Three-dimensional detection method and device for surface form quality of paper

A technology for surface morphology and three-dimensional detection, applied in measuring devices, material analysis through optical means, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

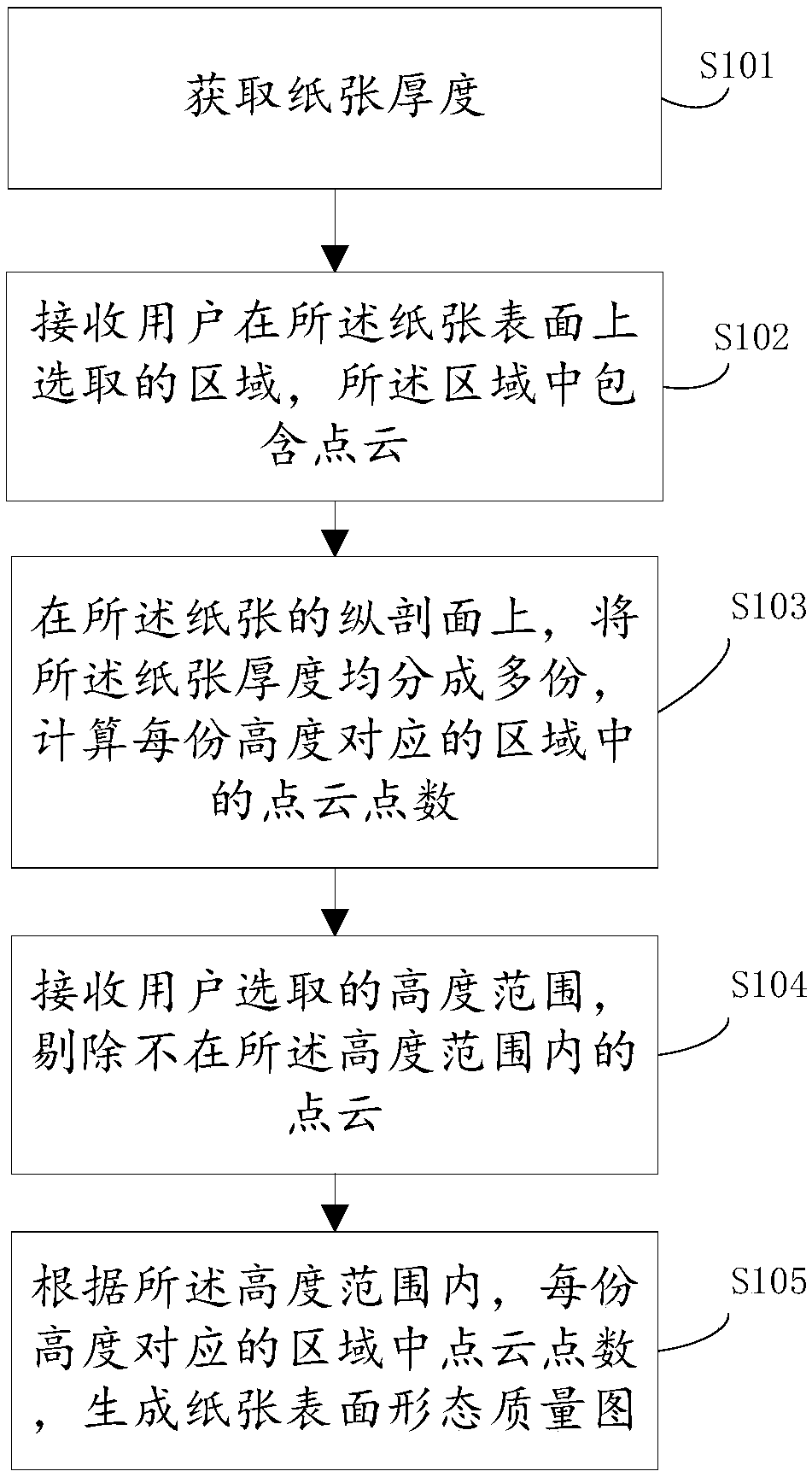

[0042] join figure 1 Shown is a flow chart of a three-dimensional detection method for paper surface morphology quality, the method specifically includes the following steps:

[0043] S101. Acquiring paper thickness;

[0044] Use 2D laser scanner, 3D translation stage, vacuum loading suction cup, etc. to obtain the paper surface thickness.

