A fully automatic flat conductor vertical winding machine and a winding method of flat conductor coil

A flat wire, fully automatic technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of easy deformation of the inner corner of the wire coil, no guide device, and the inability to adjust the angle at any time, etc., to achieve high volatility , good online lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

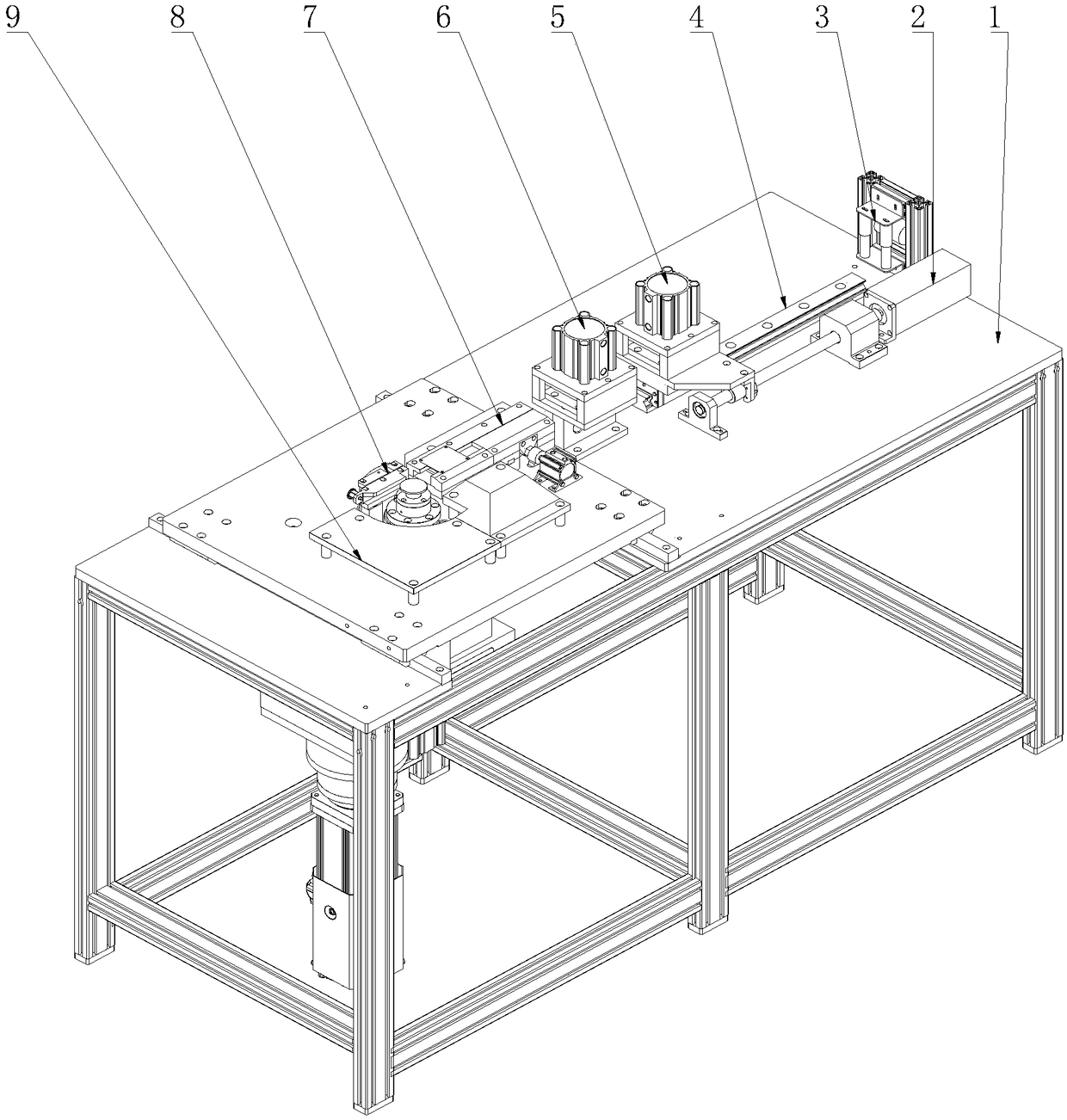

[0042] see Figure 1-11 , a fully automatic flat wire vertical winding machine, characterized in that it includes a work table 1, a linear feeding track (not shown in the figure) can be installed in front of the work table 1, and the flat wire is placed here before processing, because the feeding track Since it is a common prior art, no further description is given here.

