A high-temperature-resistant dual-axis fiber grating vibration sensor

A vibration sensor, fiber grating technology, applied in instruments, measuring devices, using wave/particle radiation and other directions, can solve the problems of low sensitivity, inconsistent vibration directions of the main beam, and difficult to distinguish the direction of the main beam, so as to improve accuracy, improve Efficiency, Effect of Solving Temperature Drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

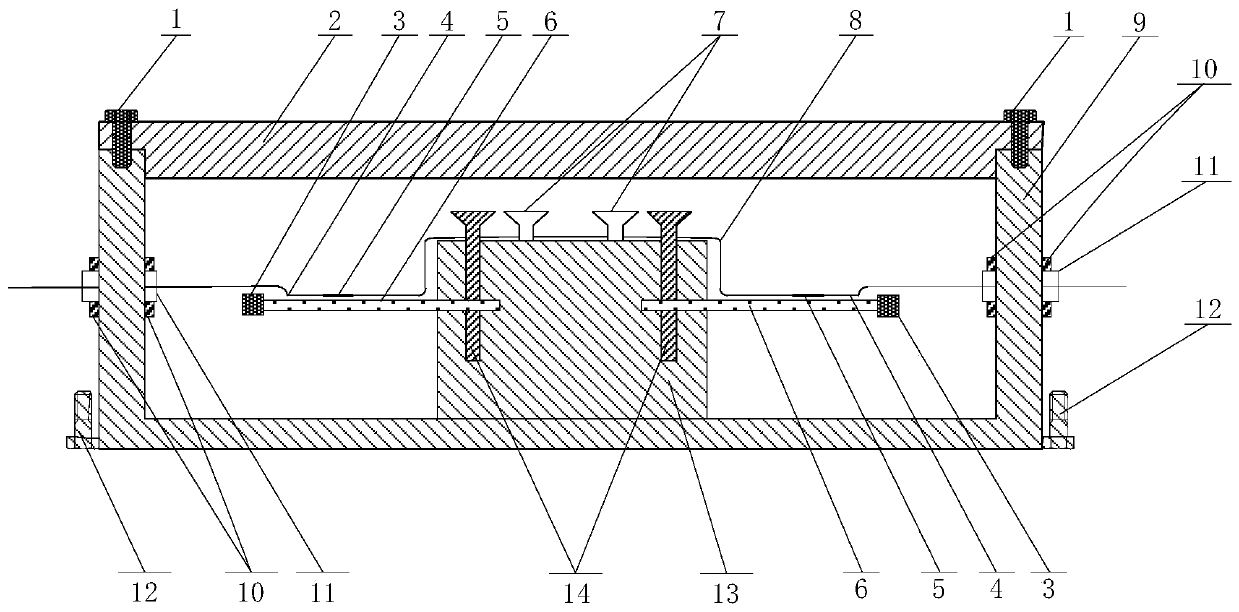

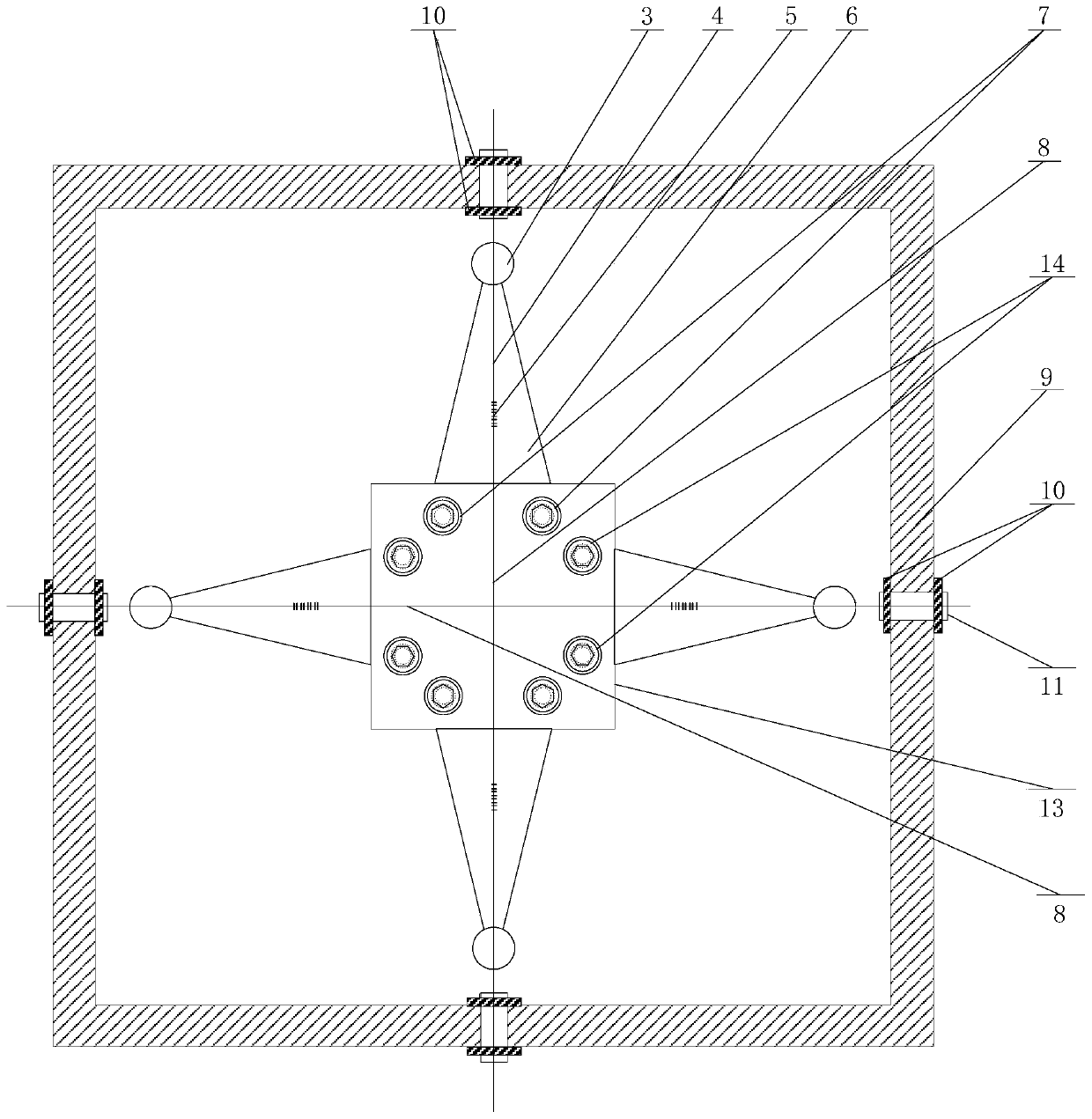

[0020] from figure 1 It can be seen that the high-temperature-resistant dual-axis fiber grating vibration sensor of this embodiment includes a sealing cover nut 1, a sealing cover 2, a mass block 3, a sensing fiber grating pigtail 4, a sensing fiber grating grating area 5, and an equal-strength cantilever Beam 6, cantilever beam fixing nut 7 with equal longitudinal strength, connecting optical fiber 8, housing 9, fiber protection sleeve fixing nut 10, fiber protection sleeve 11, sensor fixing nut 12, base 13, cantilever beam fixing nut 14 with transverse equal strength.

[0021] like figure 1 As shown, a base 13 is provided at the inner center of the housing 9 of the sensor, and the housing 9 and the base 13 are integrally stamped or welded to the center of the housing 9 . There are four equal-strength cantilever beams 6 with the same material and structural parameters on the four sides of the base 13. The spatial positions of the equal-strength cantilever beams 6 are biaxial...

Embodiment 2

[0023] In this embodiment, the central wavelength of the transverse sensing fiber grating is the same, and the central wavelength of the longitudinal sensing fiber grating is the same. The sensing fiber grating grid area 5 is written point by point using a fiber femtosecond laser, the central wavelength is 1519.99nm, and the length of the grid area is 4.7 mm, the reflectivity is 78.6%, the 3dB bandwidth is 0.375nm, and the coating layer of the sensing fiber grating is coated with polyimide.

Embodiment 3

[0025] In this embodiment, the equal-strength cantilever beam 6 is made of high-elastic alloy. The thickness of the equal-strength cantilever beam 6 is 0.5 mm, the width of the free end is 2 mm, the width of the fixed end is 15 mm, and the length is 20 mm. The radius of mass block 3 is 5mm, and the thickness is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com