Oral liquid bottle cap assembly system

An assembly system and oral liquid technology, applied in transportation and packaging, metal processing equipment, metal processing, etc., can solve the problems of poor safety, high labor costs, scratched hands from the aluminum cover, and achieve good return and assembly effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

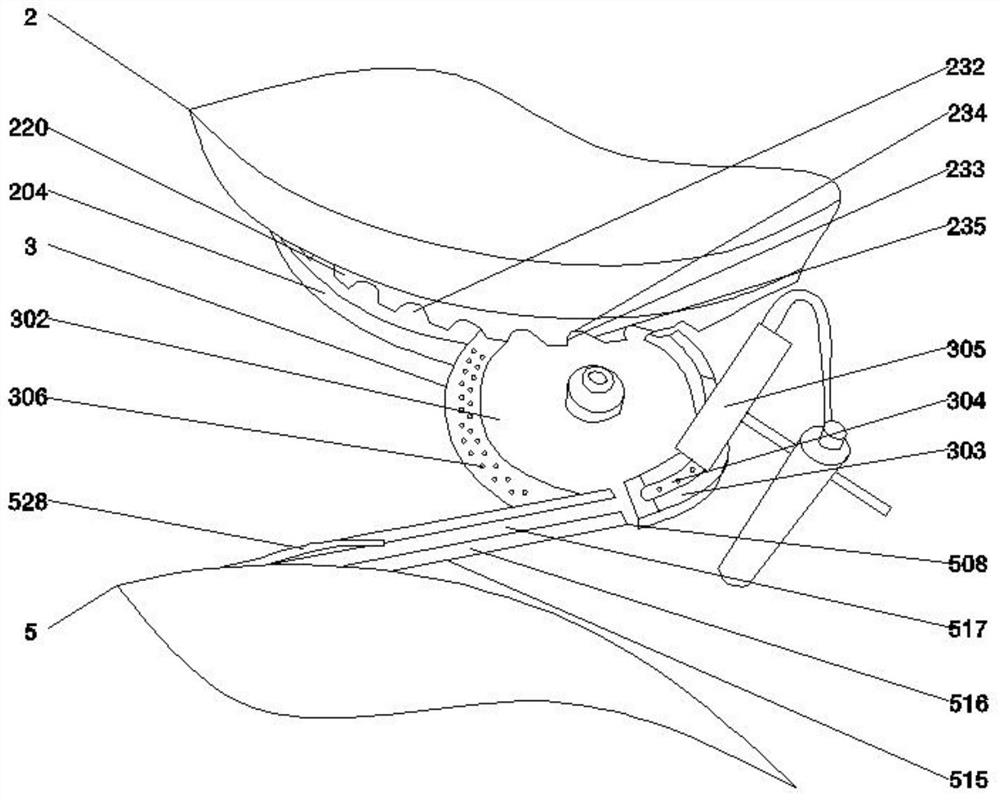

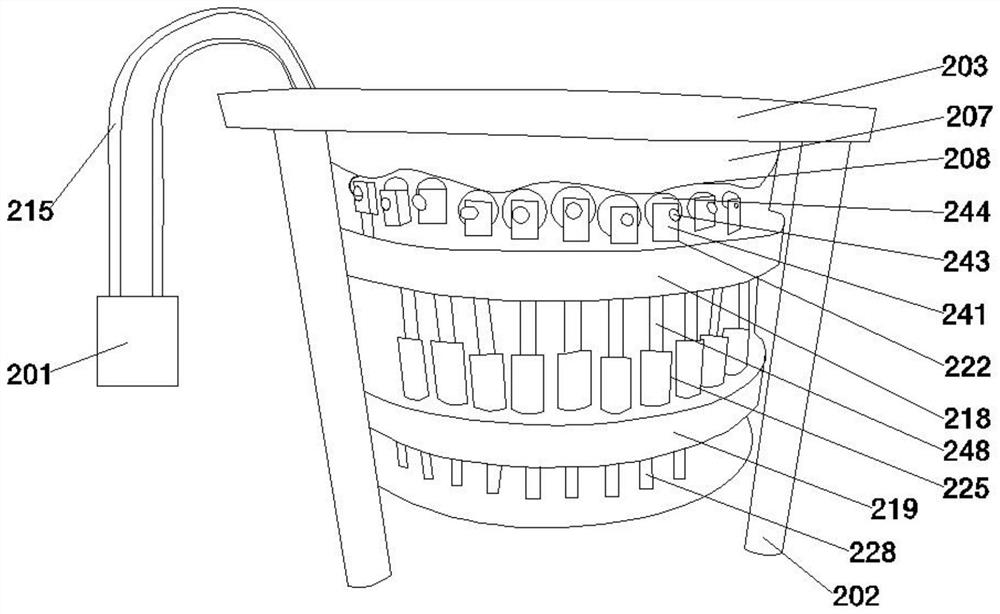

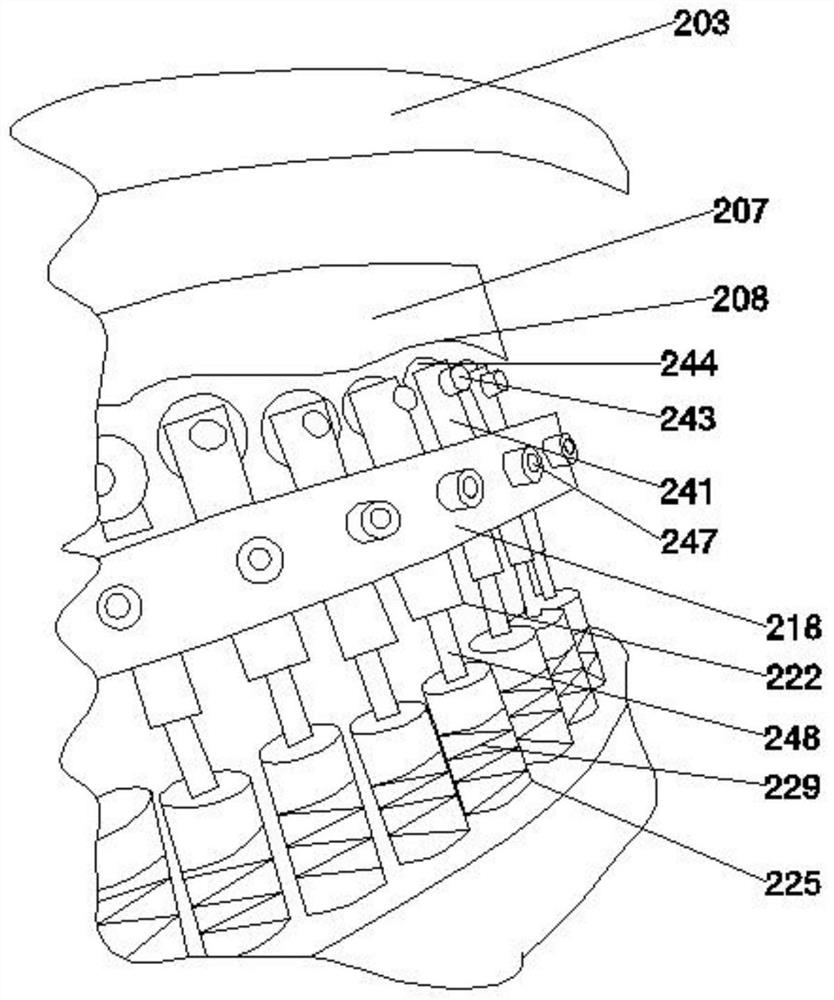

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9The oral liquid bottle cap assembly system shown includes a bracket 1, a plug mechanism 2 arranged on the bracket and an adjustment mechanism 3 arranged on the bracket to match the plug mechanism; the plug mechanism includes a vacuum pump arranged on the bracket 201. The top plate 203 and the bottom plate 204 set on the support through the pillar 202, the top plate and the bottom plate are respectively provided with a first through hole 205 and a second through hole 206, and the bottom of the top plate is close to the outer ring A semi-circular guide block 207 is provided, and the bottom of the guide block is provided with a wave-shaped guide rail 208. The bottom of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com