Fixed-bed bioreactor with constant-flow pump/tubing system

A bioreactor, constant rate technology, applied in specific-purpose bioreactors/fermenters, methods of supporting/immobilizing microorganisms, bioreactor/fermenter combinations, etc., can solve problems such as destroying pump work

- Summary

- Abstract

- Description

- Claims

- Application Information

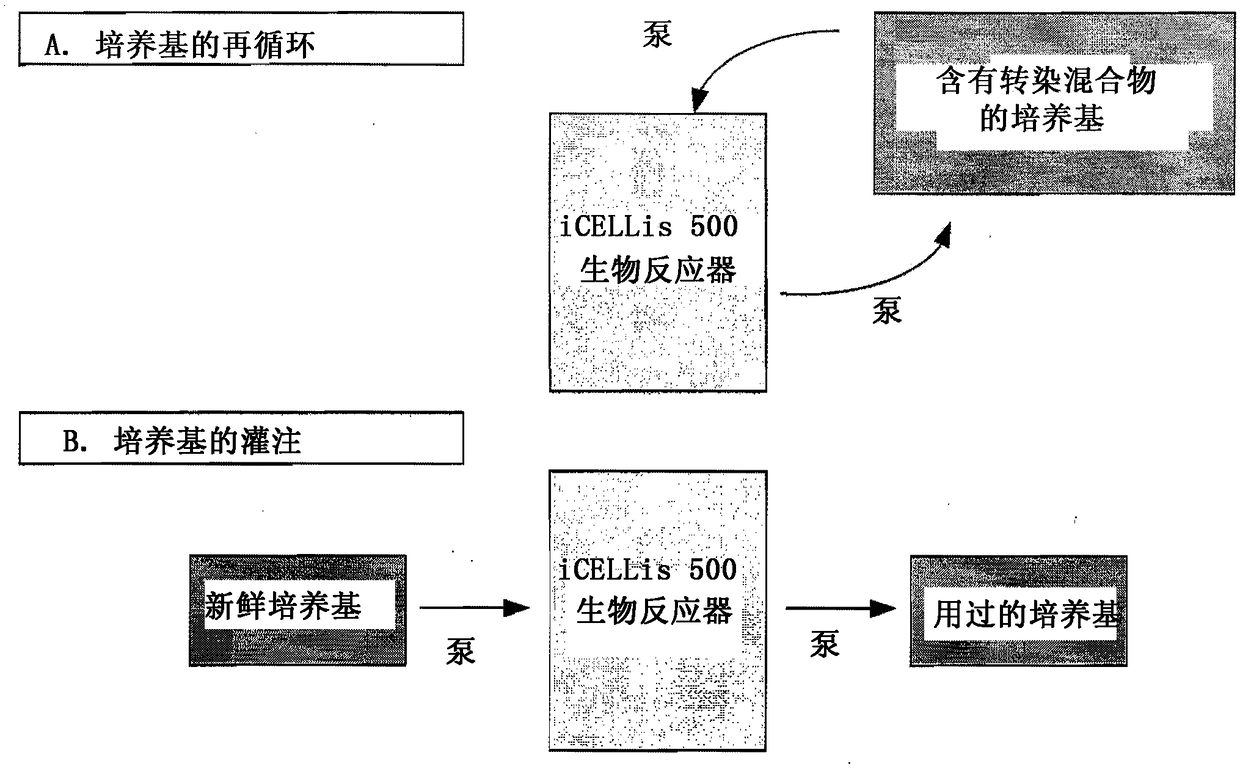

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

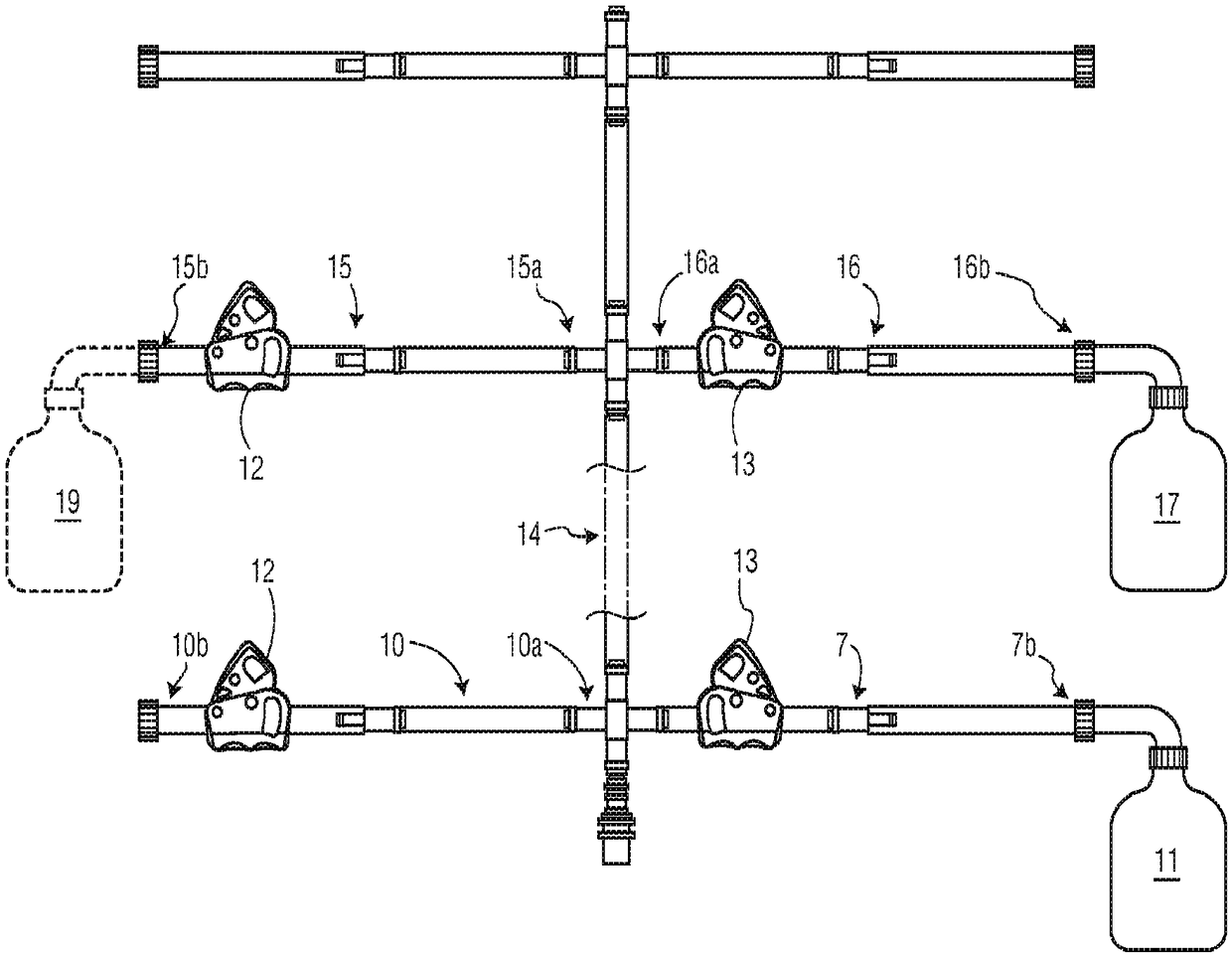

[0038] Example 3 - Unidirectional Sampling Manifold

[0039] Bioreactor sampling manifolds are used to obtain liquid samples of cell culture medium from the bioreactor vessel, for example to check pH or to measure glucose, metabolites and cellular waste products (e.g. lactate) in the medium or other substances.

