Dropping device for grinding and polishing

A dripper and dripping technology, which is used in grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc. Stability and other issues, to achieve the effect of convenient cleaning without dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

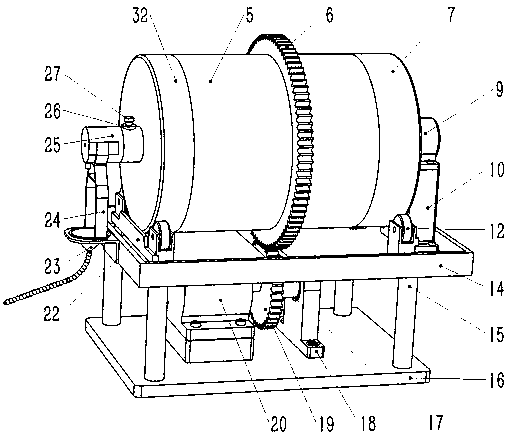

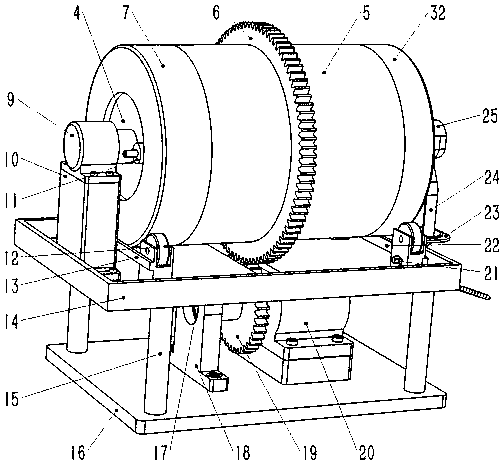

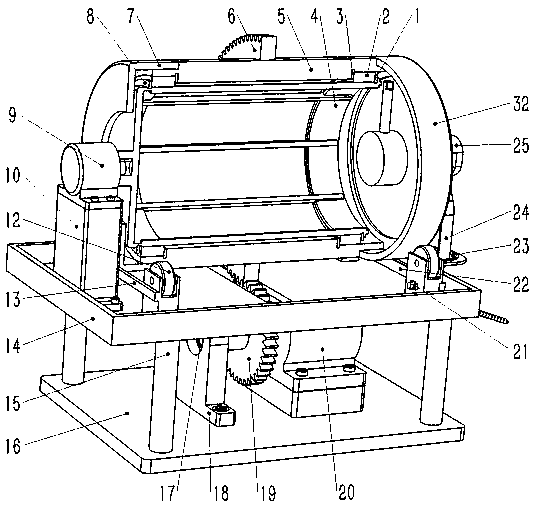

[0023] Embodiment 1: as Figure 1-5 As shown, a drop feeder for grinding and polishing, including sealing ring I1, needle bearing 2, sealing ring II3, inner drum 4, outer drum 5, large gear 6, end cover 7, positioning retaining ring I8, motor I9, Ventilation valve 11, roller 12, baffle I13, base 14, support column 15, lower bottom plate 16, bearing I17, bearing seat 18, pinion 19, motor II20, baffle lock pin 21, baffle II22, dropping funnel 23 , dripping head positioning frame 24, dripping head 25, deflector 28, positioning retaining ring Ⅱ29, sealing ring Ⅳ30, bearing Ⅱ31, feeding device 32;

[0024] A large gear 6 is provided in the middle of the outer side of the outer drum 5, and steps are provided at both ends of the inner side for installing the needle roller bearing 2. The end cover 7 and the feeding device 32 are installed on both sides of the outer drum 5; the inner drum 4 is inserted into the outer drum 5 Inside, the inner drum 4 is evenly provided with stirring rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com