[0045] (1) Adopt the three-dimensional observation system of paper surface shape, place the paper to be tested on the three-dimensional translation platform, and connect the vacuum load sucker on the three-dimensional translation platform to the vacuum pump, turn on the vacuum pump to keep the paper flat; the system is mainly composed of two-dimensional laser It is composed of scanner, three-dimensional translation platform, vacuum loading suction cup, computer and supporting software. The two-dimensional laser scanner is arranged on the X-axis translation arm of the three-dimensional translation platform, the vacuum loading chuck is con...

Embodiment 2

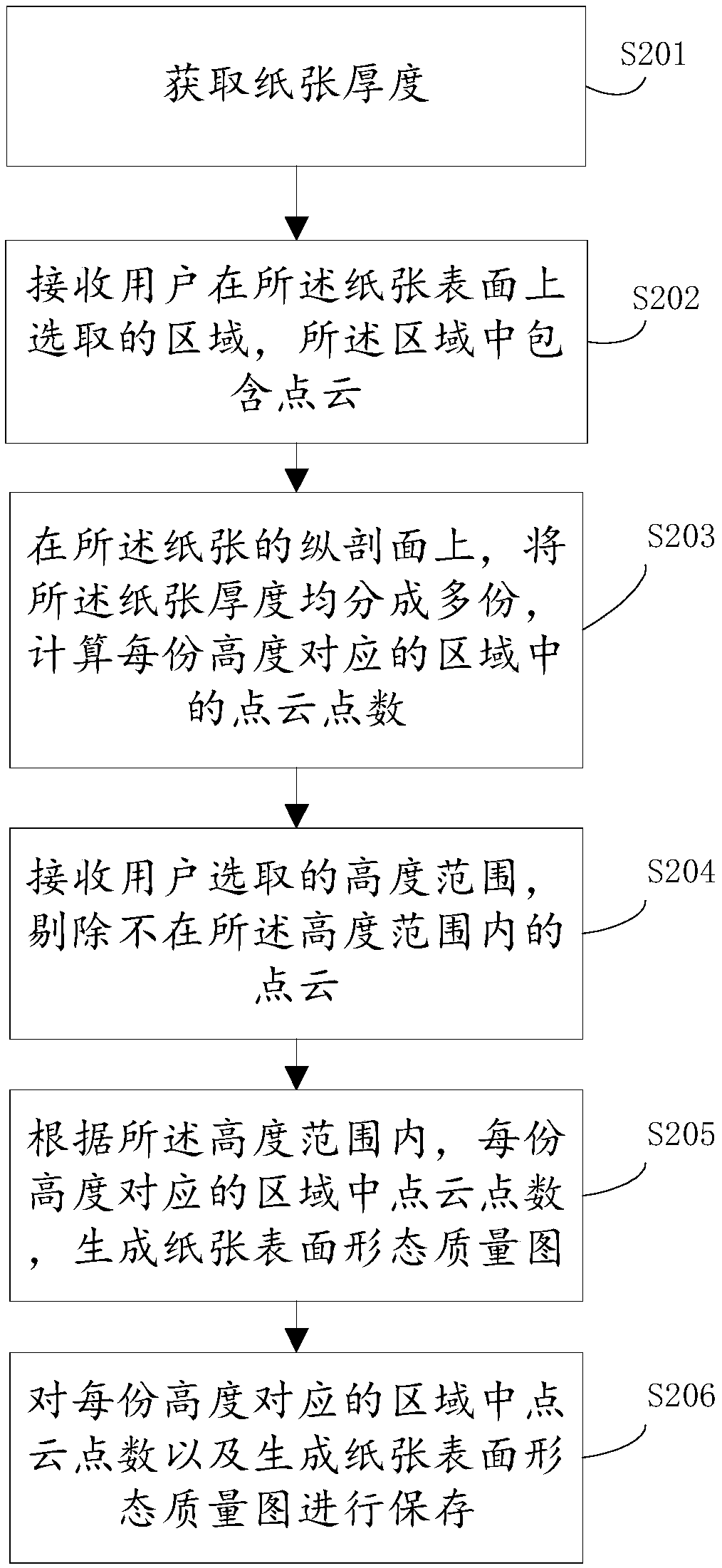

[0061] join figure 2 Shown is a flow chart of a three-dimensional detection of paper surface morphological quality, the method is implemented on the basis of the three-dimensional detection of paper surface morphological quality provided in Embodiment 1, and specifically includes the following steps:

[0062] S201. Acquiring paper thickness;

[0063] S202. Receive an area selected by the user on the surface of the paper, where the area contains a point cloud;

[0064] S203. On the longitudinal section of the paper, divide the thickness of the paper into multiple parts, and calculate the number of point cloud points in the area corresponding to the height of each part;