[0043] A feeding device, a positioning device, a guiding device 7 that can realize precise guiding and positioning and online lubrication functions, a bending device 8 that prevents inner corner deformation, and an adjustable discharge platform 9 are arranged in sequence along the length of the work table 1. The work table 1 There is a PLC controller at the bottom (not shown in the figure due to the angle of view), the flat wire starts to move through the feeding device, passes through the positioning device, the guiding device 7, the bending device 8 in turn, and reaches the discharge platform 9. Make a fl...

Embodiment 2

[0056] This embodiment includes all the technical features of Embodiment 1, which also includes:

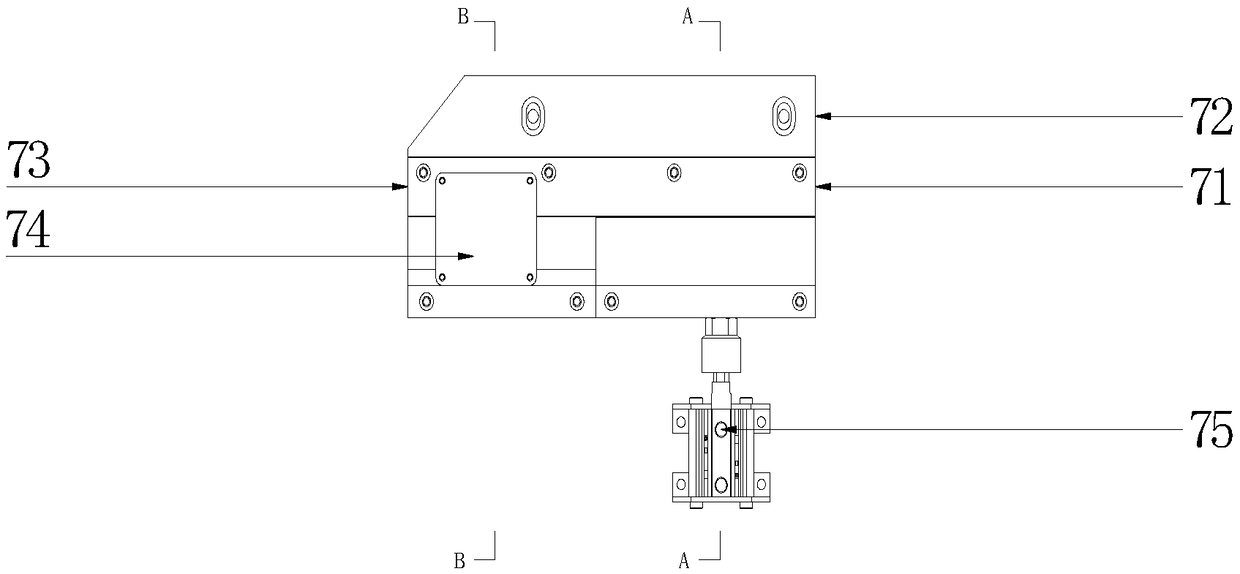

[0057] The sponge 710 is connected with a metal hose, and the metal hose is arranged at the outer shell 72 of the sponge 710, and the other end of the metal hose is connected with a pneumatic pump and an alcohol storage tank in turn, which can realize the effect of online supply of alcohol lubricating fluid.

