Laser cutting machine splicing bed body and splicing method

A technology of laser cutting machine and bed, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of not exceeding, the laser cutting machine cannot meet the processing requirements, etc., to achieve easy access and increase the overall connection strength , the effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

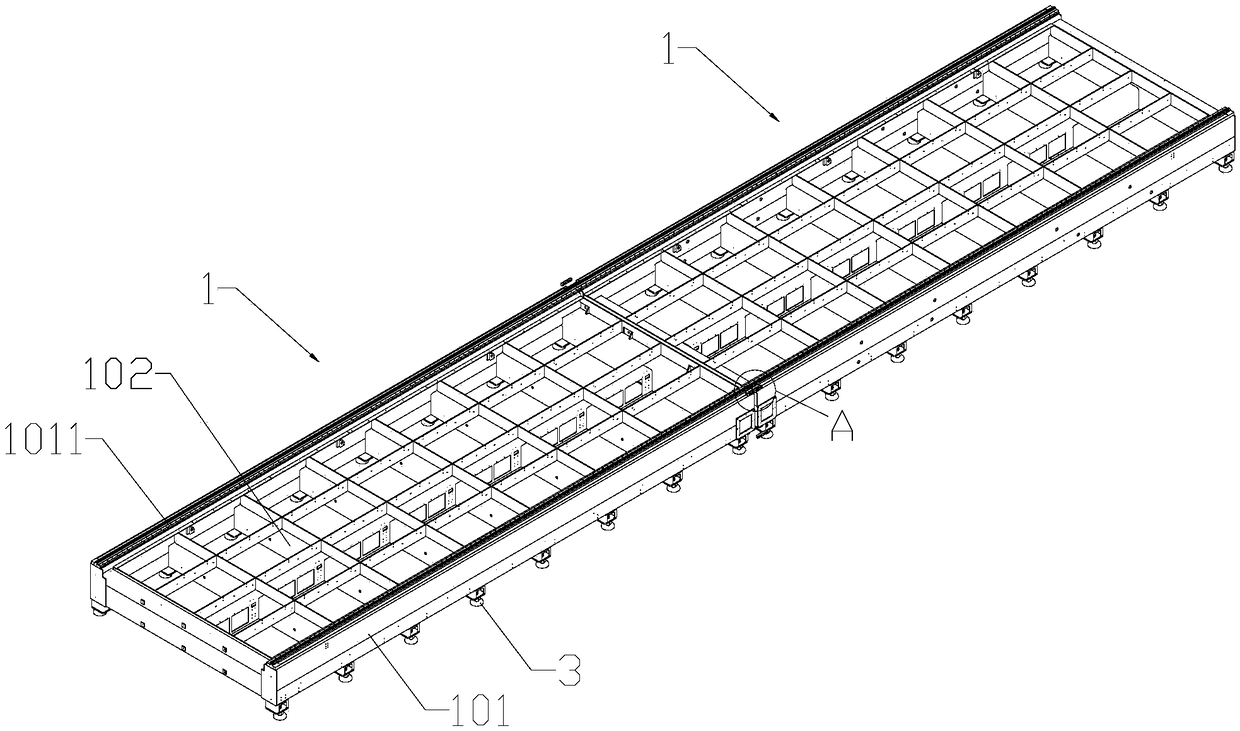

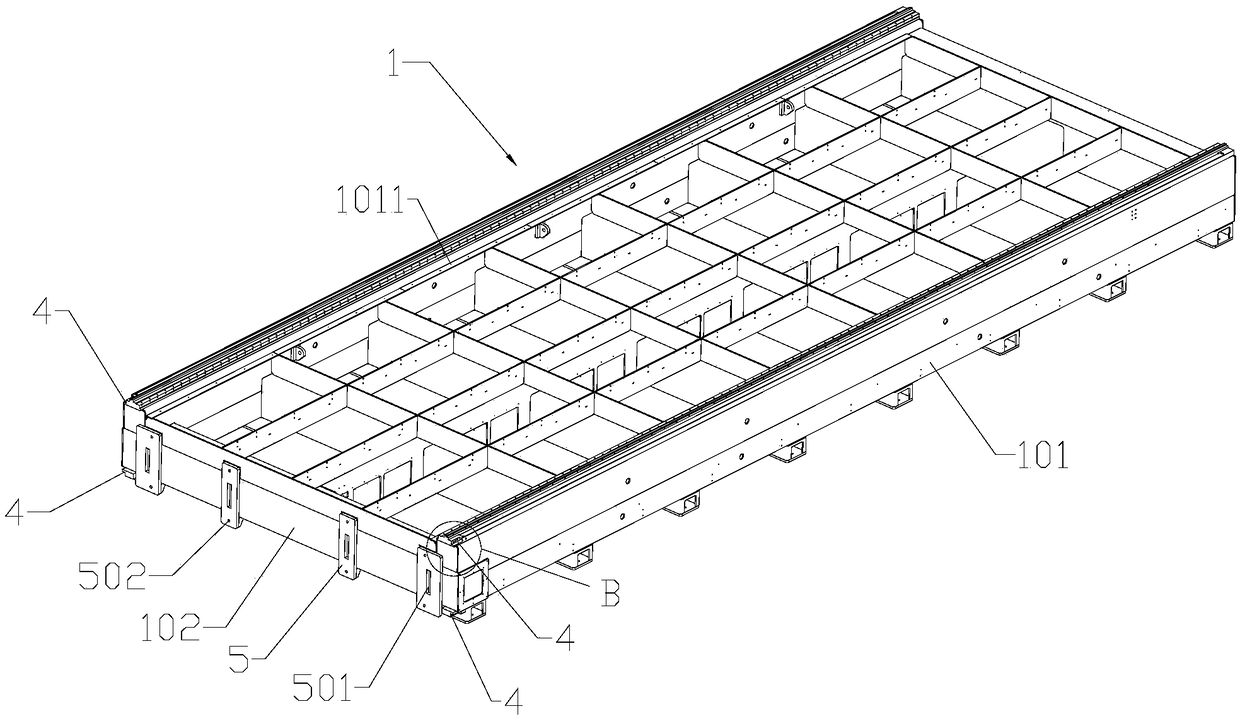

[0060] refer to figure 1 , this embodiment discloses a spliced bed of a laser cutting machine, comprising at least two single bed units 1 and a splicing block 2 connecting adjacent single bed units 1, the single bed unit 1 includes two parallel horizontal The bottom beam 101 and a plurality of longitudinal beams 102 arranged between the two horizontal bottom beams 101, the longitudinal beams 102 and the horizontal bottom beams 101 are connected by welding. 3. Set a plurality of them and evenly distribute them on the bottom of the transverse bottom beam 101 along the length direction of the transverse bottom beam 101.

