New airtight packaging container

A new type of sealing packaging technology, which is applied in the field of containers, can solve problems such as the instability of the anti-tripping structure and the decline in sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

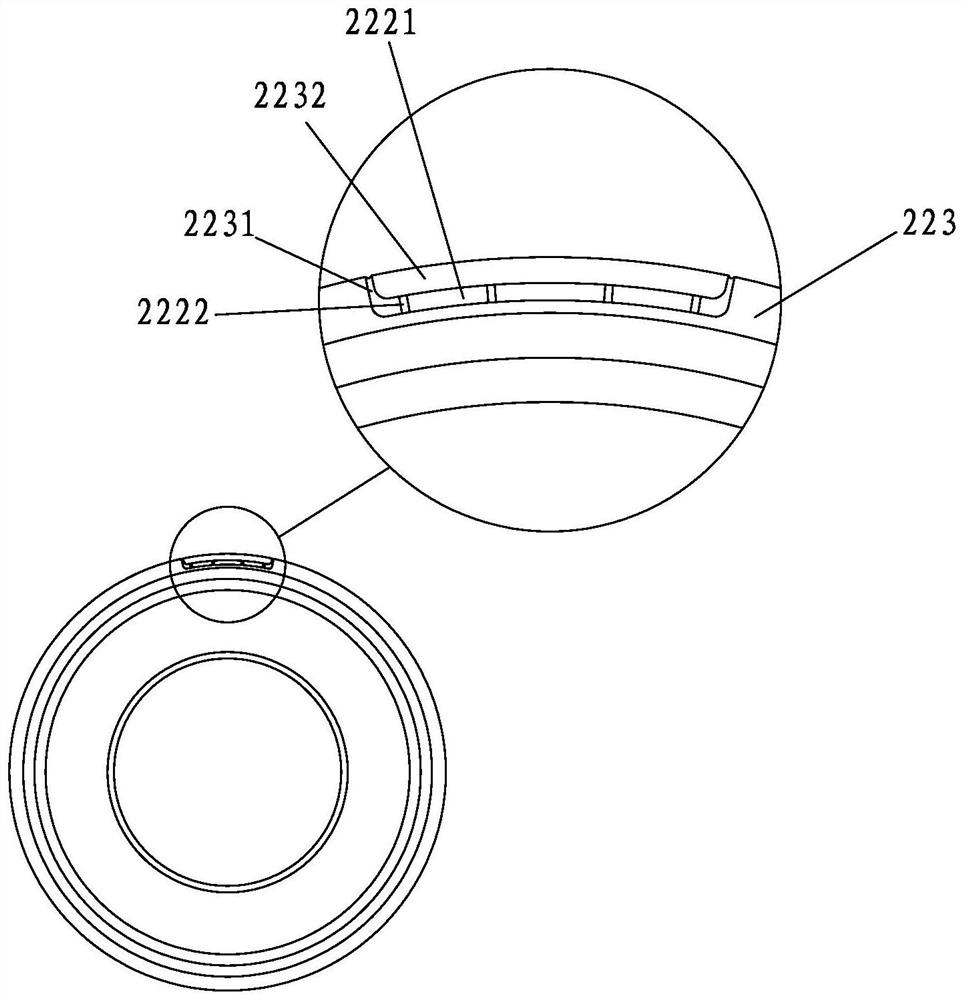

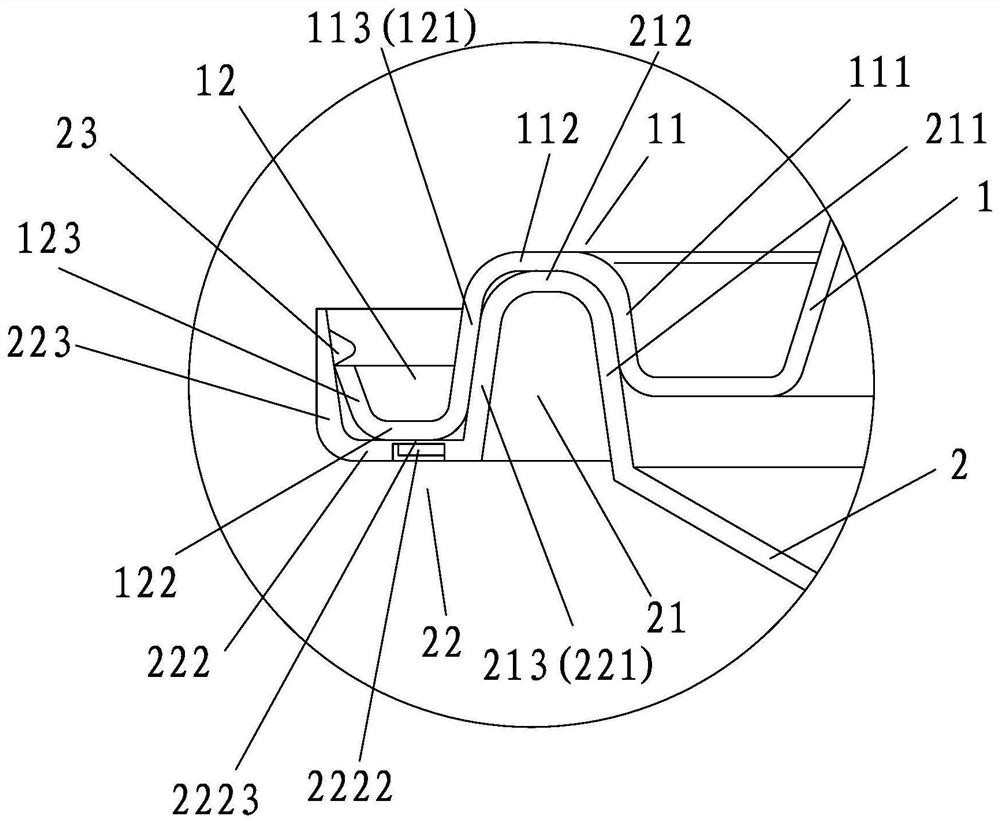

[0035] A new type of sealed packaging container of the present invention, as shown in Figure 1-2, comprises a box cover 1 and an open box body.

[0037] The mouth of the box body 2 is bent upward and extends to form the inner groove wall 211 of the second inner matching groove 21. The second inner groove wall 211 is formed.

[0039] The limiting protrusions 23 are distributed on the inner side of the outer groove wall 223 of the second outer matching groove along the circumferential direction, so

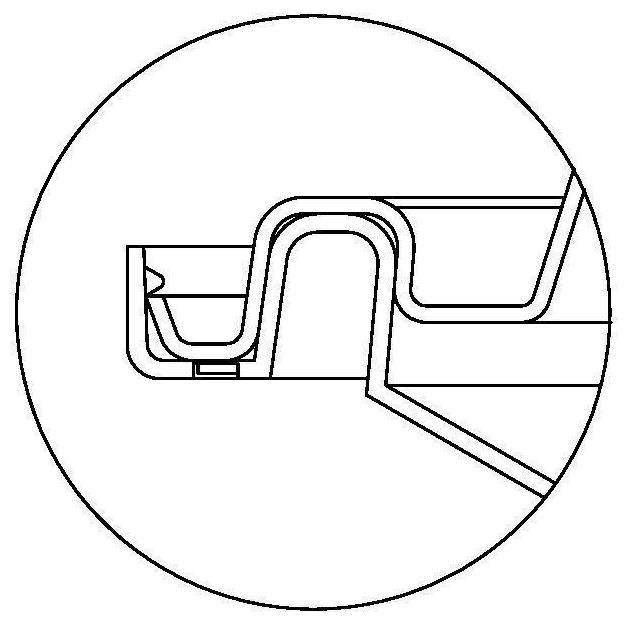

[0041] The novel sealed packaging container of the present invention, through the taper matching of the first inner matching groove 11 and the second inner matching groove 21,

[0042] The upper end of the outer groove wall 123 of the first outer matching groove is inclined upwardly and outwardly to be tensioned and held against the outer surface of the second outer matching groove.

[0043] The outer groove wall 223 of the second outer matching groove extends downward from the upper end ...

Embodiment 2 8

[0047] As shown in Figures 3-9, Embodiments 2-8 are the deformation structures of Embodiment 1, specifically, the second inner matching groove is

Embodiment 9

[0050] As shown in FIG. 10 , the difference between this embodiment and the first embodiment is only that the limit bump 23 is omitted, and the second outer matching groove

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com