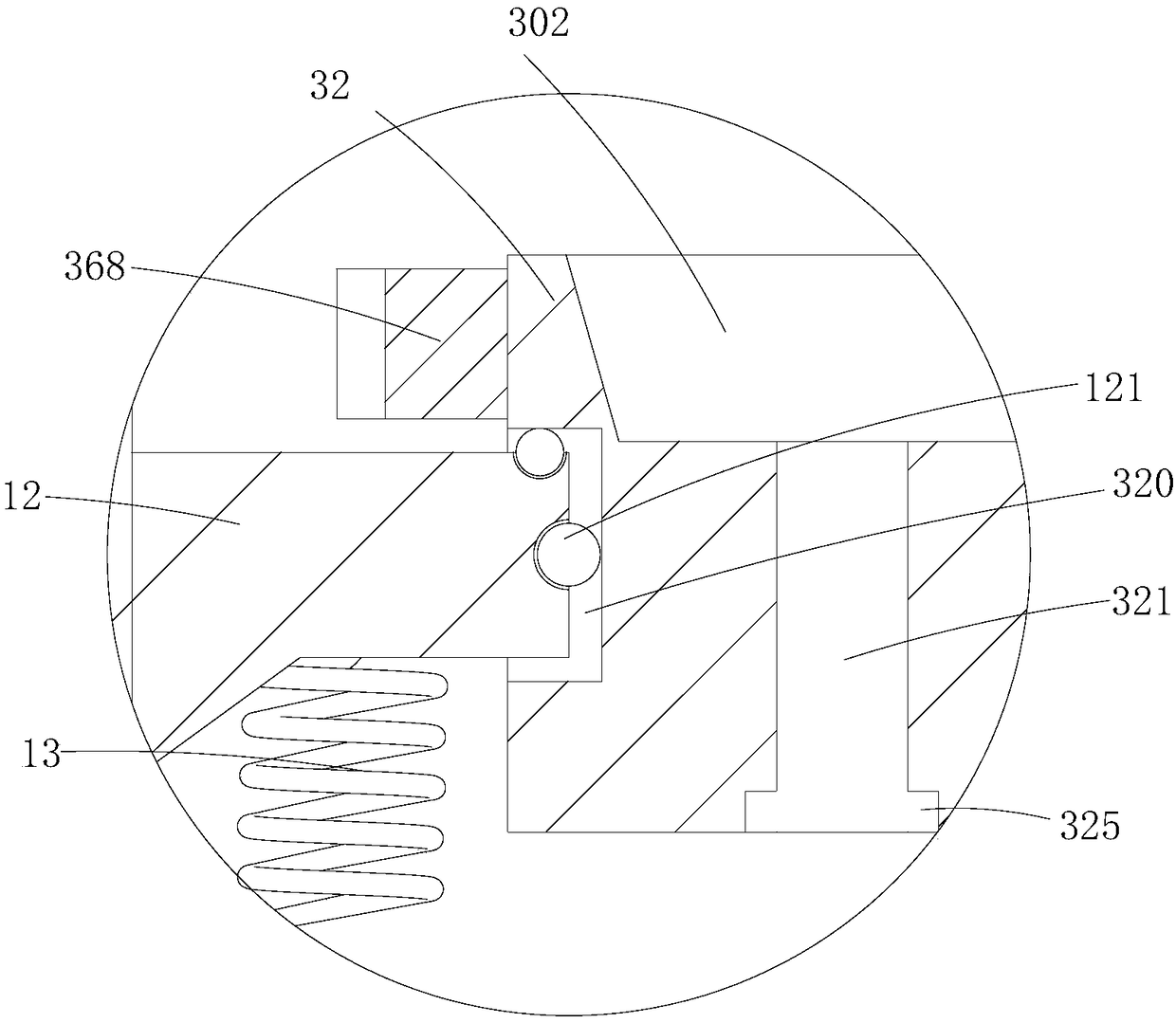

[0032] Such as Figure 1-7 As shown, a waste plastic crushing and reprocessing device includes a casing 1, a first crushing part 2, a second crushing part 3 and a hot-melt part 4, wherein the casing 1 is a metal shell; the first crushing part 2 is set on the upper part of the casing 1, and the waste plastics are coarsely crushed through the first crushing part 2; the first crushing part 2 includes a first crushing roller 21, a second crushing roller 22 and a motor 23, the The first and second crushing rollers are metal rollers, and the first crushing roller 21 and the second crushing roller 22 are provided with a plurality of crushing teeth, and the motor 23 is an existing motor on the market, and the motor 23 The first crushing roller 21 is driven to rotate clockwise by a metal gear, and the second crushing roller 22 is driven to rotate counterclockwise; the second crushing part 3 is arranged below the first crushing part 2, and the second crushing part 3 includes a first gr...

Embodiment 2

[0041] Such as Figure 8-10 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment discloses a shock absorbing component 6 for supporting the casing, specifically: the shock absorbing component 6 includes a frame body 61, a sleeve 62, a strut 63 and buffer 64, the frame body 61 is a metal frame, the frame body 61 is connected with the outer wall of the casing 1, the sleeve 62 is a metal tube, the upper end of the sleeve 62 is connected to the machine The shell 1 is connected, the strut 63 is a metal rod, the strut 63 is passed through the sleeve 61, the buffer 64 is a spring, and the buffer 64 is set on the sleeve 62 and the brace. rod 63 inside.

[0042] Further, the outer wall of the sleeve 61 is provided with a first positioning piece 611, the first positioning piece 611 is a ring of metal rings, and the first positioning piece 611 is provided with an anti-off portion 612, so that The anti-off part 612 is a metal sheet, and the anti-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com