Small mortar transfer trolley

A transfer vehicle and mortar technology, which is applied in the direction of concrete transportation, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of increasing labor intensity and labor costs, low efficiency of mortar handling, and affecting the use of trolleys, etc., to achieve good promotion and Use value, reduce labor intensity and labor cost, good transshipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

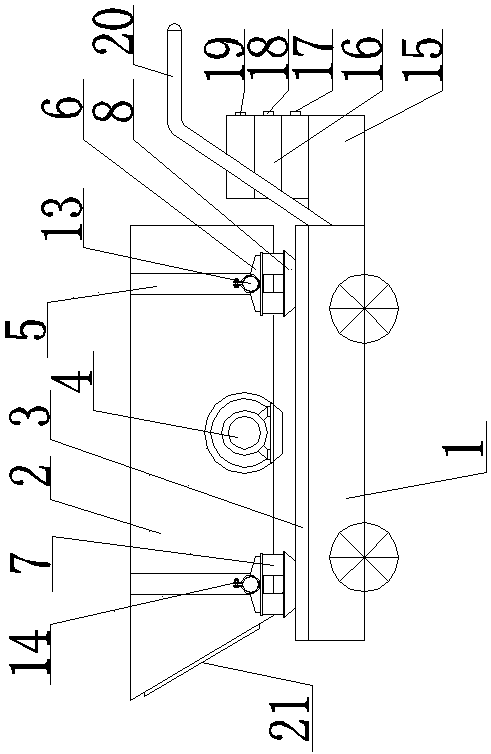

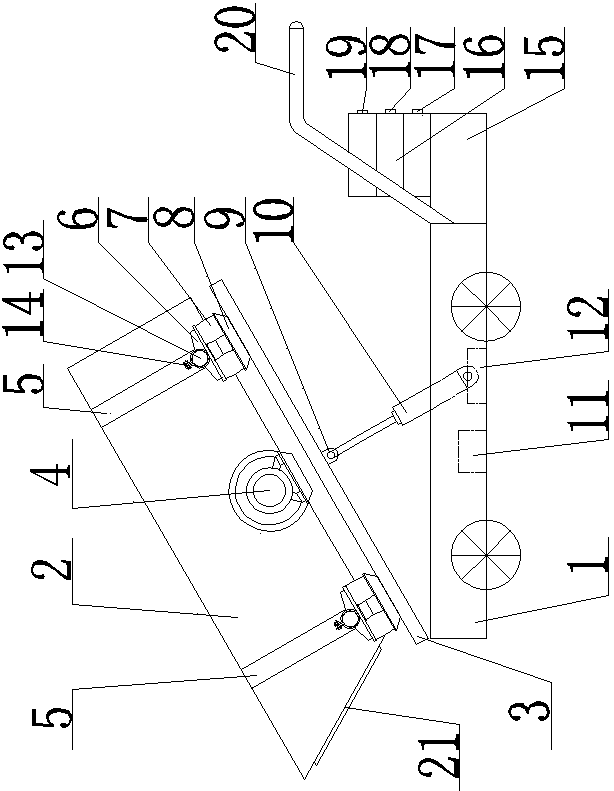

[0026] A small mortar transfer vehicle of the present invention comprises a vehicle body 1 and a charging box 2, the charging box 2 is arranged on the vehicle body 1, the section of the charging box 2 is a trapezoidal structure and the front end of the charging box 2 is provided with a discharge port 21; A connecting plate 3 is arranged between the charging box 2 and the vehicle body 1, and the connecting plate 3 is connected with the top surface of the vehicle body 1; a vibration exciter 4 is fixed on the outer wall of the charging box 2; There are 2 pairs of buffer devices, the buffer device includes a fixed plate 5, an upper support seat 6, a rubber spring 7 and a lower support seat 8, the fixed plate 5 is fixed on the outer wall of the charging box 2, the bottom end of the fixed plate 5 is connected to the upper support The top of the seat 6 is fixedly connected, and the outer wall of the bottom end of the fixed plate 5 is fixed with a connecting column 13. The connecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com