Combined cofferdam structure and underwater work platform

A combined cofferdam technology, applied in foundation structure engineering, water filling, sheet pile walls, etc., can solve problems such as poor integrity of steel sheet pile cofferdam technology, small horizontal load, and failure to meet environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

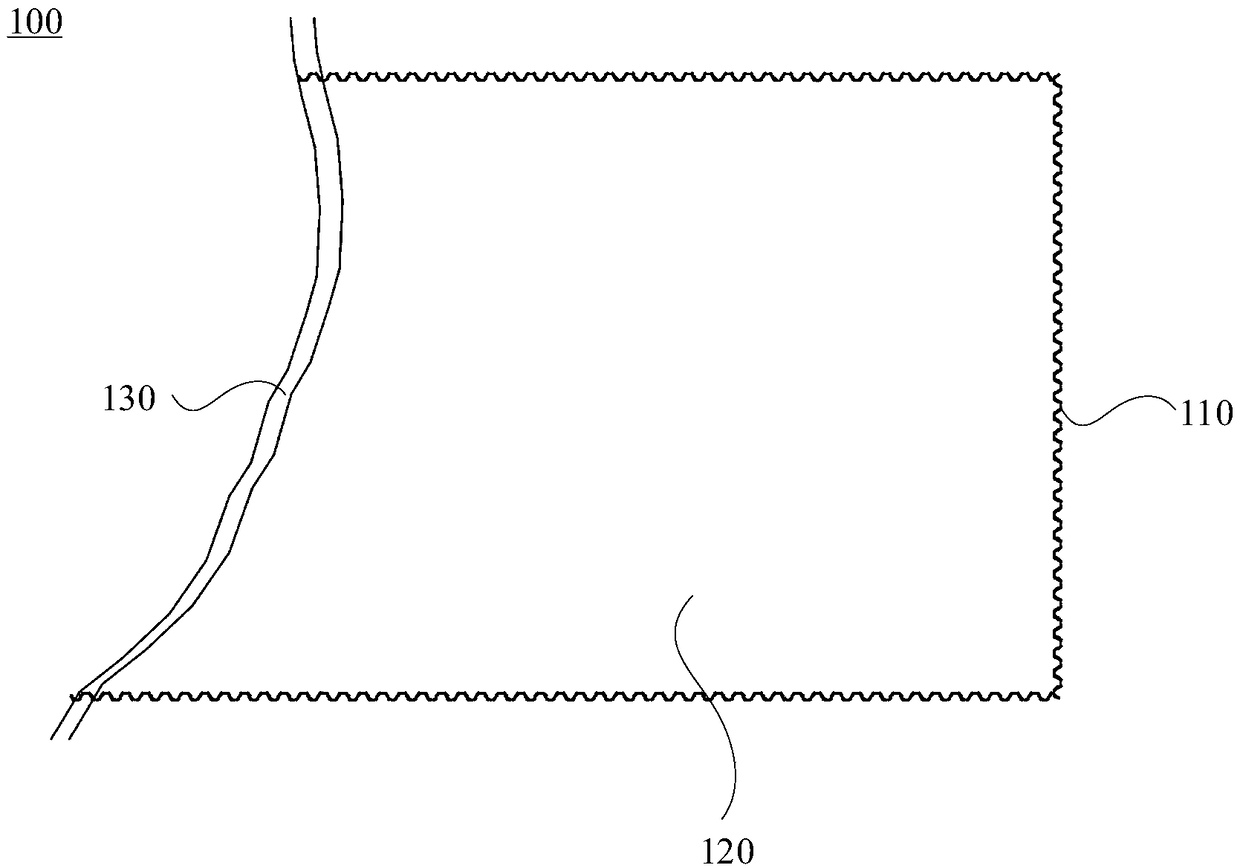

[0033] Please refer to figure 1 , the present embodiment provides a combined cofferdam structure 100, which is used for entering the waters of the embankment 130. The combined cofferdam structure 100 includes a steel sheet pile cofferdam 110 in a semi-enclosed structure, and the gap between the steel sheet pile cofferdam 110 and the embankment 130 is A closed space 120 is formed by enclosing the spaces, and the closed space 120 is filled with materials for building islands.

