Track shoe structure of a mechanical crane

A crane and mechanical technology, which is applied in the field of crawler shoe structure of mechanical cranes, can solve problems such as slipping, and achieve the effect of convenient connection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

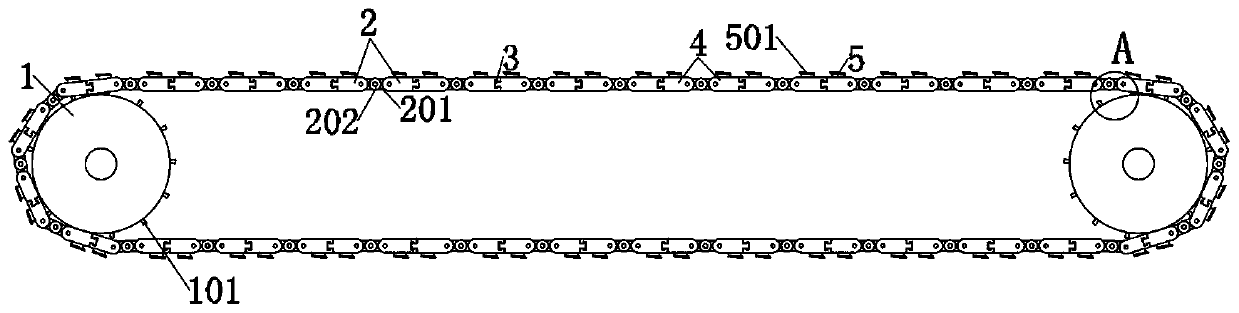

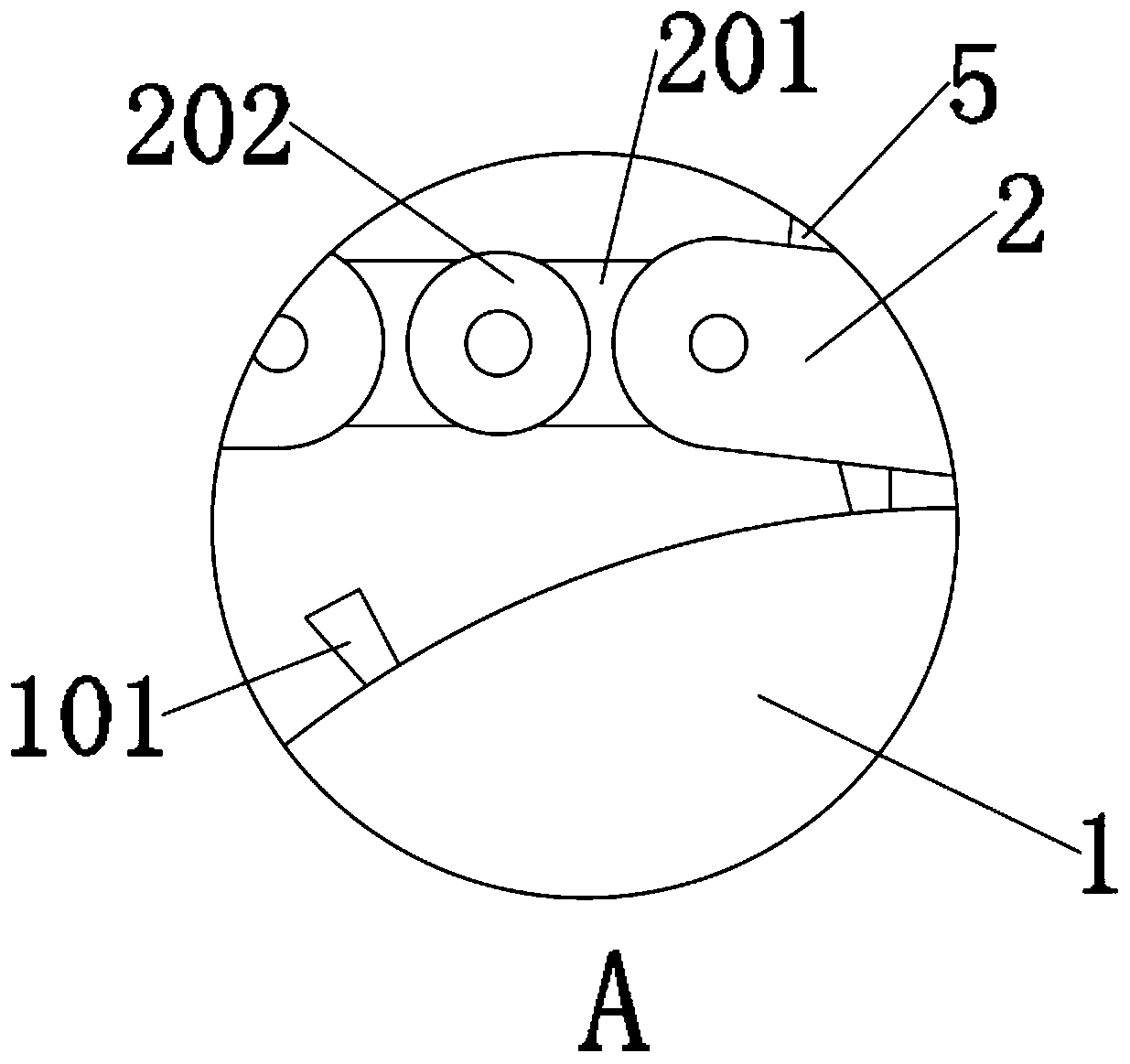

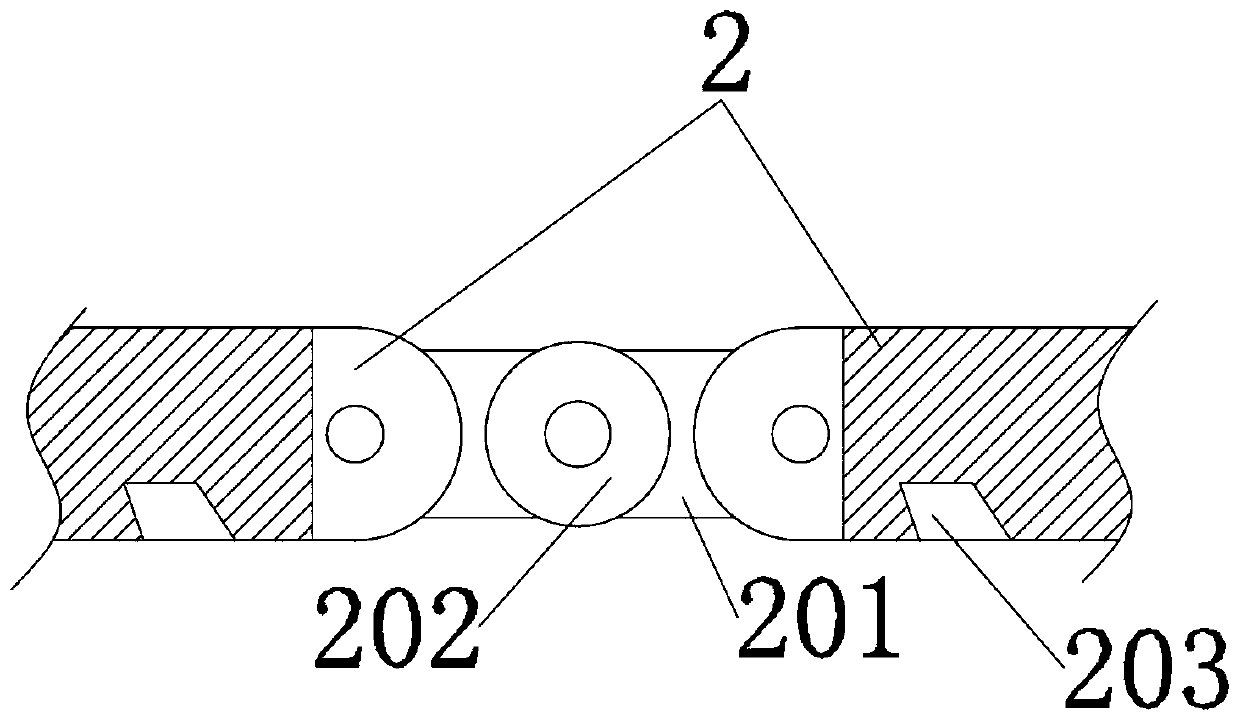

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The present invention provides a track shoe structure of a mechanical crane, which includes: a runner 1, a receiving part 101, a clamping part 2, a connecting part 201, a connecting shaft 202, a moving groove 203, a clamping head 3, an outer support spring 301, a limiter Position piece 302, kit 4, embedding groove 401, limit hole 402, support piece 5 and insert piece 501; runner 1 is a cylindrical structure, and runner 1 is installed on the bottom of both sides of the crane through a connecting shaft; runner 1 The outer receiving part 101 is installed inside the moving groove 203 at the bottom of the clip 2 and the kit 4 by means of insertion; the clip 2 is embedded and installed inside the embedded groove 401 of the T-shaped structure on both sides of the kit 4 through the chuck heads 3 on both sides. And the two ends of the clip 2 and the kit 4 are nested on the outside of the two runners 1; the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com