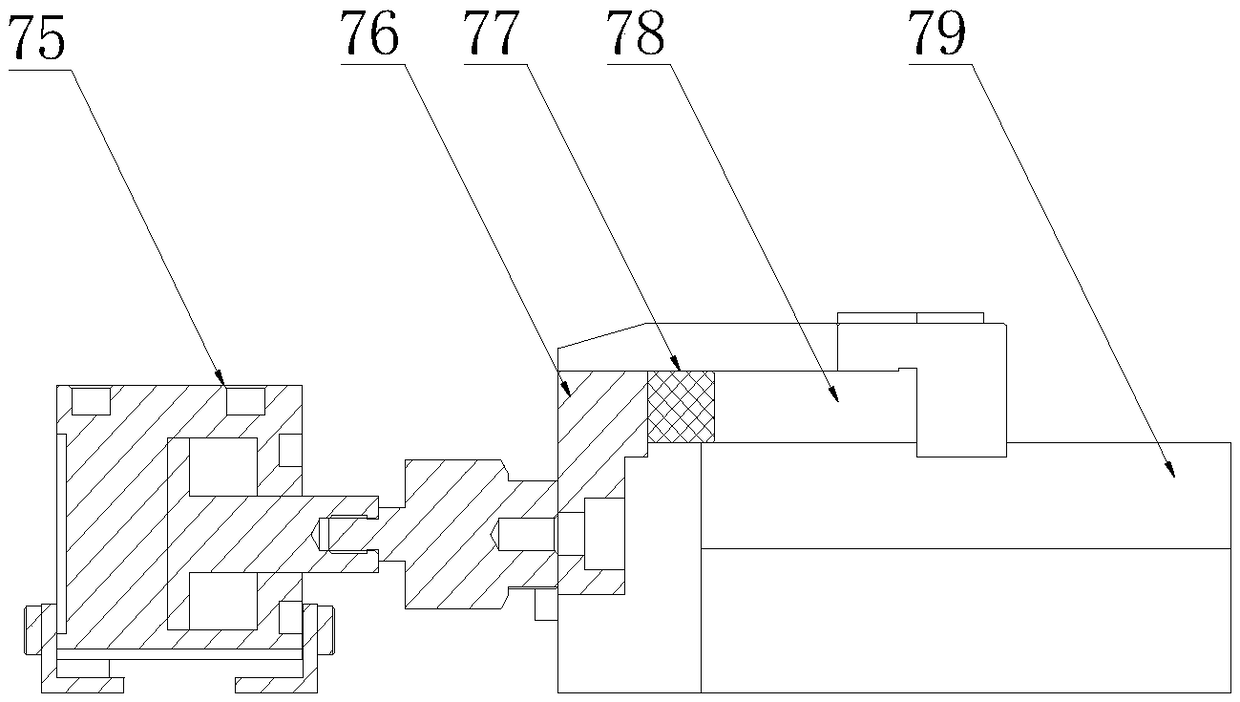

[0058] The bending device 8 has the function of preventing the inner corner of the flat conductor coil from wrinkling and deforming, and includes a rotating block 83, a rotating table 88, and an MSK070E type synchronous servo motor 2 84. The rotating block 83 is fixedly connected to the rotating table 88 side, and its inner side is provided with a The bending slot 82 through which the flat wire passes, and the bottom of the turntable 88 is connected to the servo motor 2 84 through a transmission gear.

[0059] The center of the rotary table 88 is penetrated with a molding m...

Embodiment 3

[0063] A method for winding a flat conductor coil, this method is applied to the device in any of the above embodiments, and it includes the following steps:

[0064] S1: Prepare a flat wire with a fixed size and place it on the feeding track;

[0065] S2: Draw the flat wire into the guide device 7 and the bending device 8 by clamping and moving the feeding device;

[0066] S3: After the flat wire is pulled into the guide device 7 and the bending device 8, it is first precisely positioned by the thrust guide mechanism in the guide device 7, and then fixed by the positioning device;

[0067] S4: After the flat wire is fixed, the bending device 8 starts to work. First, the flat wire is clamped by its clamping mechanism to provide a pre-pressure opposite to the deformation direction of the inner corner, and then the bending is carried out. Finally, the flat wire is discharged A flat conductor coil is formed on the platform 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com