Tensile stripping clamp for glued annular cover of automobile

A technology of stretching, peeling and sticking ring cover, which is applied in the field of testing machines to achieve the effects of reliable clamping, improved testing accuracy and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

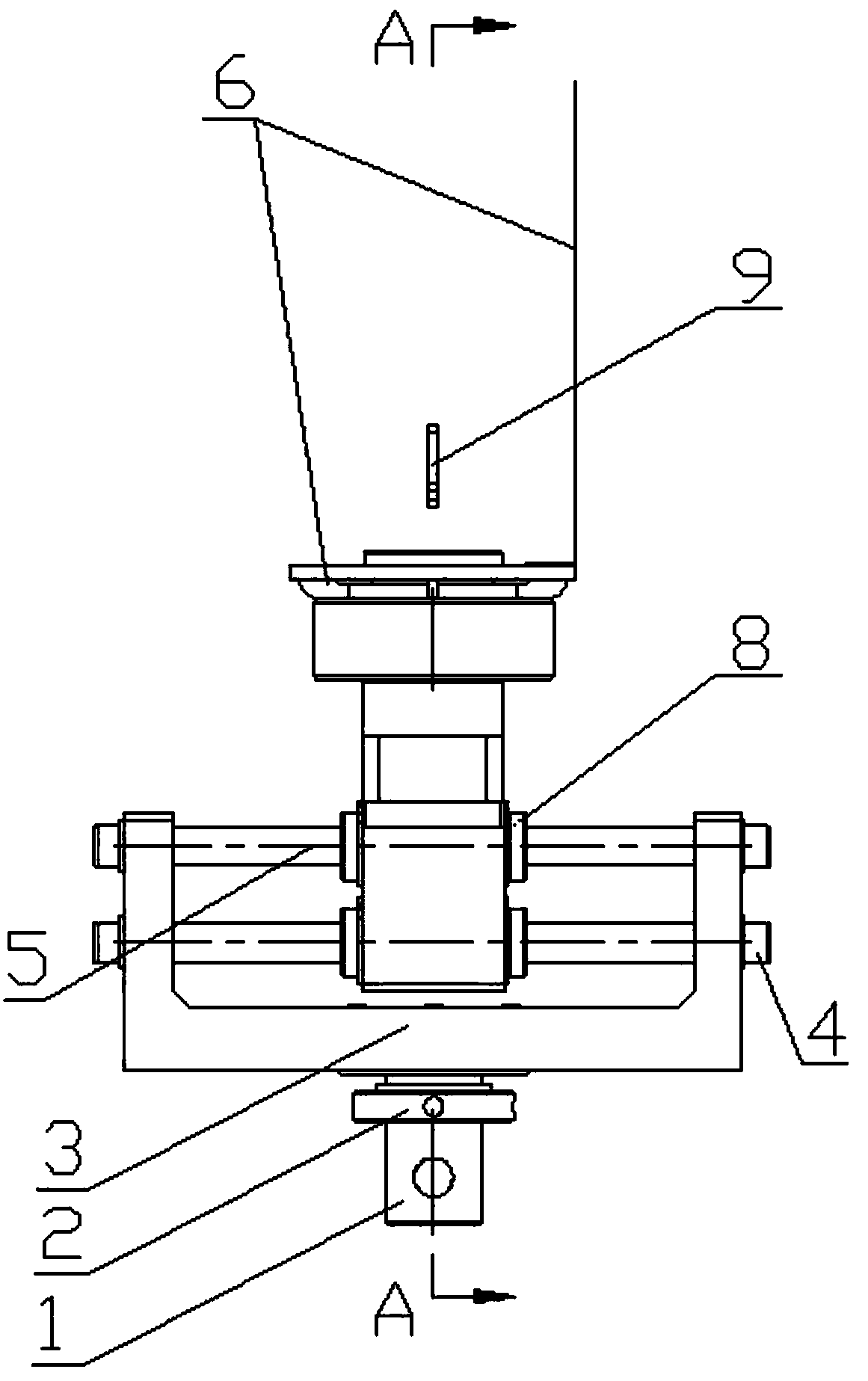

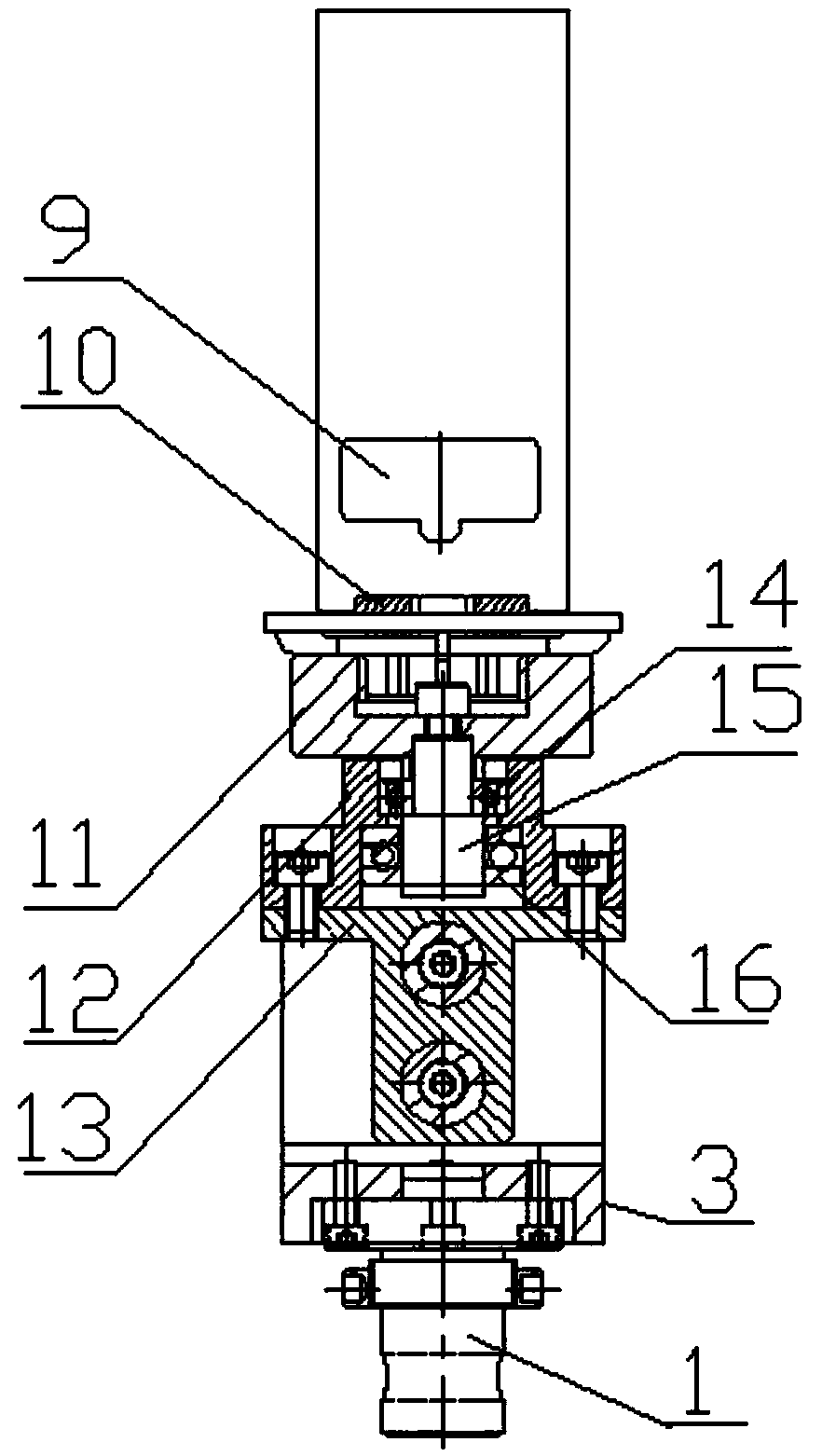

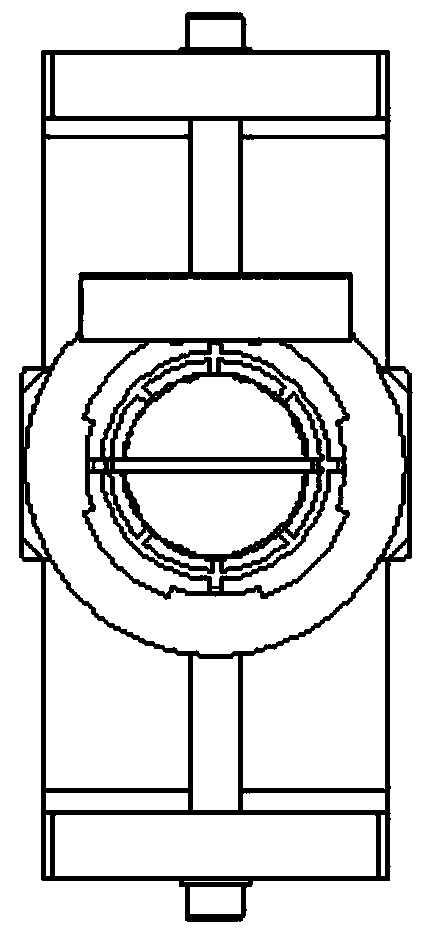

[0019] As shown in the accompanying drawings, an adhesive ring cover tensile stripping jig for automobiles includes a connector 1, a sliding bracket 3, a linear optical axis 5, a sliding support seat 13, a support seat 12, a rotating shaft 15, and a sample support seat 11. Sample pressing ring 10. The connecting head 1 is screwed to the lower part of the sliding bracket 3 . There are two linear optical axes 5, which are installed in parallel on the sliding bracket 3, and the sliding bracket 3 provides support for them. The sliding support base 13 is slidably arranged on the two linear optical axes 5 through the linear bearings 8 . The supporting base 12 is connected to the top of the sliding supporting base 13 by screws. The rotating shaft 15 is supported in the support seat 12 via a rolling bearing 14 . The sample support base 11 is fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com