Brewing equipment for kaoliang spirit

A sorghum wine and equipment technology, applied in the field of sorghum wine manufacturing equipment, can solve the problems of serious proportion of sorghum porridge, prolonged cooking time, slow fermentation process, etc., and achieve the effects of enhanced centrifugal effect, improved wine yield, and uniform cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

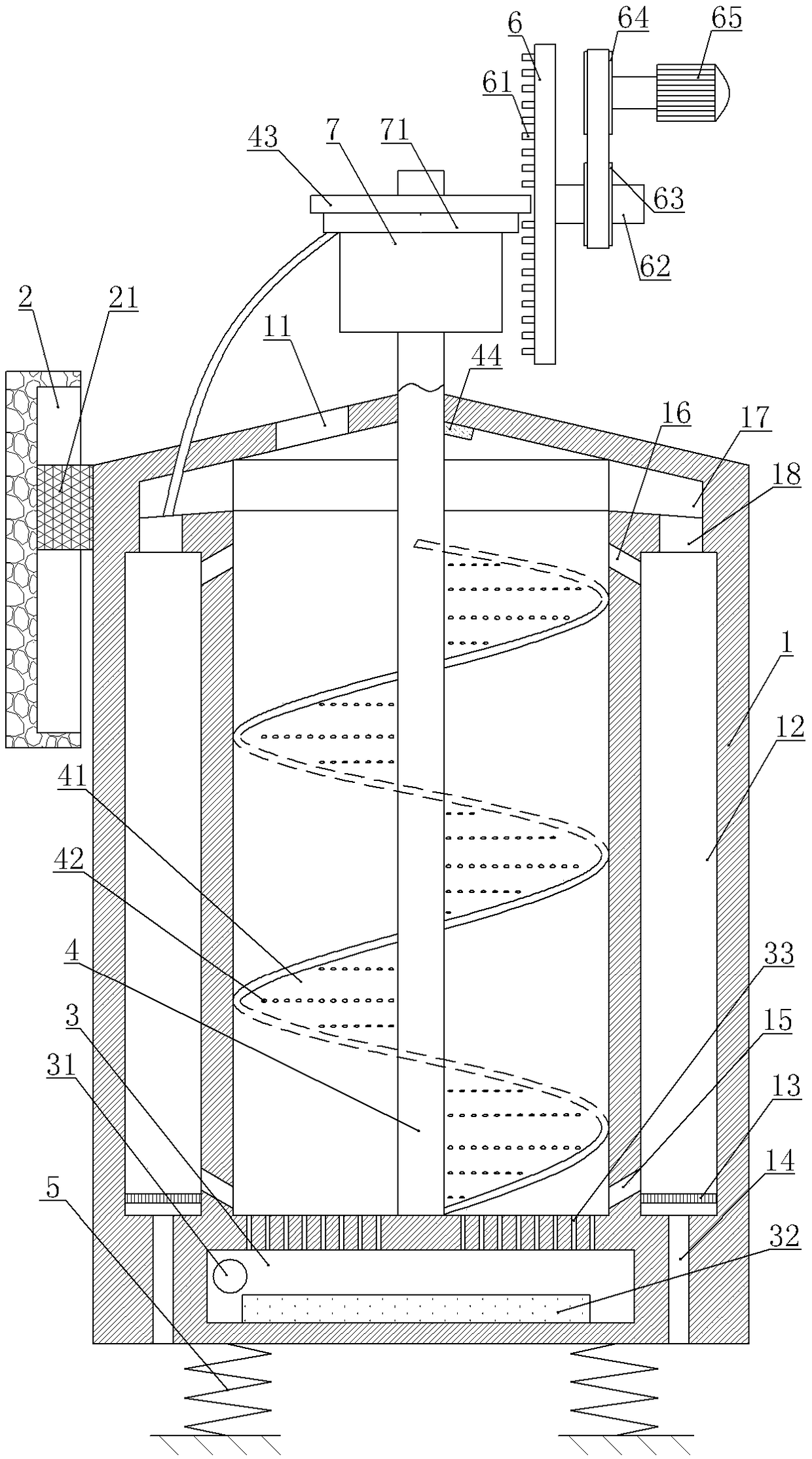

[0025] The reference signs in the accompanying drawings of the specification include: steam barrel 1, exhaust port 11, accommodating cavity 12, filter screen 13, drain port 14, outlet 15, inlet 16, sump 17, communication channel 18, chute 2, chute Block 21, air intake cavity 3, steam port 31, heating element 32, air intake hole 33, rotating shaft 4, lifting blade 41, through hole 42, pin gear 43, limit block 44, support spring 5, turntable 6, bump 61, rotating shaft 62, driven wheel 63, driving wheel 64, motor 65, water tank 7, outer cover 71.

[0026] Sorghum wine brewing equipment, such as figure 1 As shown, it includes a frame, a steamer 1, a lifting mechanism and a driving mechanism. The left side of the steamer 1 is provided with a chute 2 welded on the frame in the vertical direction, and the top of the left wall of the steamer 1 is welded with a chute 2 along the vertical dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com