[0040] We unexpectedly found that, as commercially available iCELLis TM The stock sampling manifold supplied as part of the ® is susceptible to contamination. We successfully designed a new sampling manifold for the bioreactor to eliminate the need for pumping media into and out of the bioreactor vessel into sampling bottles demand. In this way we minimize the risk of contamination by sampling.

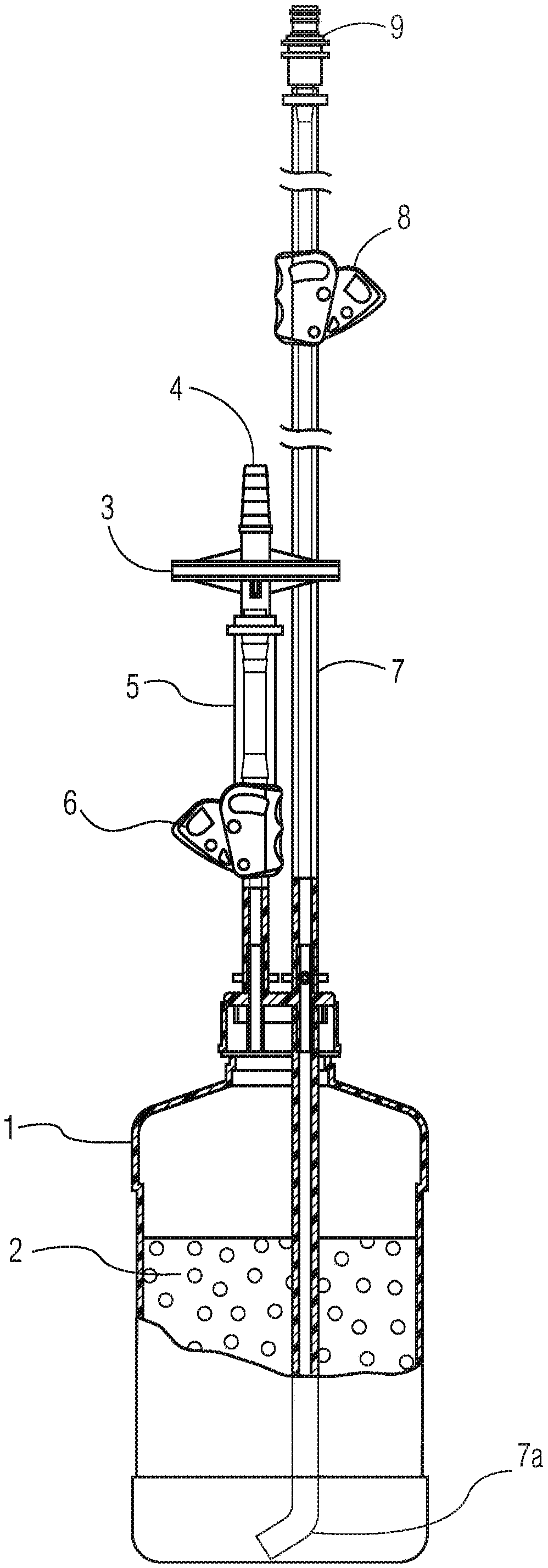

[0041] A schematic diagram of the adherent culture bioreactor is shown in figure 2 middle. The bioreactor comprises a vessel [1] containing a cell culture plate [2] to which cells adhere when cultured in an adherent mode. The container [1] contains liquid cell cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com