Database-based optimization design method for water jet propulsion system

A water-jet propulsion and optimized design technology, applied in the field of amphibious vehicles and ships, can solve the problems of long design cycle, low design efficiency, and unfavorable practical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

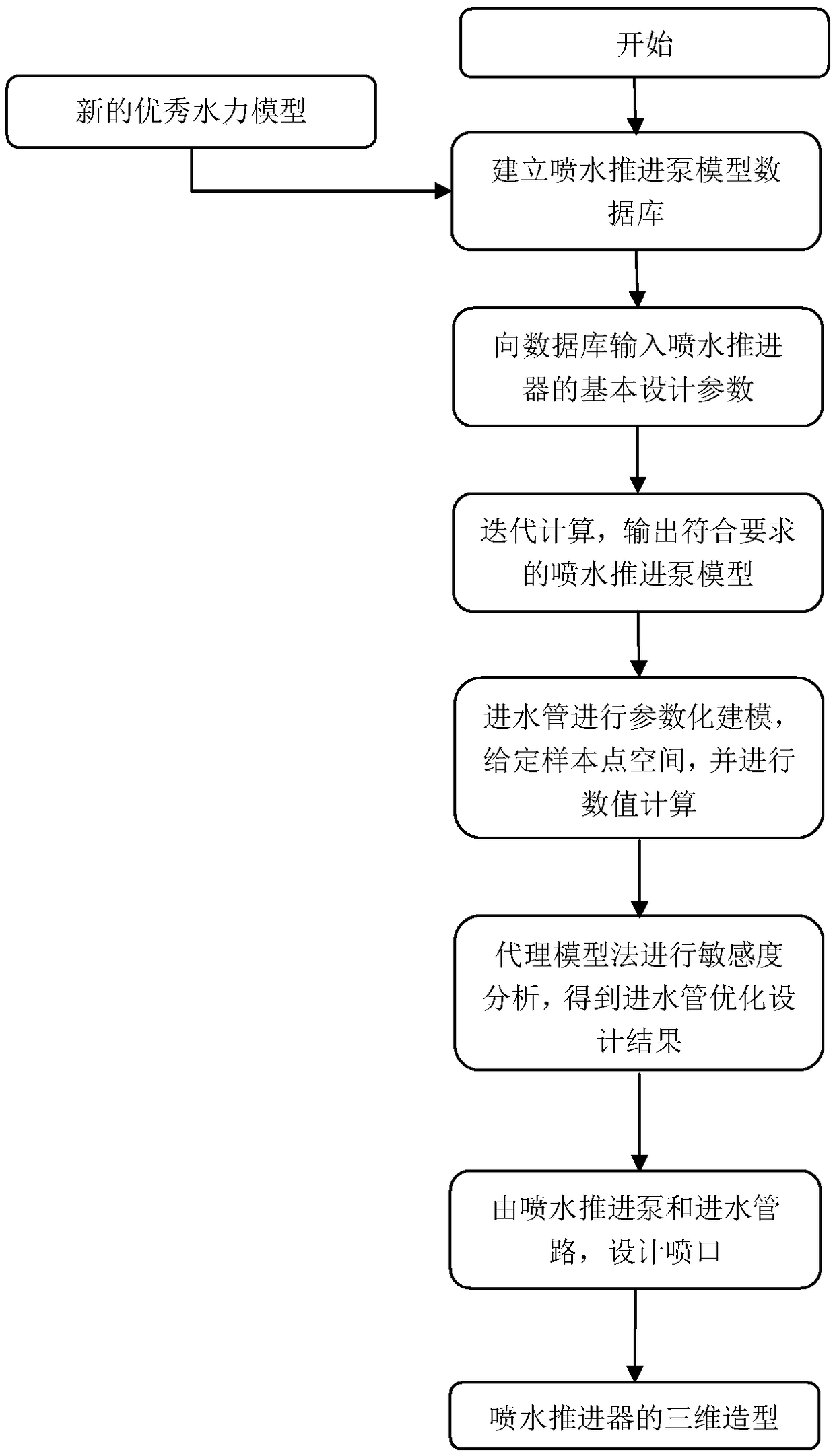

[0094] Such as figure 1 As shown, the design method of a database-based water jet propeller disclosed in this embodiment, the specific implementation steps are as follows:

[0095] Step 1: Establishment of the pump model database.

[0096] Using VB programming language, according to the pump type and its characteristic parameters, the blades corresponding to each pump type are divided into multiple cross-section layers, and the coordinate points corresponding to the blade shape of a single cross-section layer are input into the program and saved, and a single cross-section is fitted by SolidWorks The coordinate points of the blade shape generate a single cross-sectional blade shape graphic. Draw the shape graphics on all cross-sections into the same picture to form a graphics file and save it in the database. According to the characteristic parameters of different pump types, the corresponding comprehensive characteristic curves are drawn, and the comprehensive characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com