[0034] Island building, also known as island building core filling, refers to filling soil, sand and gravel in the area surrounded by cofferdams. For example, sandy soil can be used as the material for island construction. The soil with a lot of viscosity has a small amount of settlement when it is used as a foundation, and it is easy to compact. After compaction, it has good water stability and high strength.

[0035] Optionally, the enclosed space 120 is a quadrangular enclosed space, or may also be a ...

specific Embodiment approach

[0041] The specific embodiment of combined cofferdam structure 100 comprises the following steps:

[0042] S1: Stake out of Tsukishima sideline, such as Figure 4 As shown, according to the coordinates of the foundation design, combined with factors such as the location of the steel trestle 140 on site, determine the borderline of the island, which should exceed the design borderline of the cap by no less than 3m. Make a mark.

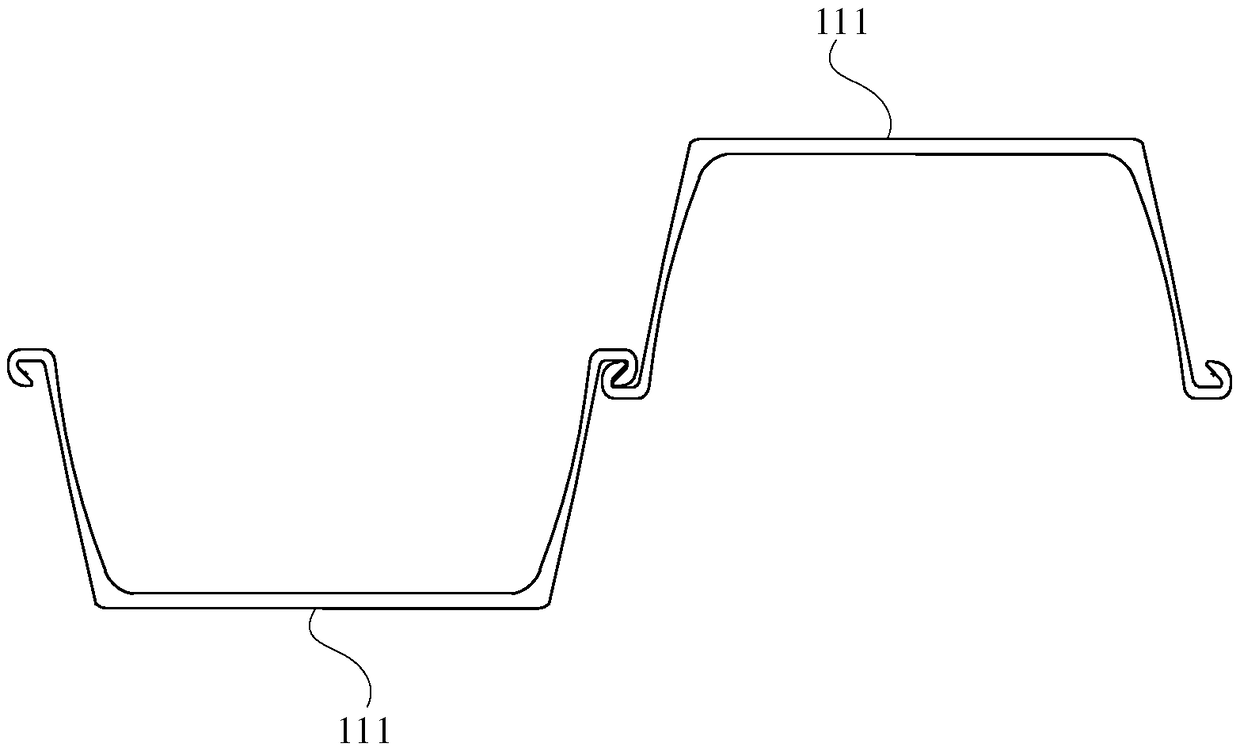

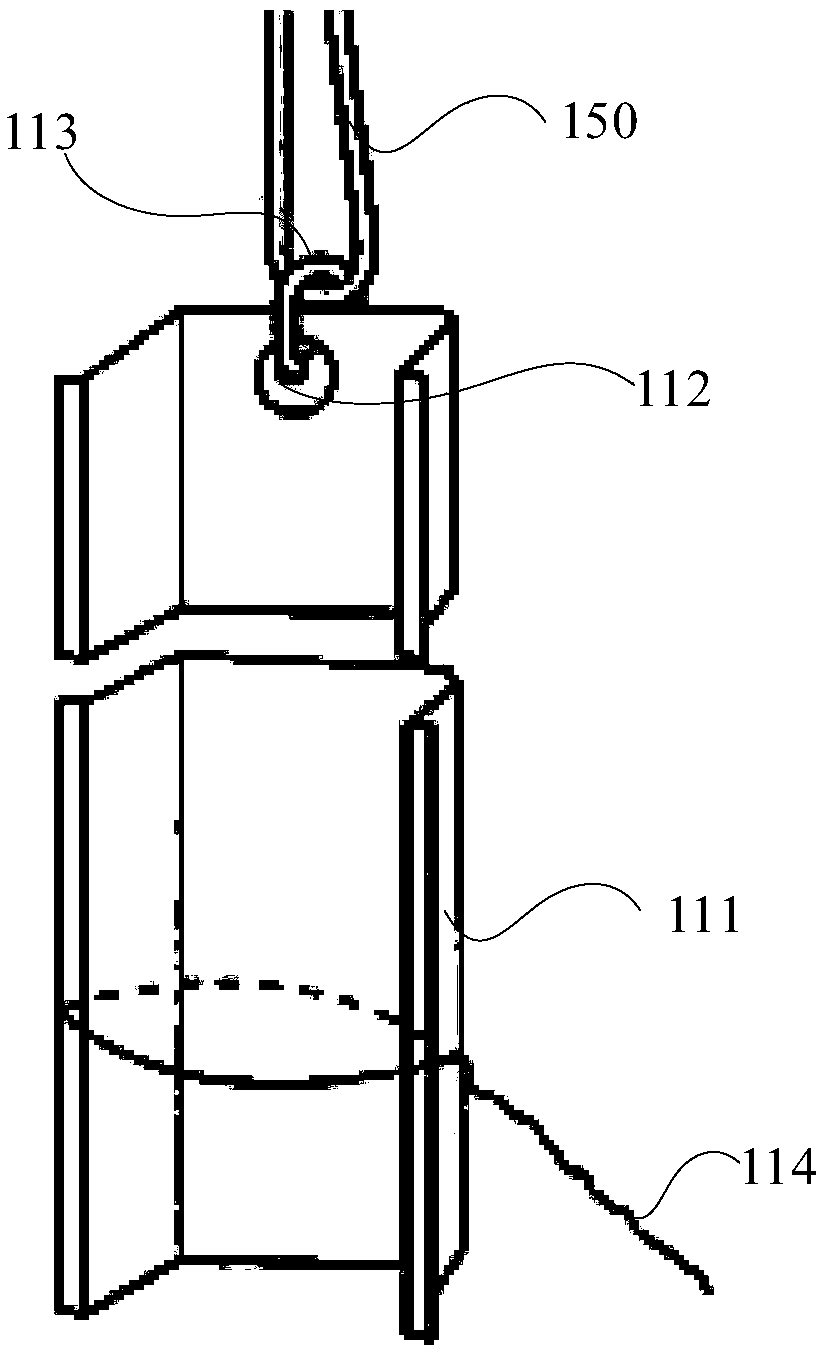

[0043] S2: Inserting and driving positioning piles. Firstly, combined with the actual hydrogeological conditions, using midas software to model, simulate the stress of the steel sheet pile 111, and obtain its theoretical depth into the soil, that is, the design elevation.

[0044] Further, mark the corresponding position of the steel sheet pile 111 pile body, that is, the design elevation, and then use the crawler crane 150 to lift the steel sheet pile 111. Preferably, a steel wire rope 114 is tied at the lower end of the steel sheet pile 111 to prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com