Conveying device for textiles

A technology of conveying equipment and cloth feeding table, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc. It can solve the problems of bacteria breeding and easy yellowing of cloth, so as to save energy, increase practicability, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

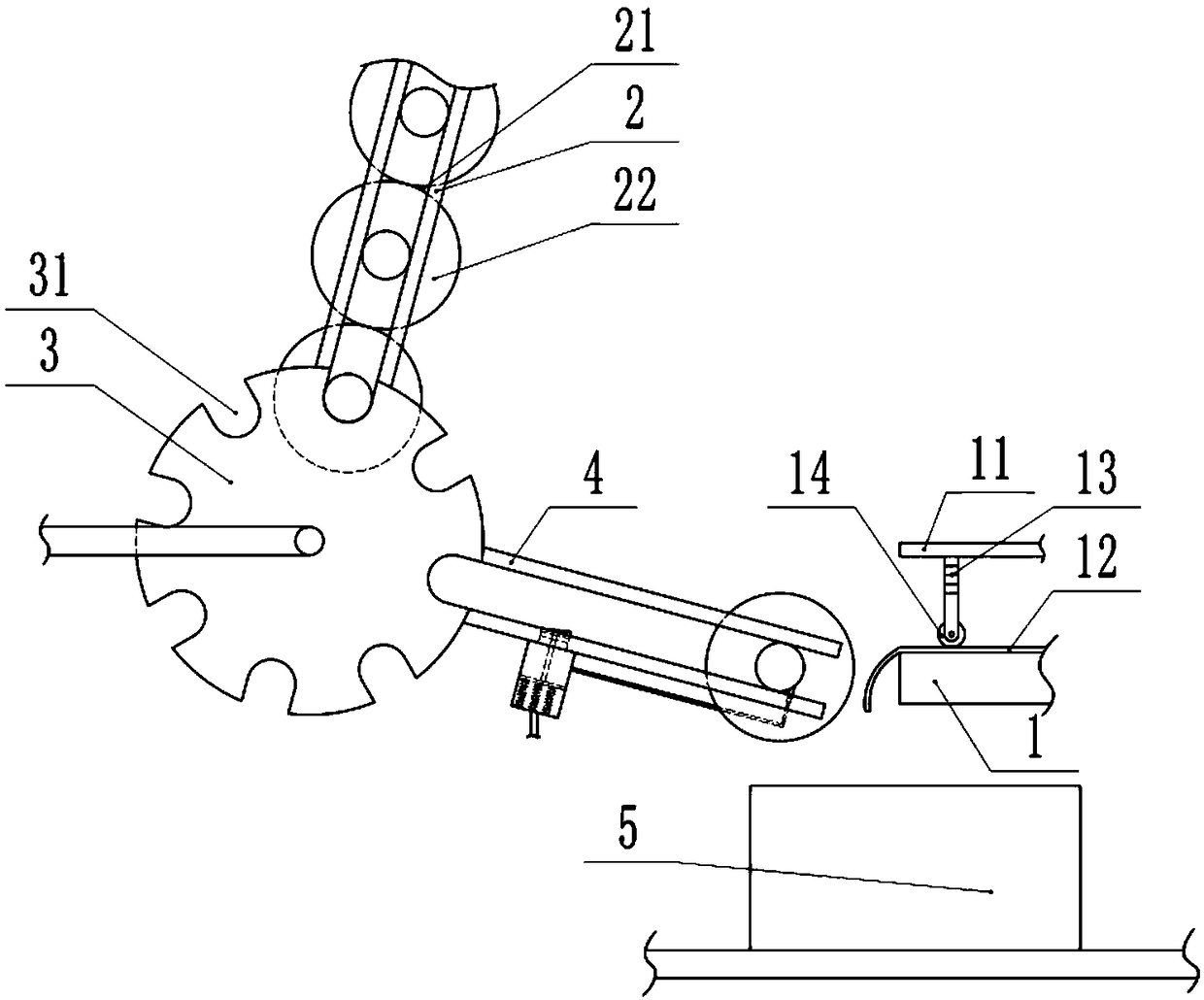

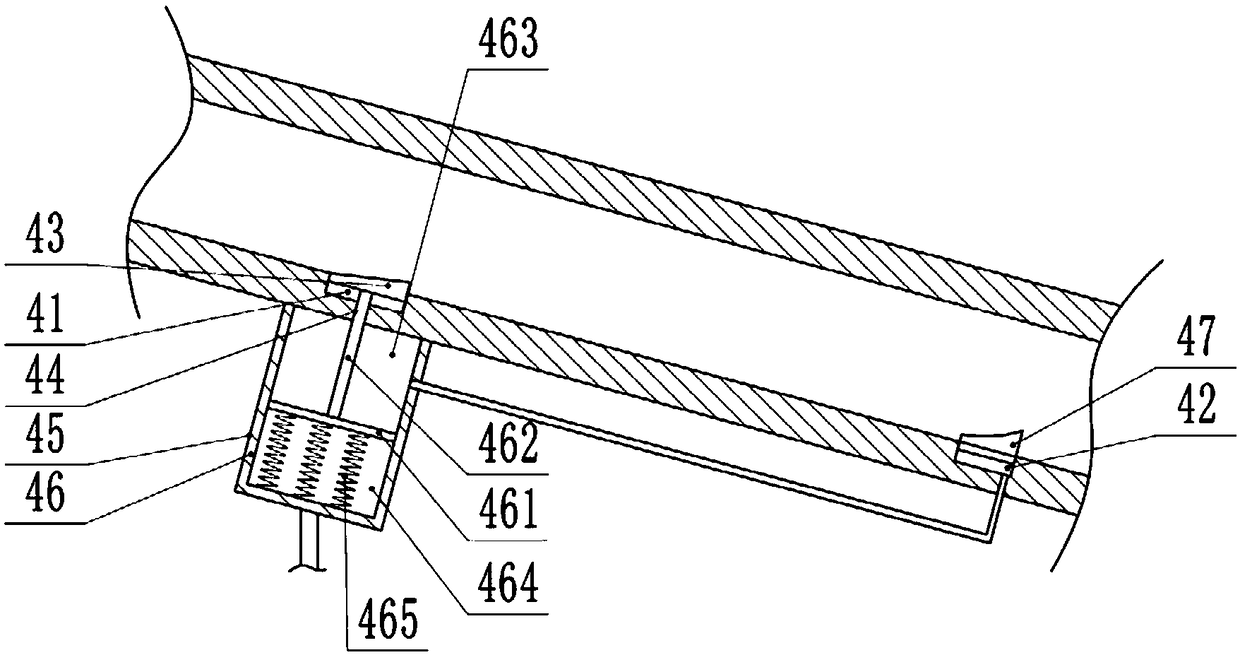

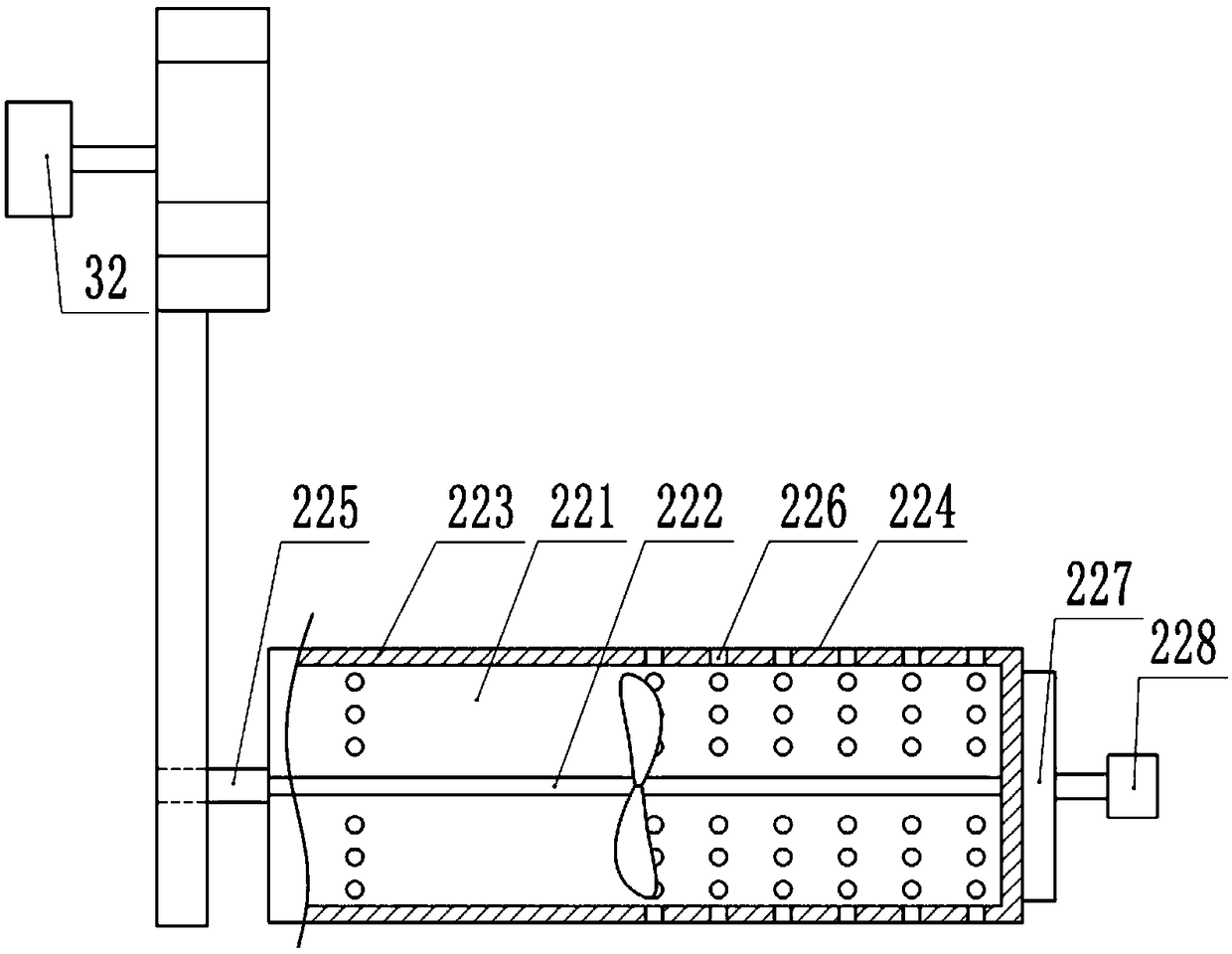

[0030] The reference signs in the accompanying drawings of the specification include:

[0031] Cloth feeding table 1, frame 11, cloth 12, telescopic rod 13, pressure roller 14, storage cylinder 2, through groove 21, empty roller 22, index plate 3, groove 31, first servo motor 32, roll Cloth track 4, first cavity 41, second cavity 42, wedge block 43, through hole 44, fixed chamber 45, piston chamber 46, piston 461, piston rod 462, upper chamber 463, lower chamber 464, spring 467, block 47, third cavity 221, central shaft 222, drive half roller 223, adsorption half roller 224, drive shaft 225, thin through hole 226, grinding block 227, second servo motor 228, collection box 5.

[0032] The present invention will be described in further detail below by means of specific embodiments:

[0033] Conveying equipment for textiles, such as figure 1 As shown, it includes a cloth feeding table 1 and a frame 11. The bottom of the cloth feeding table 1 is fixedly connected with four pilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com