Device for regulating sectional dimension of stirrup box of steel reinforcement framework machine

A technology of cross-sectional size and adjustment device, applied in the direction of online network, other household appliances, household appliances, etc., can solve the problems of single steel frame style and production process gap, and achieve the effect of simple and reasonable structure, convenient storage, and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

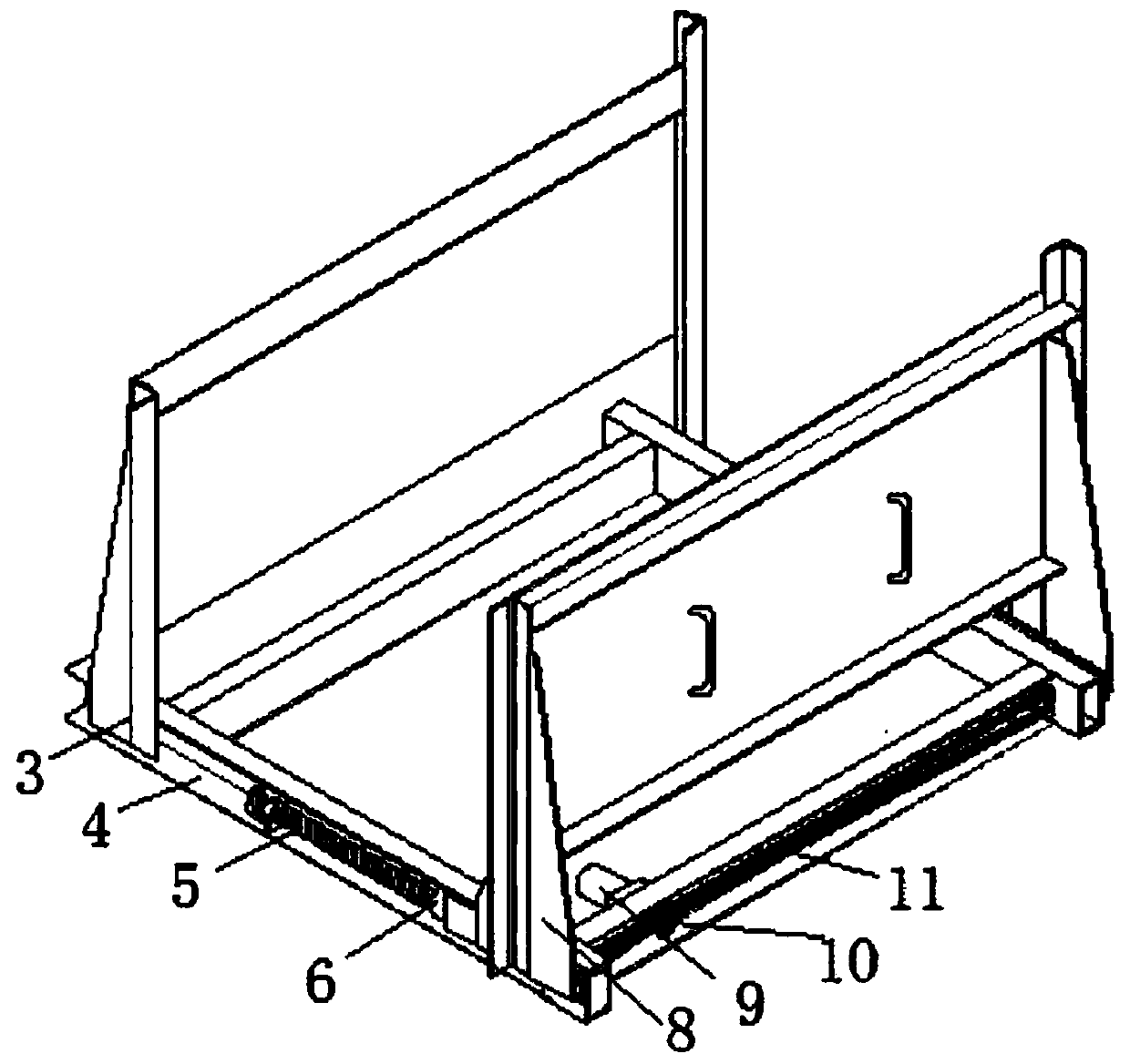

[0021] Embodiment one: if figure 2 As shown, the cross-sectional size adjustment device 2 of the stirrup box of the steel frame machine includes a screw mechanism arranged along the cross-sectional direction of the stirrup box 1 and a chain transmission mechanism for driving the screw mechanism. The two ends of the screw mechanism are fixed on the stirrup box. 1 The amplitude modulation lead screw 5 of the bottom frame 4 and the nut 6 connected to the movable frame of the stirrup box form a spiral pair, and the chain transmission mechanism is installed on the stirrup box 1 bottom frame 4 to drive the amplitude modulation screw 5 to rotate, so that the stirrup box 1 movable frame 8 moves with nut 6. Two groups of amplitude-modulating lead screws 5 of the screw mechanism are symmetrically arranged in parallel with the same thread direction, and are respectively connected with the sprockets of the chain transmission mechanism. Two nuts 6 are arranged at intervals on the same am...

