Polyurethane flash waterproof paint for zippers and preparation method of polyurethane flash waterproof paint

A waterproof coating and polyurethane technology, applied in the field of zipper waterproof coating, can solve the problems of zipper not having durability, exposed flashing material, cracked coating, etc., and achieve the effects of high ornamental, improved stability and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

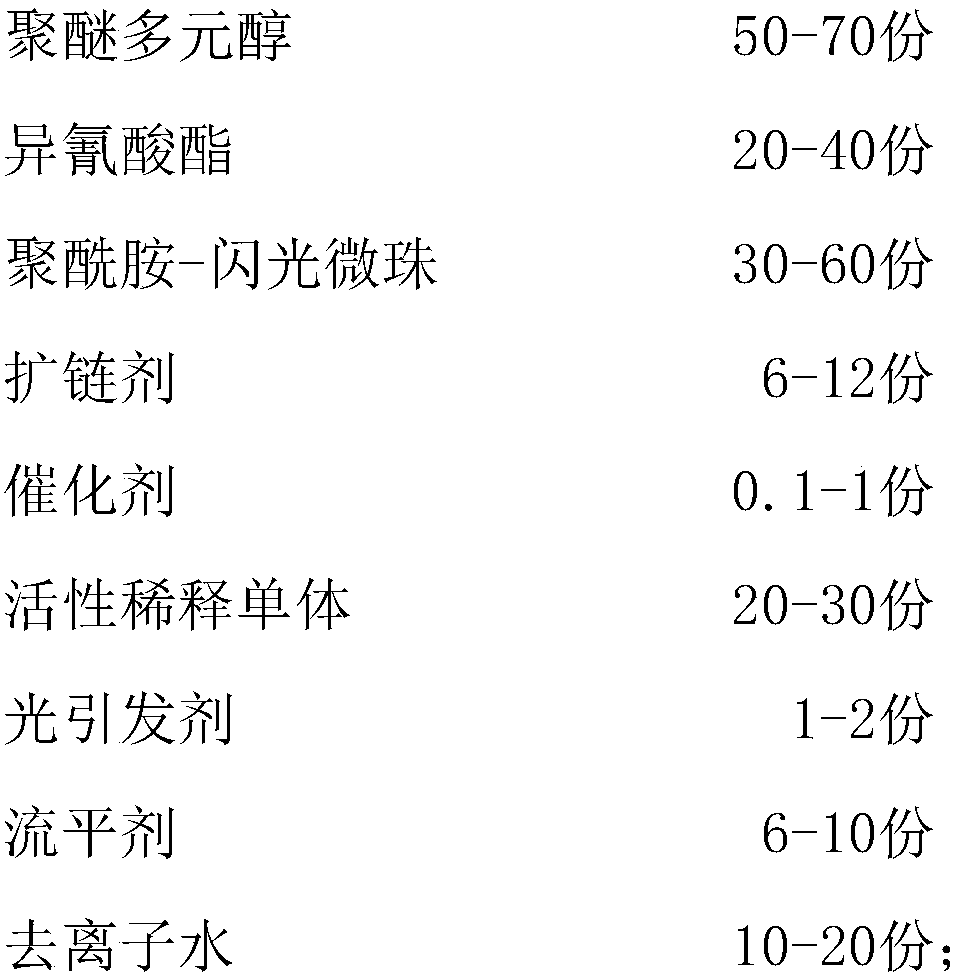

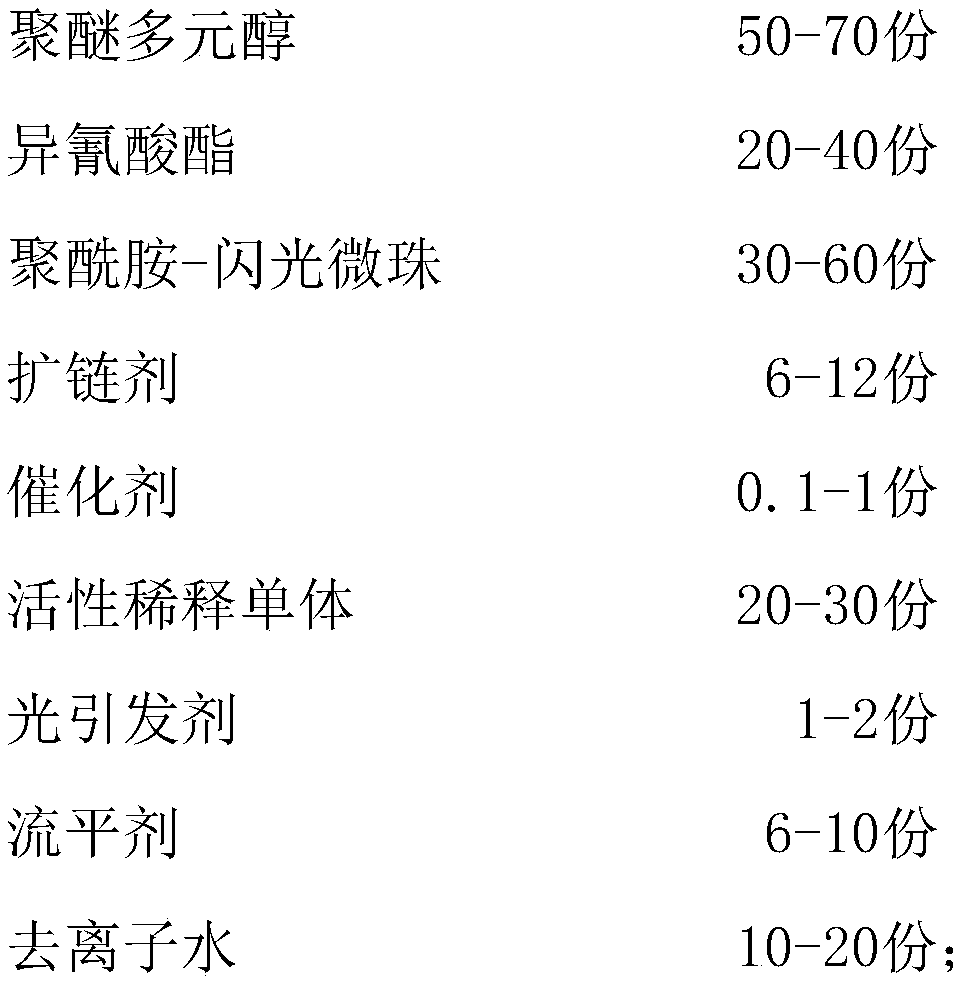

[0030] A preparation method for a polyurethane flash waterproof coating for slide fasteners, comprising the steps of:

[0031] (1) Preparation of polyurethane prepolymer: Mix 60 parts by weight of polyether polyol, 0.5 parts by weight of catalyst, and 30 parts by weight of isocyanate, heat up to 60°C to obtain a mixed solution, and add 15 parts by weight of polyamide to the mixed solution - Glitter microbeads and 9 parts by weight of a chain extender, heated up to 75°C, and reacted for 5 hours to obtain a polyurethane prepolymer;

[0032] (2) Preparation of coating: the polyurethane prepolymer obtained by adding 30 parts by weight of polyamide-glitter beads, 25 parts by weight of reactive diluent monomer, 1.5 parts by weight of photoinitiator and step (1) into 15 parts by weight of After stirring in deionized water at a speed of 1300 rpm for 12.5 minutes, 8 parts by weight of a leveling agent was added, and the mixture was stirred at 500 rpm for 9 minutes to obtain the polyure...

Embodiment 2

[0044] A preparation method for a polyurethane flash waterproof coating for slide fasteners, comprising the steps of:

[0045] (1) Preparation of polyurethane prepolymer: Mix 50 parts by weight of polyether polyol, 0.1 part by weight of catalyst, and 20 parts by weight of isocyanate, heat up to 50°C to obtain a mixed solution, and add 10 parts by weight of polyamide to the mixed solution - Flash microbeads and 6 parts by weight of a chain extender are heated up to 70°C and reacted for 3.5 hours to obtain a polyurethane prepolymer;

[0046] (2) Preparation of coating: 20 parts by weight of polyamide-glitter beads, 20 parts by weight of reactive diluent monomer, 1 part by weight of photoinitiator and the polyurethane prepolymer obtained in step (1) are added to 10 parts by weight of After stirring in deionized water at a speed of 1200 rpm for 15 minutes, 6 parts by weight of a leveling agent was added, and the mixture was stirred at a speed of 400 rpm for 12 minutes to obtain th...

Embodiment 3

[0058] A preparation method for a polyurethane flash waterproof coating for slide fasteners, comprising the steps of:

[0059] (1) Preparation of polyurethane prepolymer: Mix 70 parts by weight of polyether polyol, 1 part by weight of catalyst, and 40 parts by weight of isocyanate, heat up to 70°C to obtain a mixed solution, and add 20 parts by weight of polyamide to the mixed solution - Glitter microbeads and 12 parts by weight of a chain extender, heated up to 80°C, and reacted for 7 hours to obtain a polyurethane prepolymer;

[0060] (2) Preparation of coating: 40 parts by weight of polyamide-glitter beads, 30 parts by weight of reactive diluting monomer, 2 parts by weight of photoinitiator and the polyurethane prepolymer obtained in step (1) are added to 20 parts by weight of After stirring at 1400 rpm for 10 minutes in deionized water, 10 parts by weight of a leveling agent was added, and the mixture was stirred at 600 rpm for 6 minutes to obtain the polyurethane flash wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com