Method used for transferring big diameter plastic pipes and composite coiled pipes and clamps

A technology for plastic pipes and coiled pipes, applied in the field of transferring large-diameter plastic pipes and composite coiled pipes, can solve the problems of large safety risks, super high coils, discounts, etc., and achieve convenient transfer operations, reduce transportation costs, and reduce outer diameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

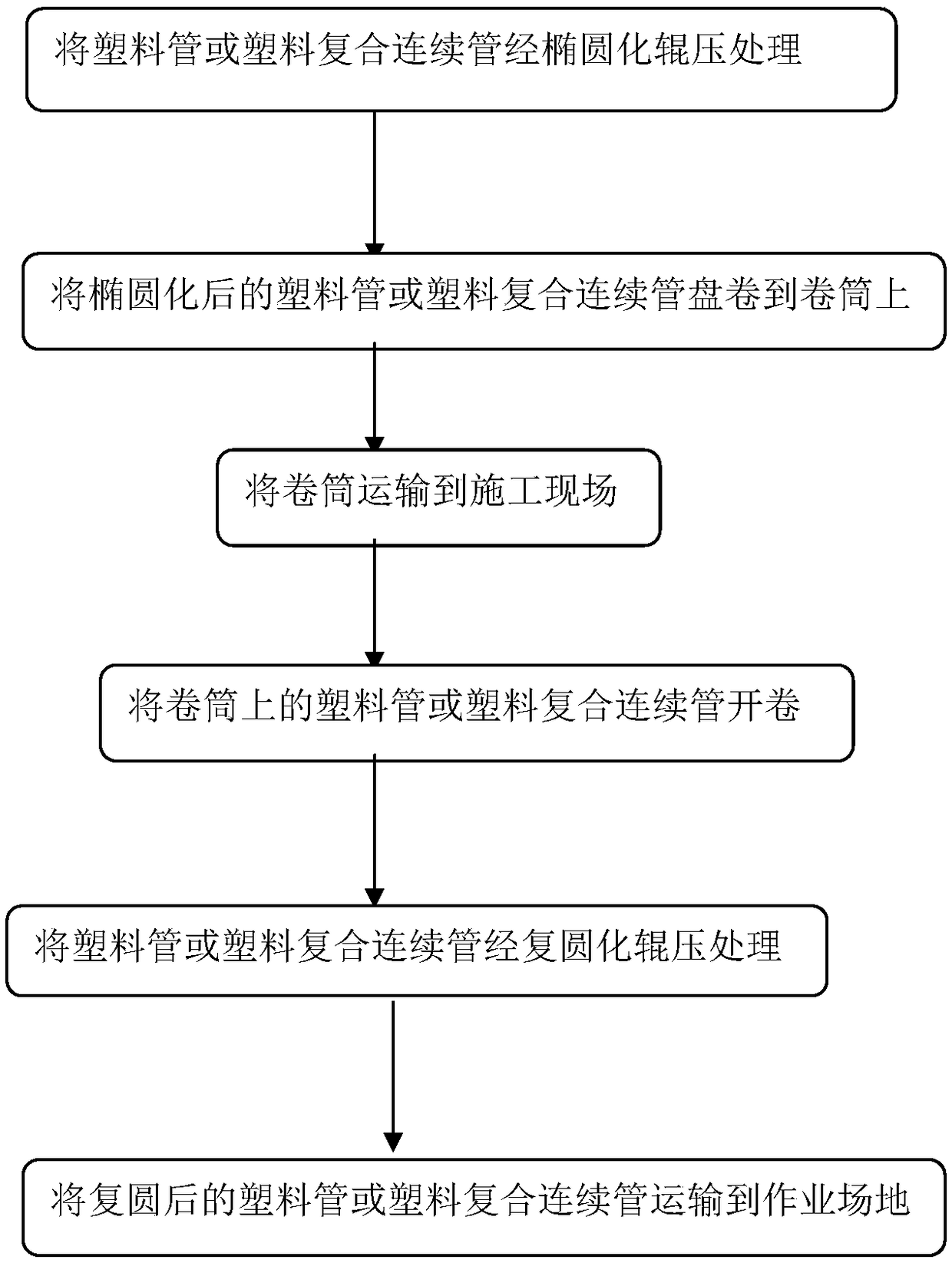

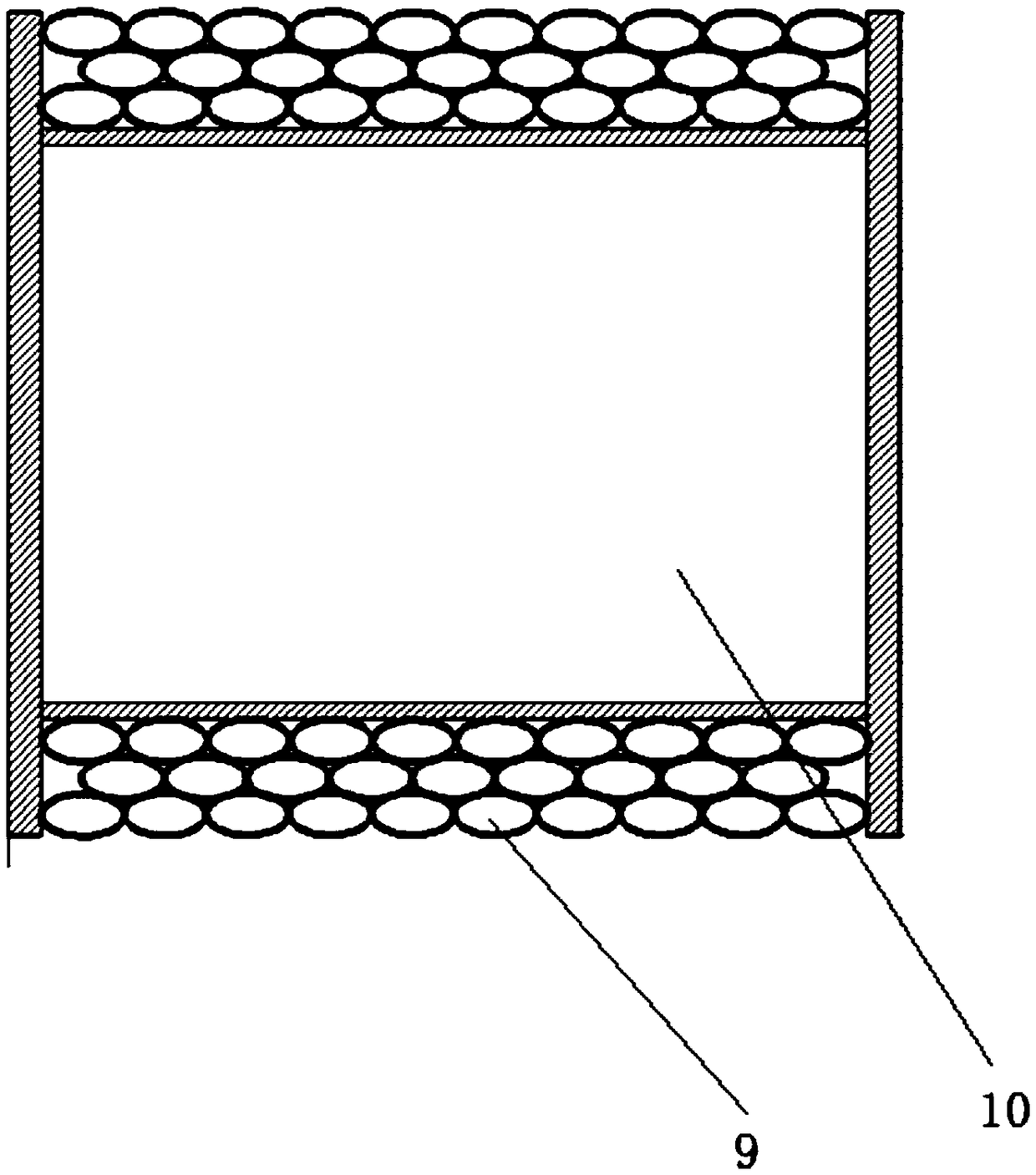

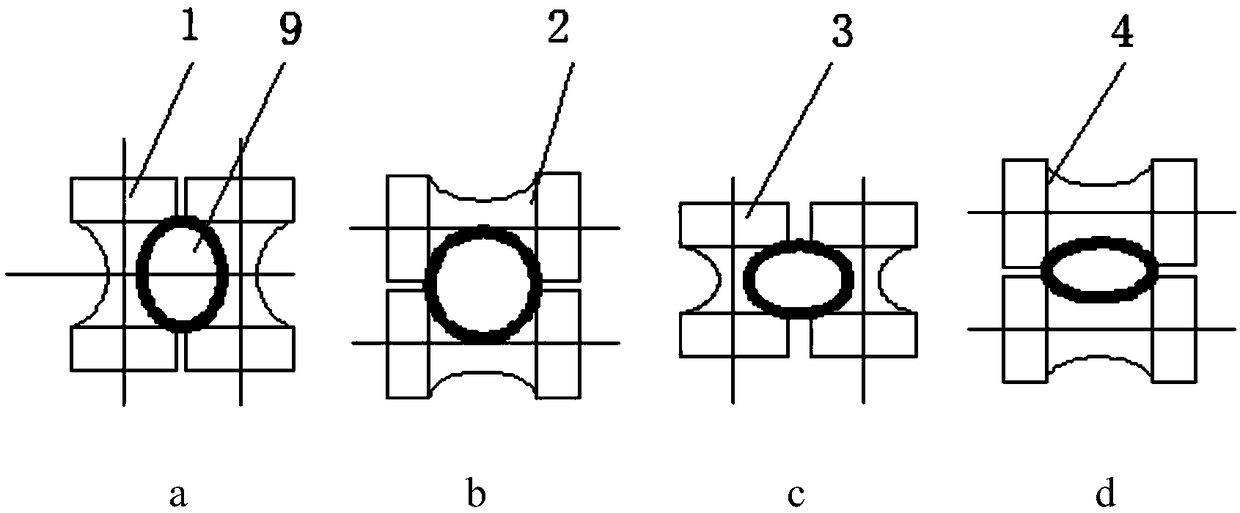

[0045] Such as Figure 1 to Figure 4 As shown, the invention provides a method for transshipment of large-diameter plastic pipes and composite continuous pipes, from figure 1 It can be seen from the figure that the present invention mainly includes the process of ovalizing and rolling the plastic pipe and the composite continuous pipe 9, coiling the ovalized plastic pipe and the composite continuous pipe onto the reel 10, and transporting the reel 10 to the construction site. On site, the plastic pipe and composite coiled pipe on the reel 10 are uncoiled, the plastic pipe and composite coiled pipe are rounded and rolled, and the rounded plastic pipe and composite coiled pipe are transported to the work site.

[0046] Each step is described in detail below:

[0047] 1) The plastic pipe and composite continuous pipe are subjected to elliptical rolling treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com