Shining waterproof zipper

A technology of waterproof zipper and waterproof coating, applied in the field of zipper, can solve the problems of zipper not having durability, exposed flashing material, cracked coating, etc., and achieve the effects of high ornamental, improved crosslinking density, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

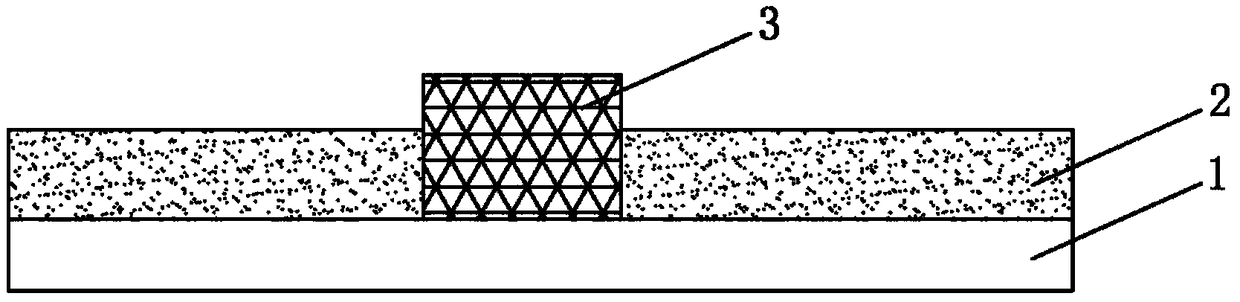

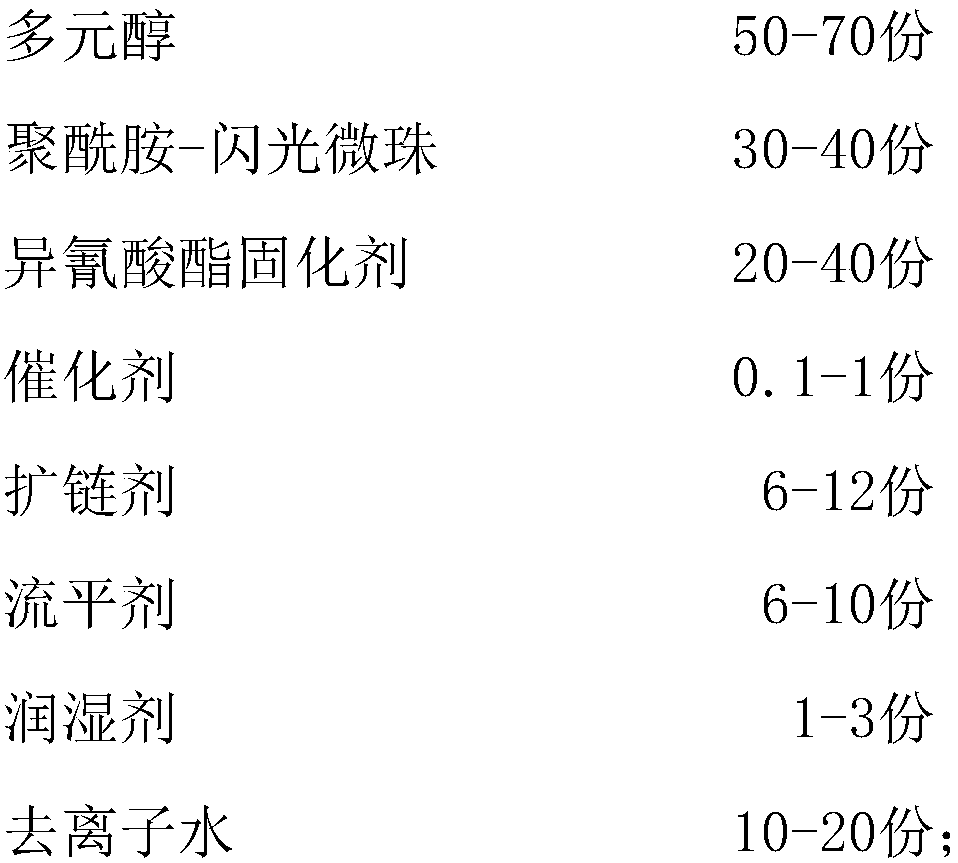

[0035] A flash waterproof zipper, comprising a cloth tape 1 and several fastener elements 3 arranged on the cloth tape 1, the cloth tape 1 is compounded with a flash waterproof coating 2, and the flash waterproof coating 2 is composed of a flash waterproof coating Prepared, the flash waterproof paint comprises the following raw materials in parts by weight:

[0036]

[0037] Wherein, the polyamide-glitter microbeads are composed of glitter microbeads and a polyacrylamide layer covering the glitter microbeads.

[0038] Wherein, the polyol is composed of polytetrahydrofuran ether diol and polycarbonate diol in a ratio of 1.5:2 by weight, the molecular weight of polytetrahydrofuran ether diol is 2500, and the hydroxyl value is 50KOH / g. The molecular weight of the alcohol is 1500, and the hydroxyl value is 45KOH / g.

