Finished product conveying device for clothes production

A technology for conveying devices and finished products, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as optimization, cleaning, and overall product quality decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

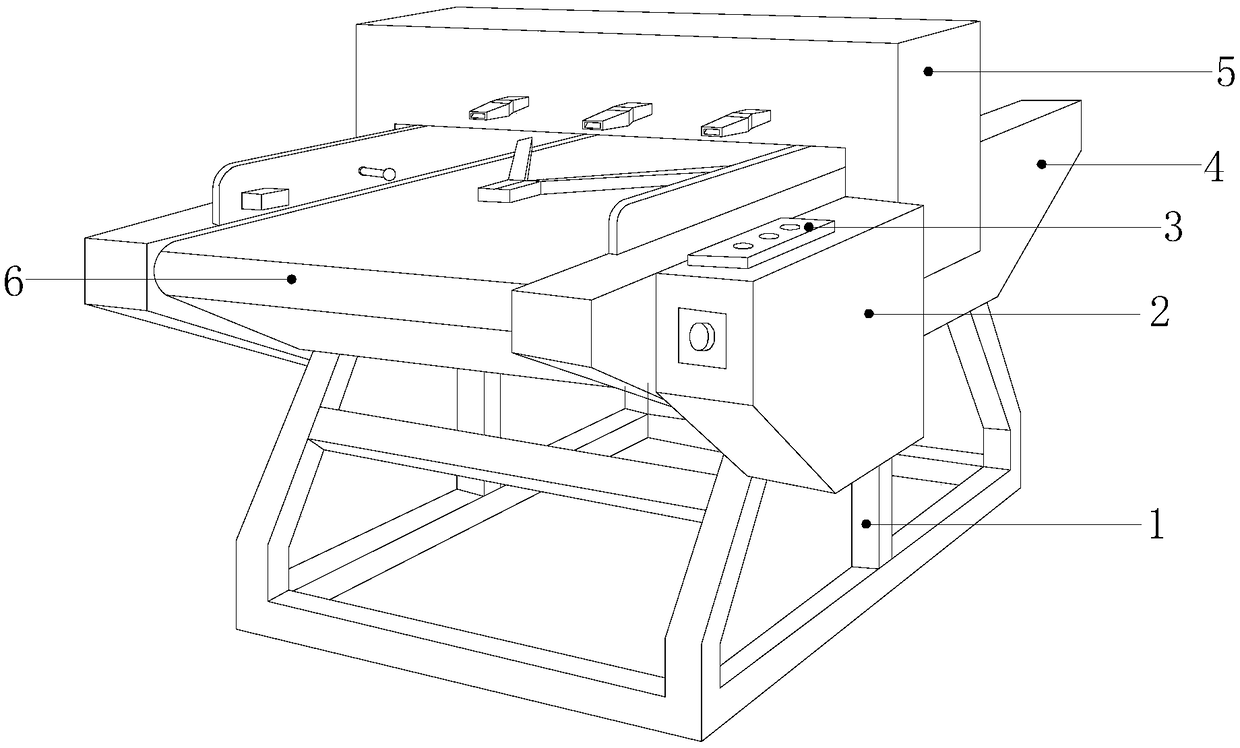

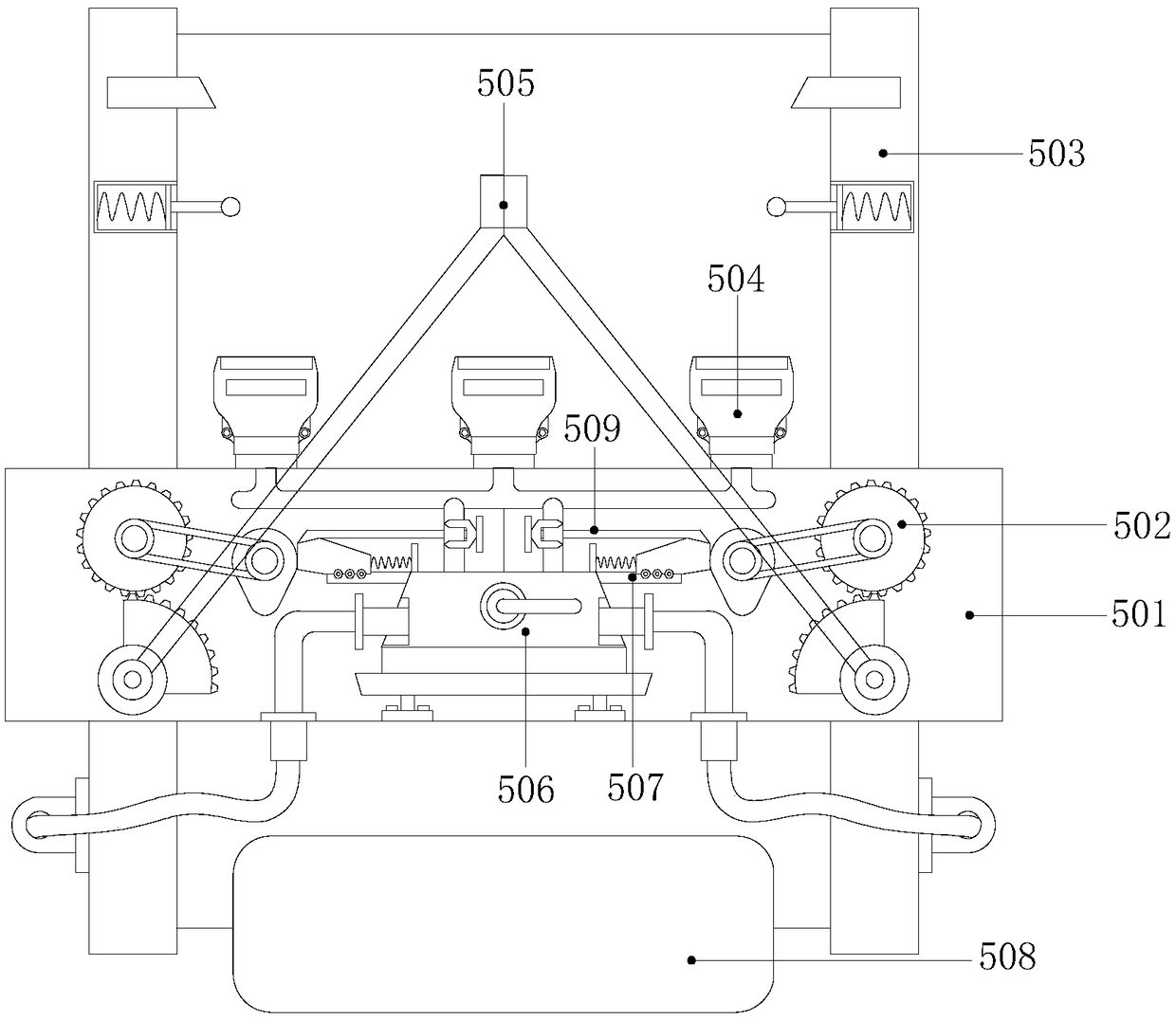

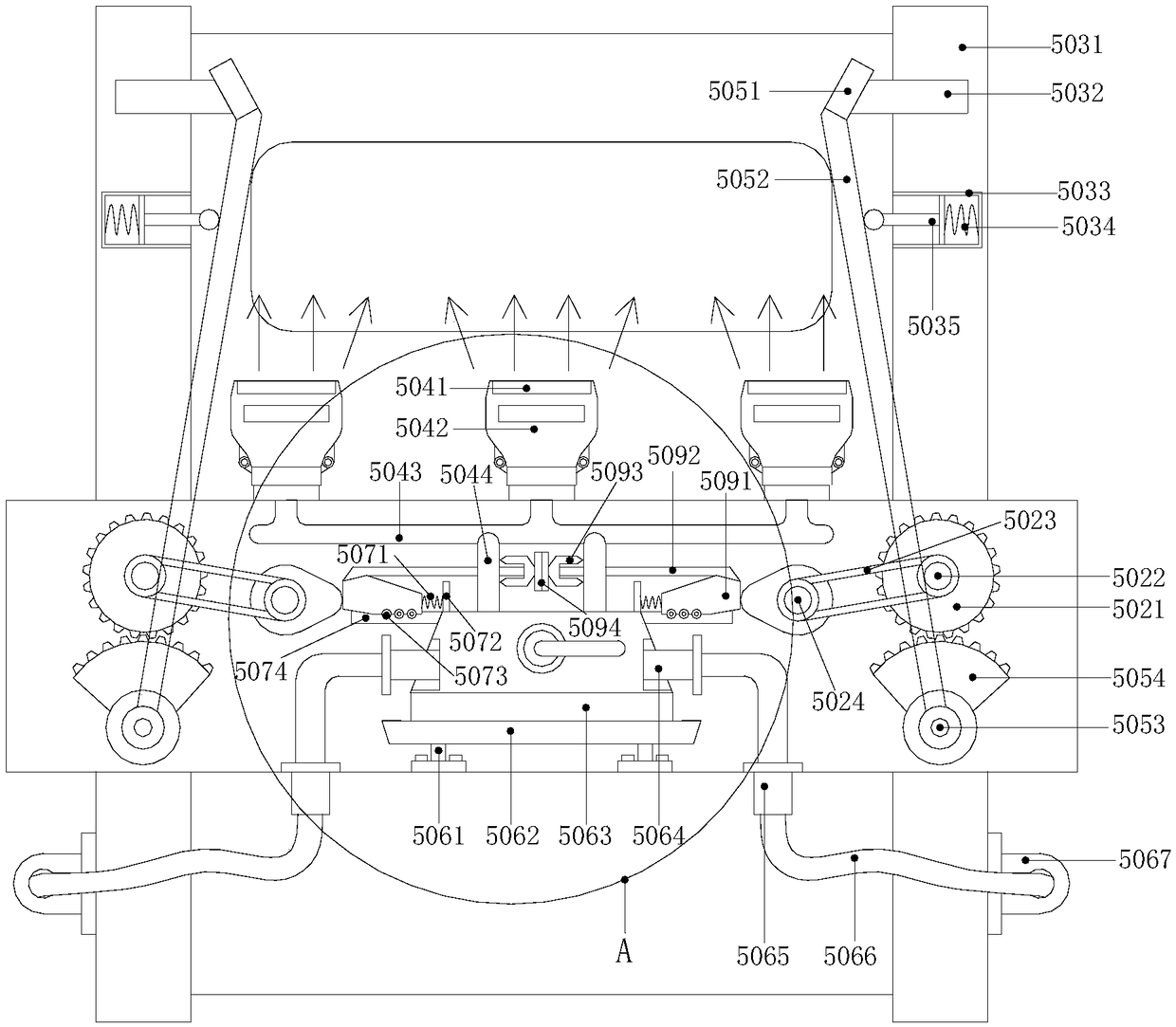

[0021] see Figure 1-Figure 4, the present invention provides a finished product conveying device for garment production, its structure includes a fixed bracket 1, a controller 2, a control panel 3, a fixed side arm 4, a gantry frame 5, and a conveyor belt 6, and the upper end of the fixed bracket 1 is provided with a conveyor belt 6 , the left and right sides of the conveyor belt 6 are respectively provided with fixed side arms 4, the gantry 5 is a "Xi"-shaped structure, and the two ends of the slot are buckled with the fixed side arms 4, and the controller 2 is connected through the buckle It is installed on the front end of the fixed side arm 4 in a combined manner, and the top is provided with a groove for movable installation of the control panel 3. The gantry 5 includes a gantry main body 501, a linkage mechanism 502, a side arm main body 503, an air blowing device 504, a transmission Mechanism 505, air supply device 506, reset mechanism 507, conveying member 508, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com