Automobile lower arm assembly

A technology of automobile lower swing arm and assembly, which is applied to vehicle parts, cantilevers mounted on pivots, transportation and packaging, etc., can solve the problems of generality deviation, low structural strength, small section size, etc., and achieve less stress Concentrate, improve the fatigue durability of welds, and strengthen the effect of local stress tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] In the present invention, "above" means above the height of the vehicle body; "below" means below the height of the vehicle body; "longitudinal" means the direction from the front of the vehicle to the rear of the vehicle; "lateral" means the width direction of the vehicle; The rear of the car is closer to the front of the car, and "rear" refers to the direction from the front to the rear of the car that is closer to the rear of the car.

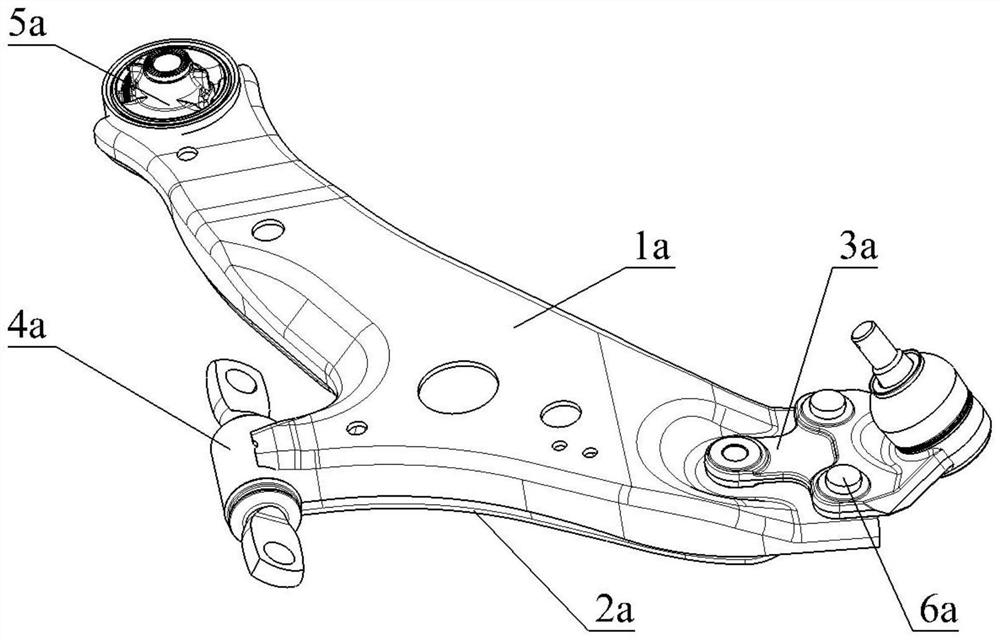

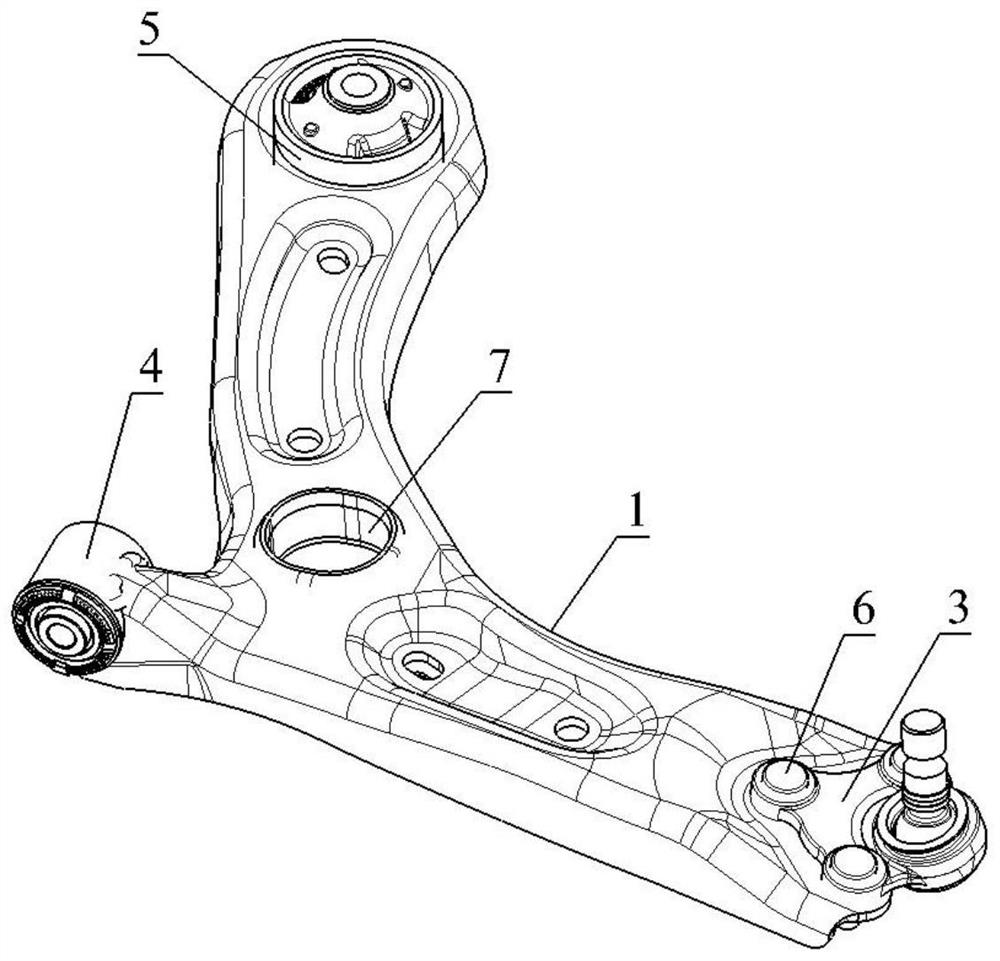

[0030] see Figure 3 to Figure 7 , The automobile lower swing arm assembly disclosed in the present invention includes: a swing arm and a lower plate 2 for reinforcing the swing arm. The swing arm includes a small bushing hole body assembly 4 , a large bushing hole body assembly 5 , a ball stud assembly 3 and a swing arm body 1 . In the assembled state, the ball stud assembly 3 is connected to the steering knuckle through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com