Roll shaft type flattening and troweling device for panel concrete

A technology of concrete and light installations, applied in construction, building structure, construction material processing, etc., can solve problems such as low construction efficiency, impact of superficial cracks, hidden safety hazards, etc., to reduce personnel input, ensure molding quality, and speed up The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

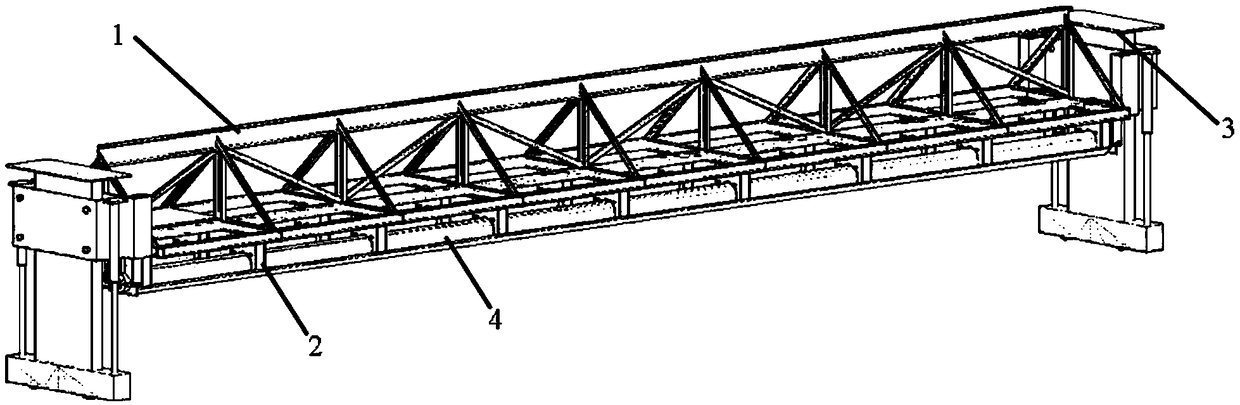

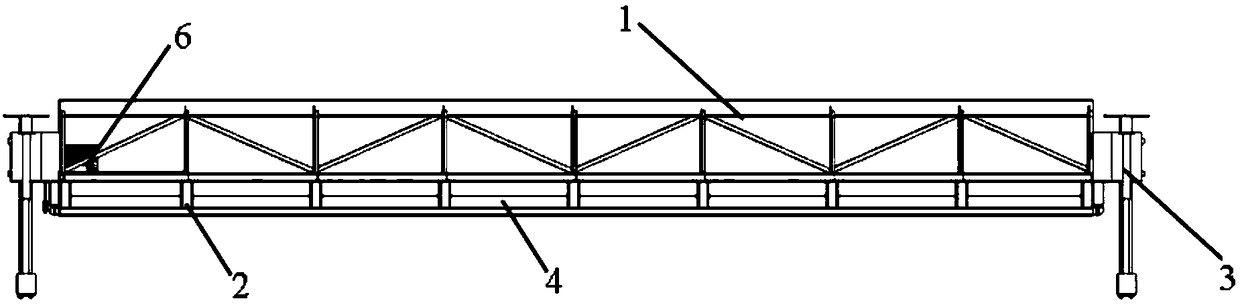

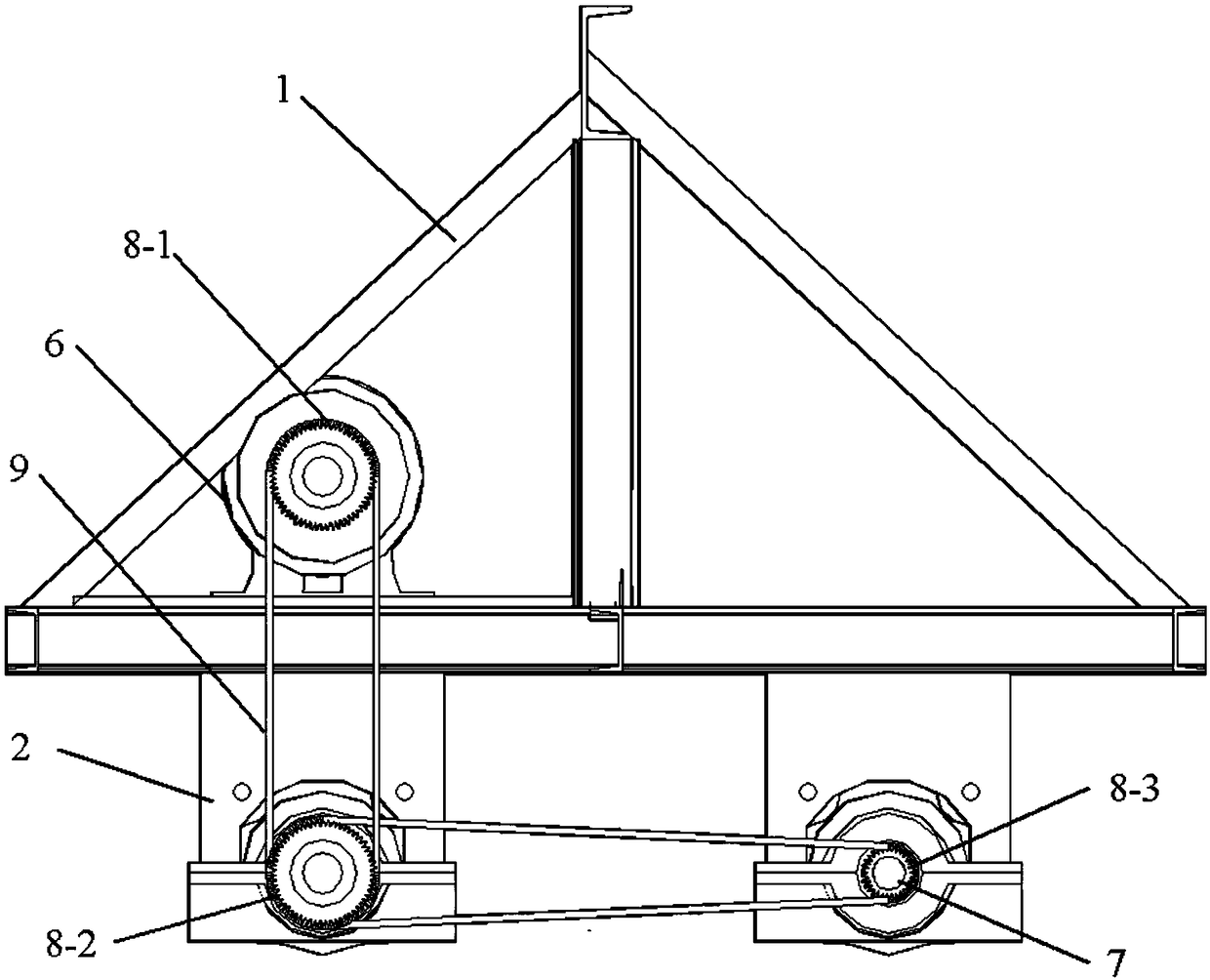

[0021] Such as Figure 1-5 As shown, a roller-type panel concrete flattening and troweling device includes a truss 1, and both ends of the truss 1 are provided with walking devices 3 with the same structure; the truss 1 can move up and down along the running device 3, and the running device 3 It can walk along the slope; the lower part of the truss 1 is provided with a roller 4, and the roller 4 is arranged on the truss 1 through the bracket 2;

[0022] The rollers 4 include a first roller arranged on the front of the truss 1 and a second roller arranged on the rear of the truss 1; one end of the first roller is provided with a first gear 8-3, and the second roller corresponds to one end A second gear 8-2 is provided; the diameter of the first gear 8-3 is smaller than that of the second gear 8-2, and the first gear 8-3 and the second gear 8-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com