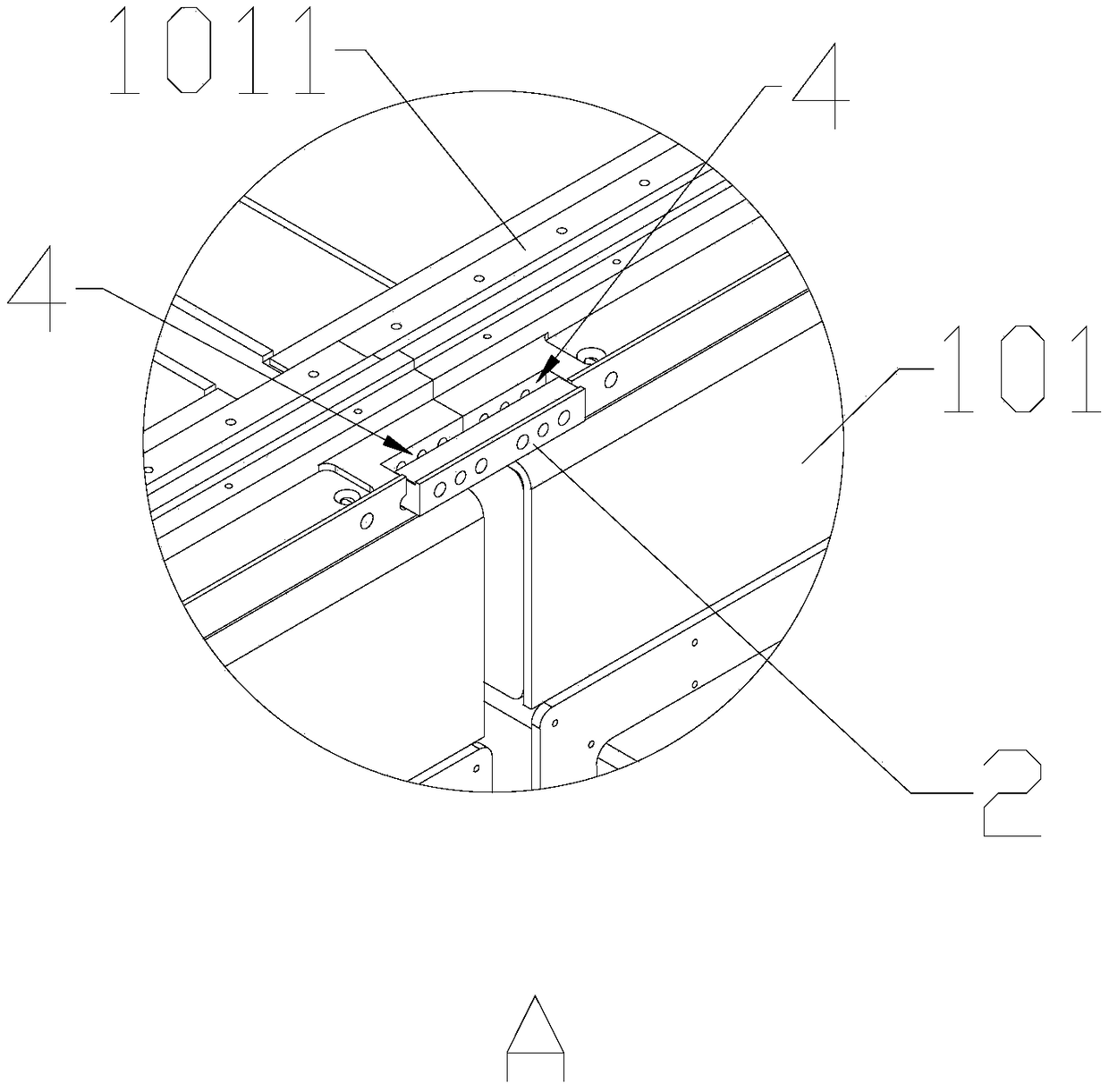

[0061] refer to figure 1 and figure 2 , the top surface of the bed body 1 is provided with a boss surface 1011 for installing the linear guide rail and the rack, the boss is located on the top surface of the two transverse bottom beams 101, the boss surface 1011 can be formed by processing the gantry milling machine, the bed body At least two splicing groo...

Embodiment 2

[0069] Based on Embodiment 1, this embodiment discloses a splicing method for splicing the bed of a laser cutting machine, including:

[0070] S1: Machining bed unit 1

[0071] Process the bed body 1 sequentially through the following processes:

[0072] S1.1: blanking welding;

[0073] S1.2: Annealing the bed body 1;

[0074] S1.3: Perform aging treatment on the bed body 1;

[0075] S1.4: Clean the surface of the bed body 1 and spray anti-rust paint;

[0076] S1.5: Rough machining, semi-finishing, and finishing of the convex table surface 1011 and splicing groove 4 by the gantry milling machine;

[0077] S1.6: Drill pin holes 4011 on the single bed body 1, process threaded holes 4012 on the single bed body with a tap, and drill through holes 502 on the splicing surface;

[0078] S2: Adjust the reference bed body

[0079] Select one bed unit 1 as the reference bed unit, and other bed units 1 as the bed units to be spliced, install the adjusting feet 3 on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com