Contact lens bubble wrap, base member for contact lens bubbles, sealing member for contact lens bubbles, and related methods

A technology for contact lenses and packaging, which is applied in the directions of packaged objects, glasses/goggles, packaging/bundling items, etc., and can solve problems such as battery or capacitor charge dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments are described herein in the context of improved methods and improved systems for manufacturing contact lenses that include electronic components.

[0015] Those of ordinary skill in the art will realize that the following detailed description is illustrative only and is not intended to be limiting in any way. Other embodiments of the invention will be readily apparent to such skilled persons having the benefit of the invention. Reference will be made in detail to the embodiments as illustrated in the accompanying drawings. The same reference designators will be used throughout the drawings and the following detailed description to refer to the same or like parts.

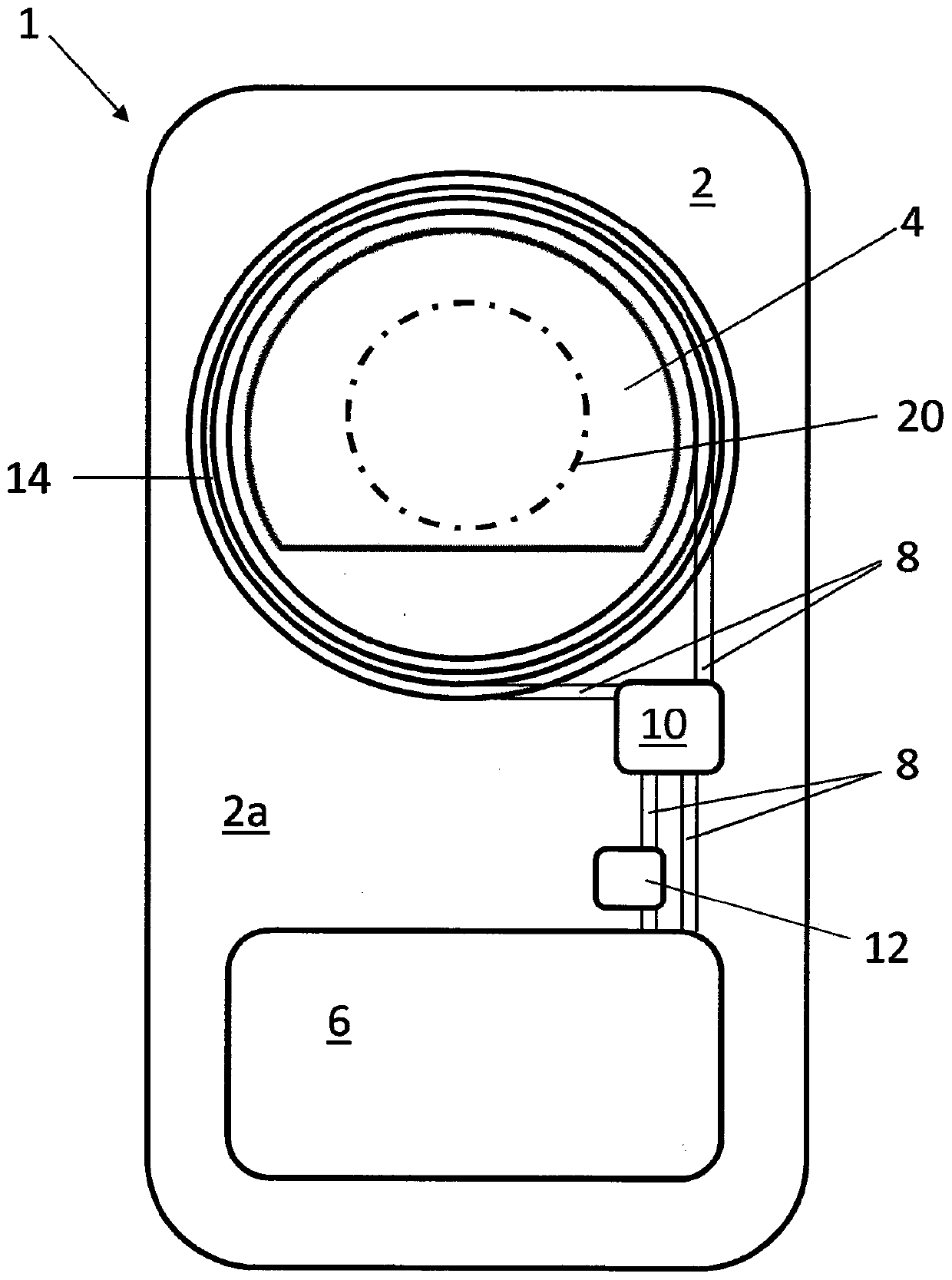

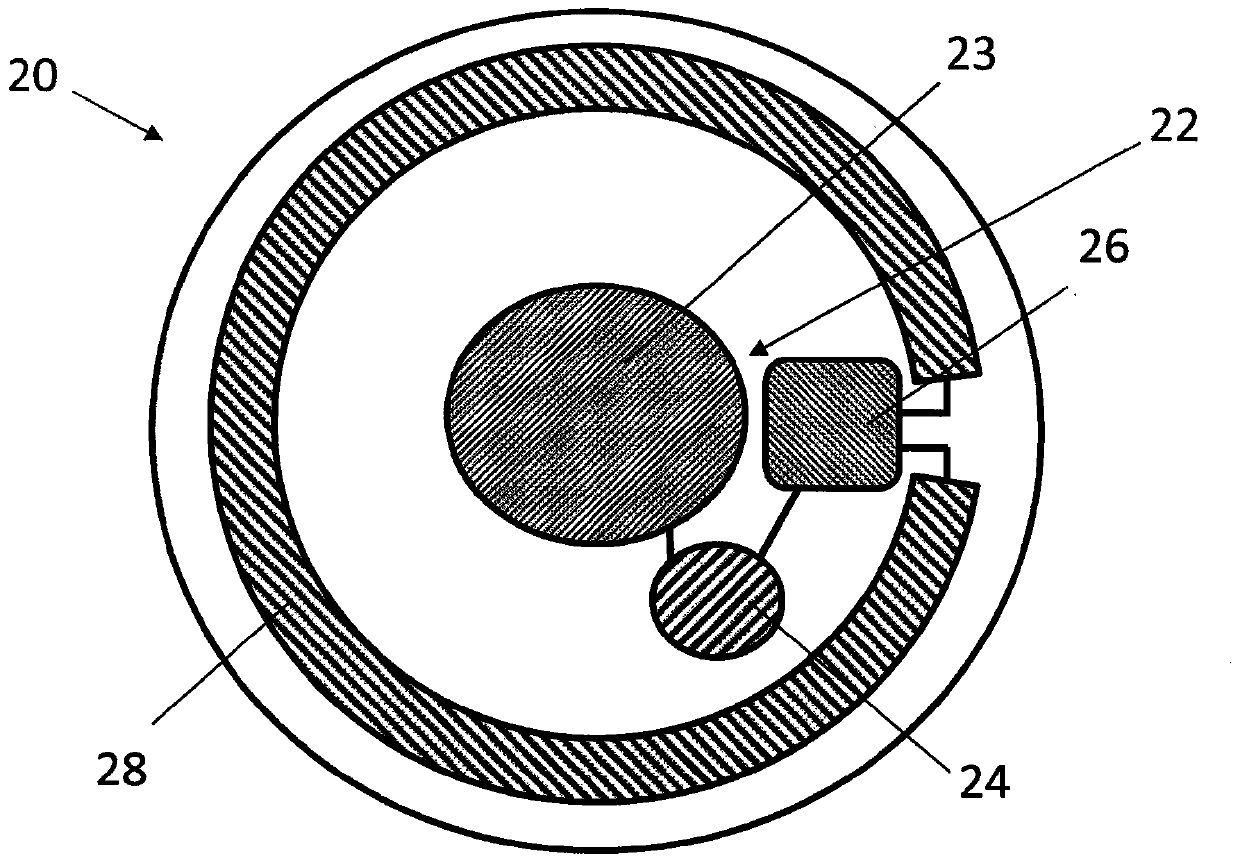

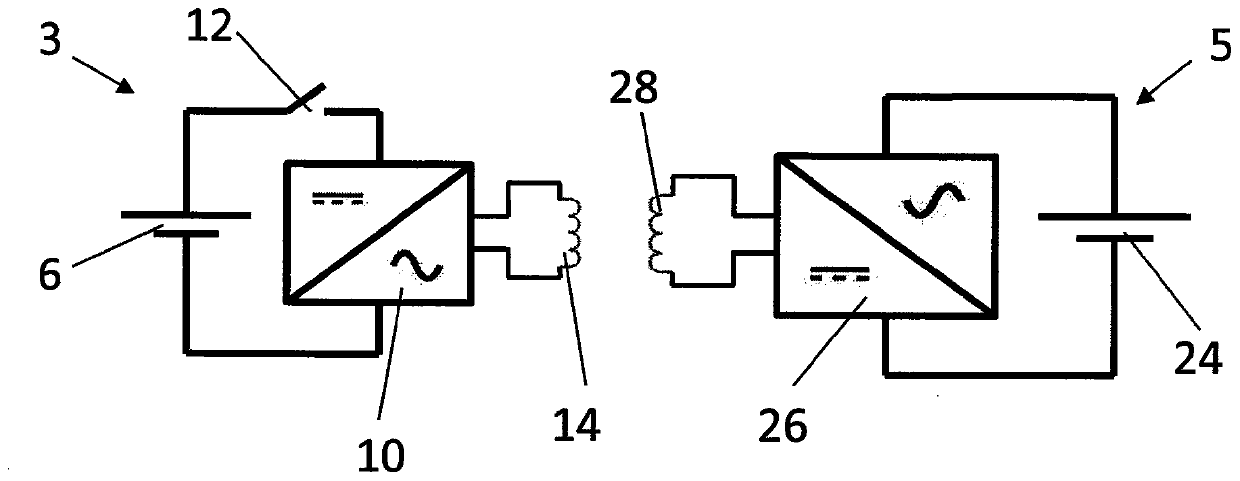

[0016] As previously stated, the first aspect of the invention relates to a contact lens blister pack. The blister pack includes a chamber for storing contact lenses. The blister pack further includes a charging circuit configured to charge an electronic device forming part of the contact lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com