Lamination type cavitation jet flow type pipeline cleaning machine and cleaning method thereof

A pipeline cleaning and lamination technology, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve problems such as high operating pressure, inconvenient selection of chemical cleaning liquid, and hazards in pipelines, and achieve sports balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

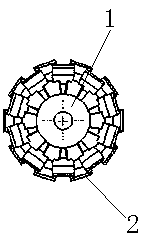

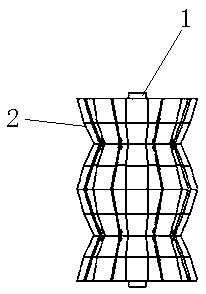

[0031] Embodiment 1: The diameter of the cleaning pipeline is 60 mm, and a reasonable cleaner is selected. The maximum diameter of the laminated blade is 56 mm, and the top of the W shape is the maximum diameter. The number of scales of the laminated blade is 8 pieces, ensuring that the distance between the maximum diameter of the laminated blade and the pipe wall is less than 5mm; put the cleaner into the pipe, and use 1MPa water flow to push the cleaner to move, so that the cleaner is in the pipe Carry out linear motion and additional rotary motion. When the pushing distance reaches 1100m, take it out and clean the next section of pipeline; pass water into the cleaned pipeline to wash the broken dirt out of the pipeline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com