Embodiment 2

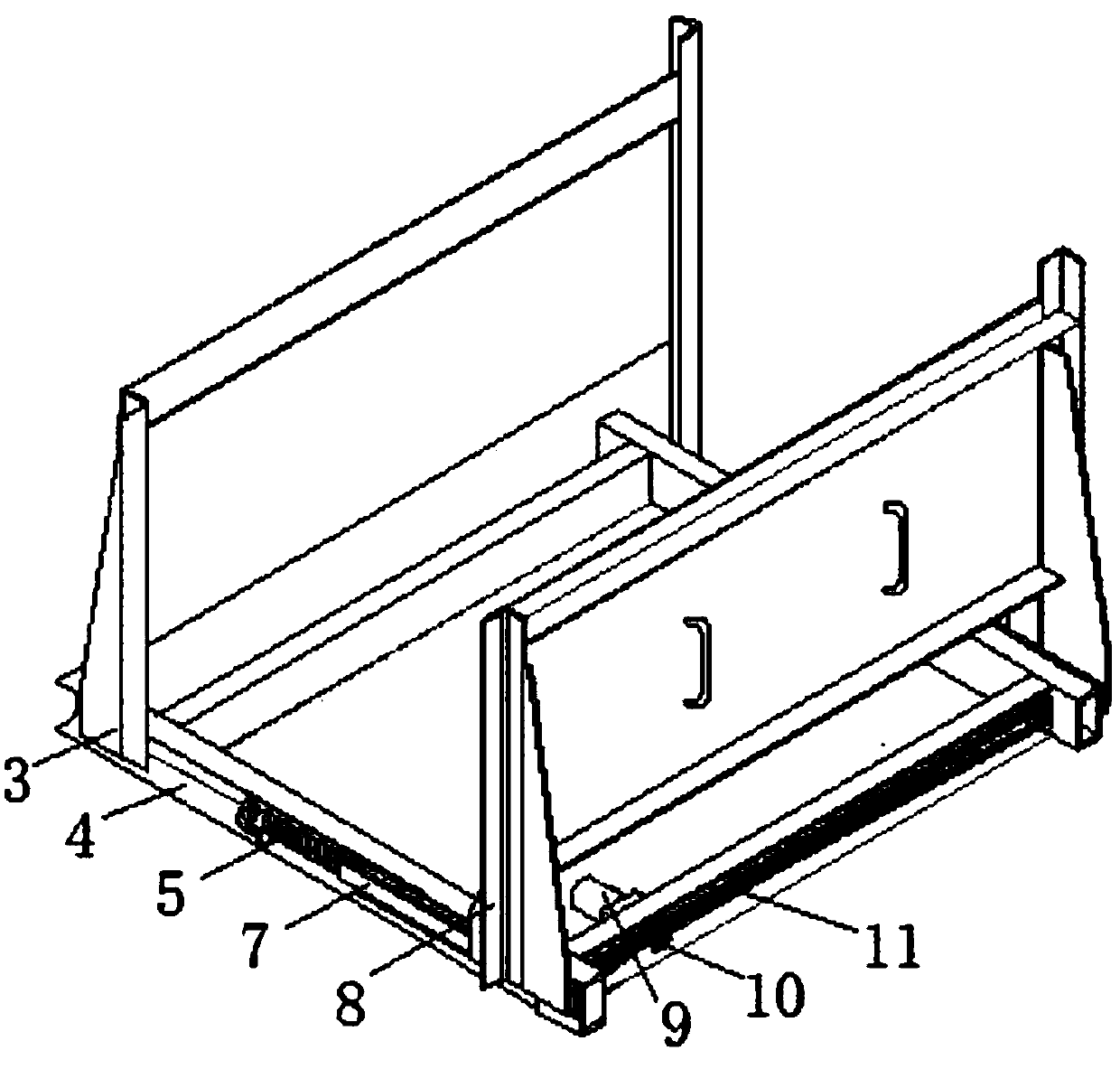

[0022] Embodiment two: if image 3 As shown, the cross-sectional size adjustment device 2 of the stirrup box of the steel frame machine also includes a screw mechanism arranged along the cross-sectional direction of the stirrup box 1 and a chain transmission mechanism for driving the screw mechanism. The two ends of the screw mechanism are fixed on the stirrup The amplitude modulation lead screw 5 of the bottom frame 4 of the box 1 and the nut connected to the movable frame 8 of the stirrup box 1 form a spiral pair, and the chain transmission mechanism is installed on the bottom frame 4 of the stirrup box 1 to drive the amplitude modulation screw 5 to rotate, so that the stirrup box 1 Movable frame 8 moves with nut. Two groups of amplitude-modulating lead screws 5 of the screw mechanism are symmetrically arranged in parallel with the same thread direction, and are respectively connected with the sprockets of the chain transmission mechanism. The difference from Embodiment 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com