[0065] S204. Receive the height range selected by the user, and eliminate point clouds that are not within the height range;

[0066] S205. According to the number of point cloud points in the region corresponding to each height within the height range, generate a paper surface morphology quality map.

[00...

Embodiment 3

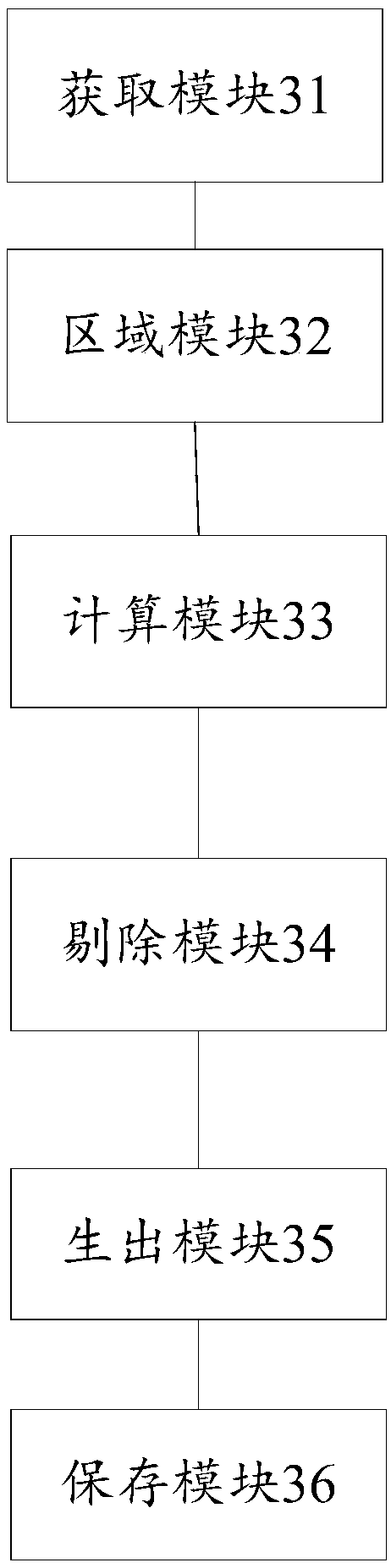

[0069] For the three-dimensional detection method of paper surface morphological quality provided in the foregoing embodiments, the embodiment of the present invention provides a device for three-dimensional detection of paper surface morphological quality, see image 3 A structural block diagram of a device for three-dimensional detection of paper surface form quality shown, the device includes the following parts:

[0070] An acquisition module 31, configured to acquire paper thickness;

[0071] The area module 32 is used to receive the area selected by the user on the surface of the paper, and the area contains a point cloud;

[0072] The calculation module 33 is used to divide the thickness of the paper into multiple parts on the longitudinal section of the paper, and calculate the number of point cloud points in the area corresponding to the height of each part;

[0073] Eliminate module 34, be used for receiving the height range that the user selects, reject the point c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com