Construction method of pier column external wrapping weather-proof steel plate with section being straight line and circular curve combination

A construction method and a circular curve technology, which are applied in the field of bridge engineering, can solve the problems affecting the quality of poured pier and column concrete, the concrete is burned and damaged, and the quality is difficult to ensure, and achieves the effects of difficult quality assurance, high construction difficulty, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

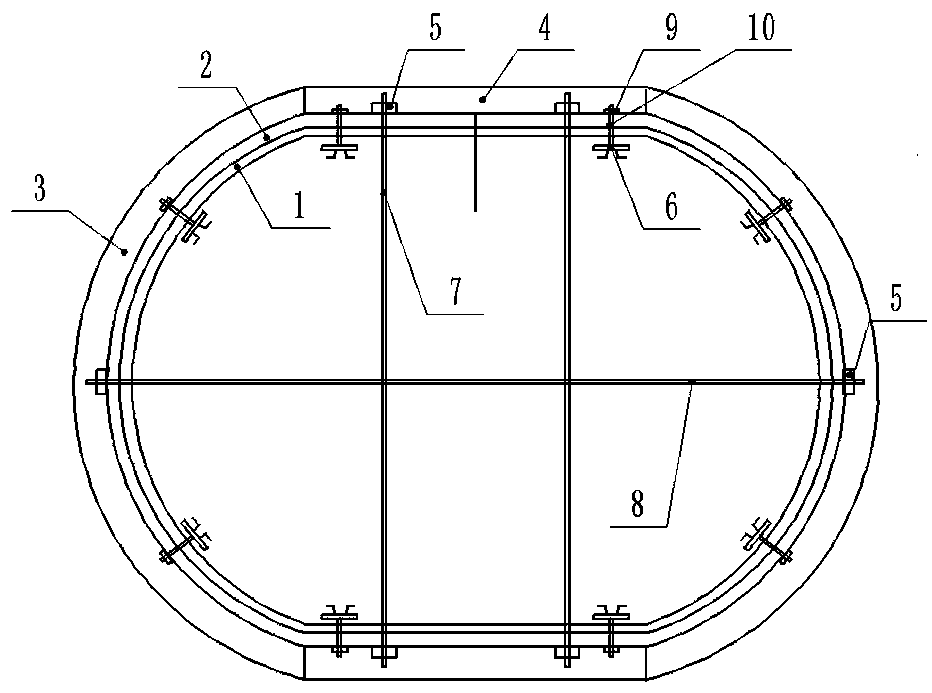

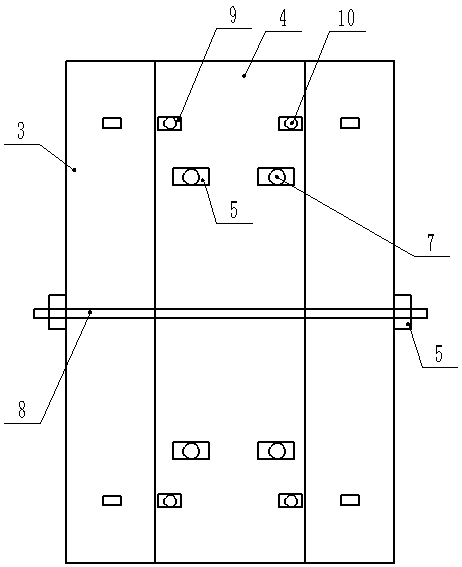

[0027] refer to figure 1 and figure 2 To further elaborate on the present invention, a construction method of a pier column with a cross-section combined with a straight line and a circular curve, which is covered with a weather-resistant steel plate, includes the following steps:

[0028] S1. Process the pier column steel formwork 2 and weather-resistant steel plate 1 according to the design drawings of the pier column to be constructed. The pier column steel formwork 2 and weather-resistant steel plate 1 are processed according to the corresponding circular curve section 3 and straight line section 4. The processed circular curve The splicing combination of segment 3 and straight segment 4 is within the allowable error range;

[0029] S2. Bind the steel bars of the pier column, and at the same time set a number of embedded plates 6 within the concrete pouring range of the pier column, and fix the embedded plates 6 with the steel bars of the pier column;

[0030] S3. Assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com