[0039] Wherein, the isocyanate curing agent is composed of 4,4-diphenylmethane diisocyanate and isophorone diisocyanate in a ratio of 2:1 by weight, and the -NCO ...

Embodiment 2

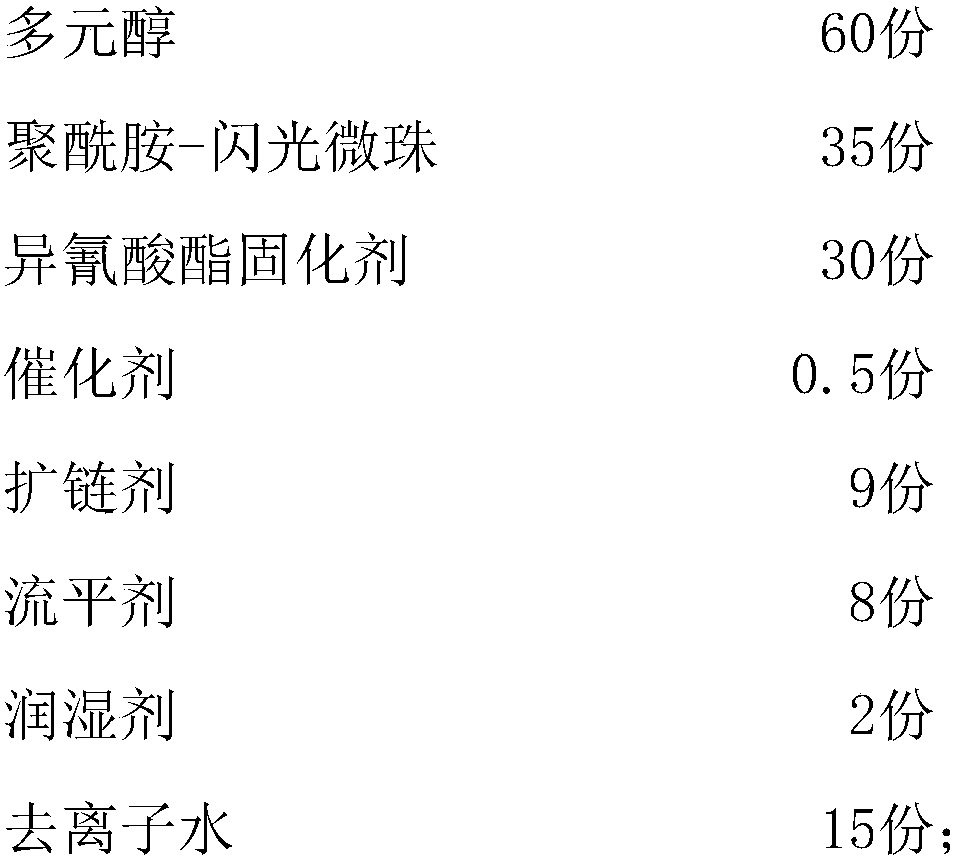

[0051] A flash waterproof zipper, comprising a cloth tape 1 and several fastener elements 3 arranged on the cloth tape 1, the cloth tape 1 is compounded with a flash waterproof coating 2, and the flash waterproof coating 2 is composed of a flash waterproof coating Prepared, the flash waterproof paint comprises the following raw materials in parts by weight:

[0052]

[0053] Wherein, the polyamide-glitter microbeads are composed of glitter microbeads and a polyacrylamide layer covering the glitter microbeads.

[0054] Wherein, the polyol is composed of polytetrahydrofuran ether diol and polycarbonate diol in a ratio of 1:1 by weight, the molecular weight of polytetrahydrofuran ether diol is 2000, and the hydroxyl value is 40KOH / g. The molecular weight of the alcohol is 1000, and the hydroxyl value is 40KOH / g.

[0055] Wherein, the isocyanate curing agent is composed of 4,4-diphenylmethane diisocyanate and isophorone diisocyanate in a ratio of 1:1 by weight, and the -NCO of...

Embodiment 3

[0067] A flash waterproof zipper, comprising a cloth tape 1 and several fastener elements 3 arranged on the cloth tape 1, the cloth tape 1 is compounded with a flash waterproof coating 2, and the flash waterproof coating 2 is composed of a flash waterproof coating Prepared, the flash waterproof paint comprises the following raw materials in parts by weight:

[0068]

[0069]

[0070] Wherein, the polyamide-glitter microbeads are composed of glitter microbeads and a polyacrylamide layer covering the glitter microbeads.

[0071] Wherein, the polyol is composed of polytetrahydrofuran ether diol and polycarbonate diol in a ratio of 2:3 by weight, the molecular weight of polytetrahydrofuran ether diol is 3000, and the hydroxyl value is 60KOH / g. The molecular weight of the alcohol is 2000, and the hydroxyl value is 50KOH / g.

[0072] Wherein, the isocyanate curing agent is composed of 4,4-diphenylmethane diisocyanate and isophorone diisocyanate in a ratio of 3:1 by weight, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com