Tapping machine

A technology of tapping machine and connecting rod mechanism, which is applied in the field of tapping machine, can solve problems such as troublesome and difficult thread processing, and achieve the effects of reducing heat, liberating labor force, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

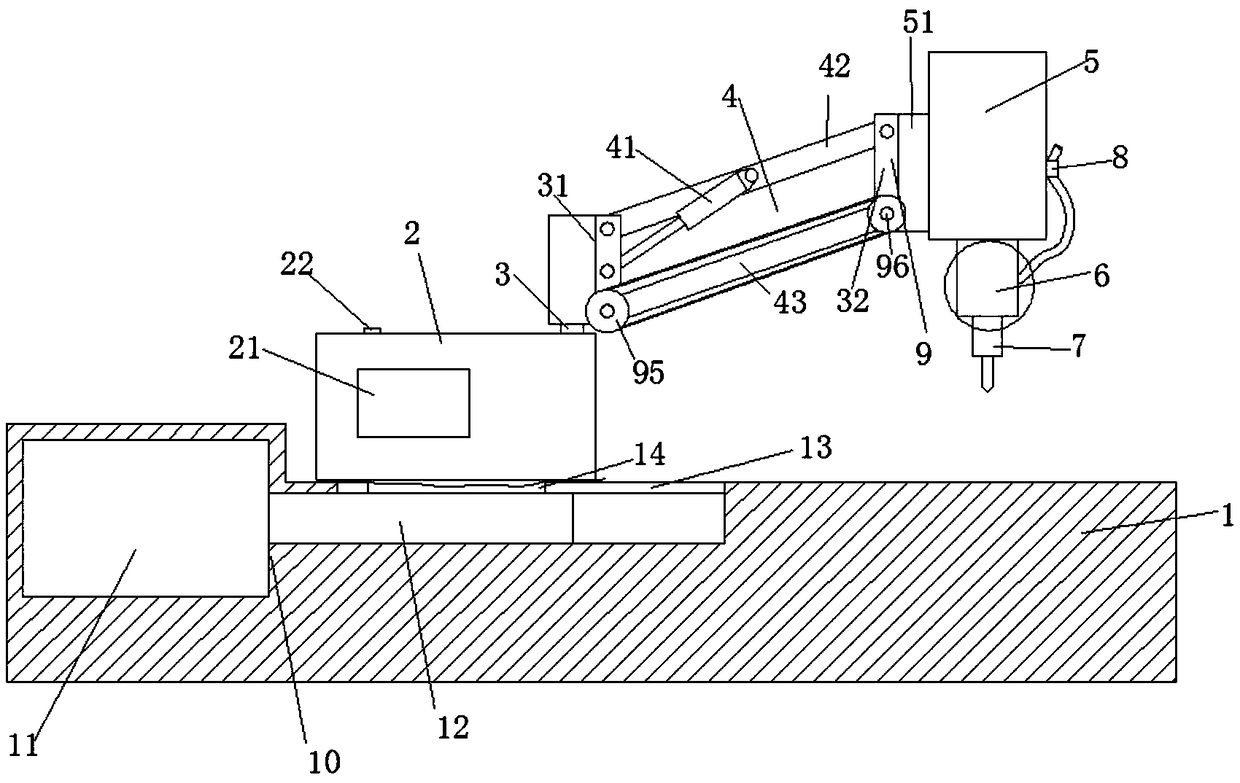

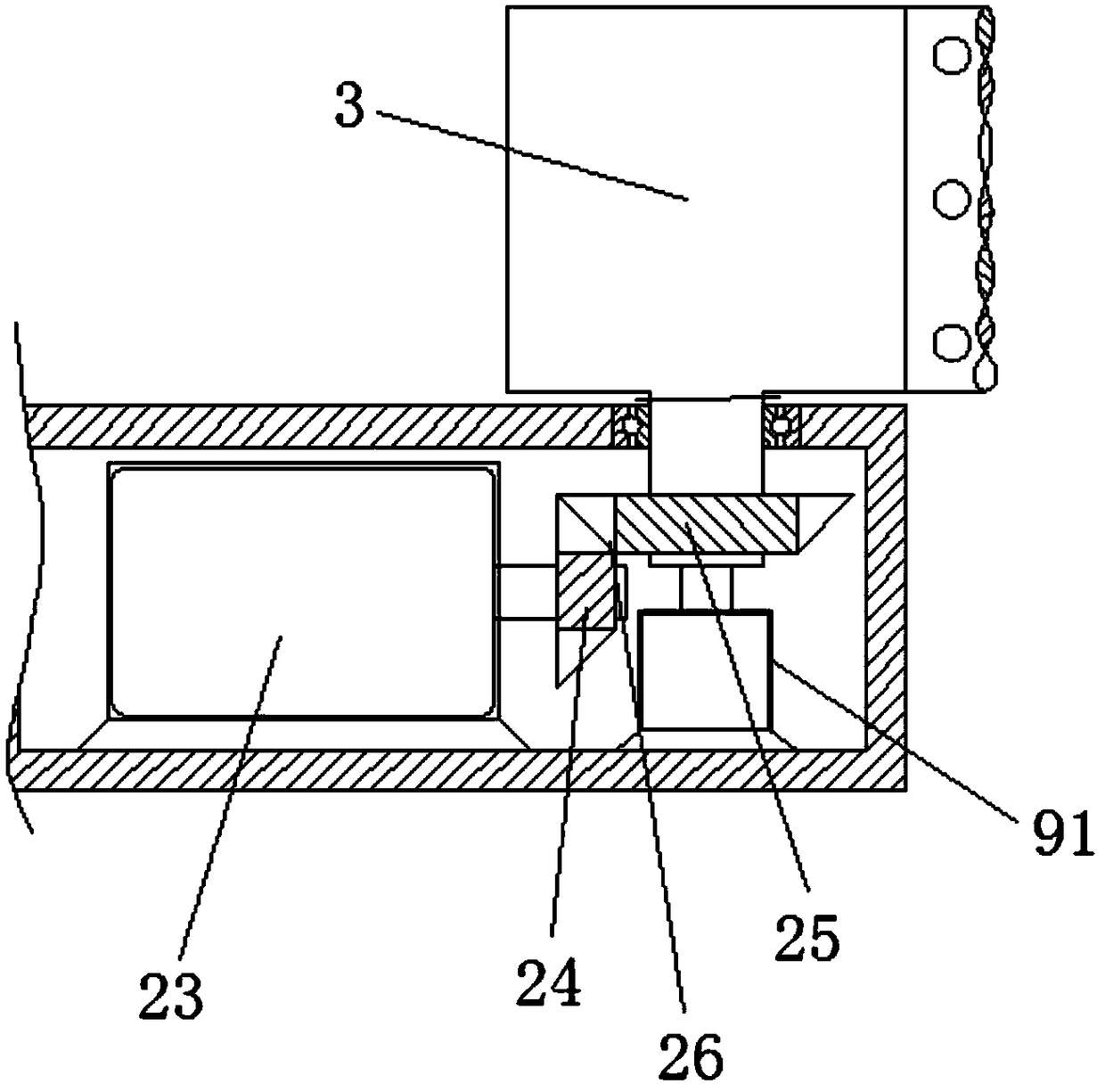

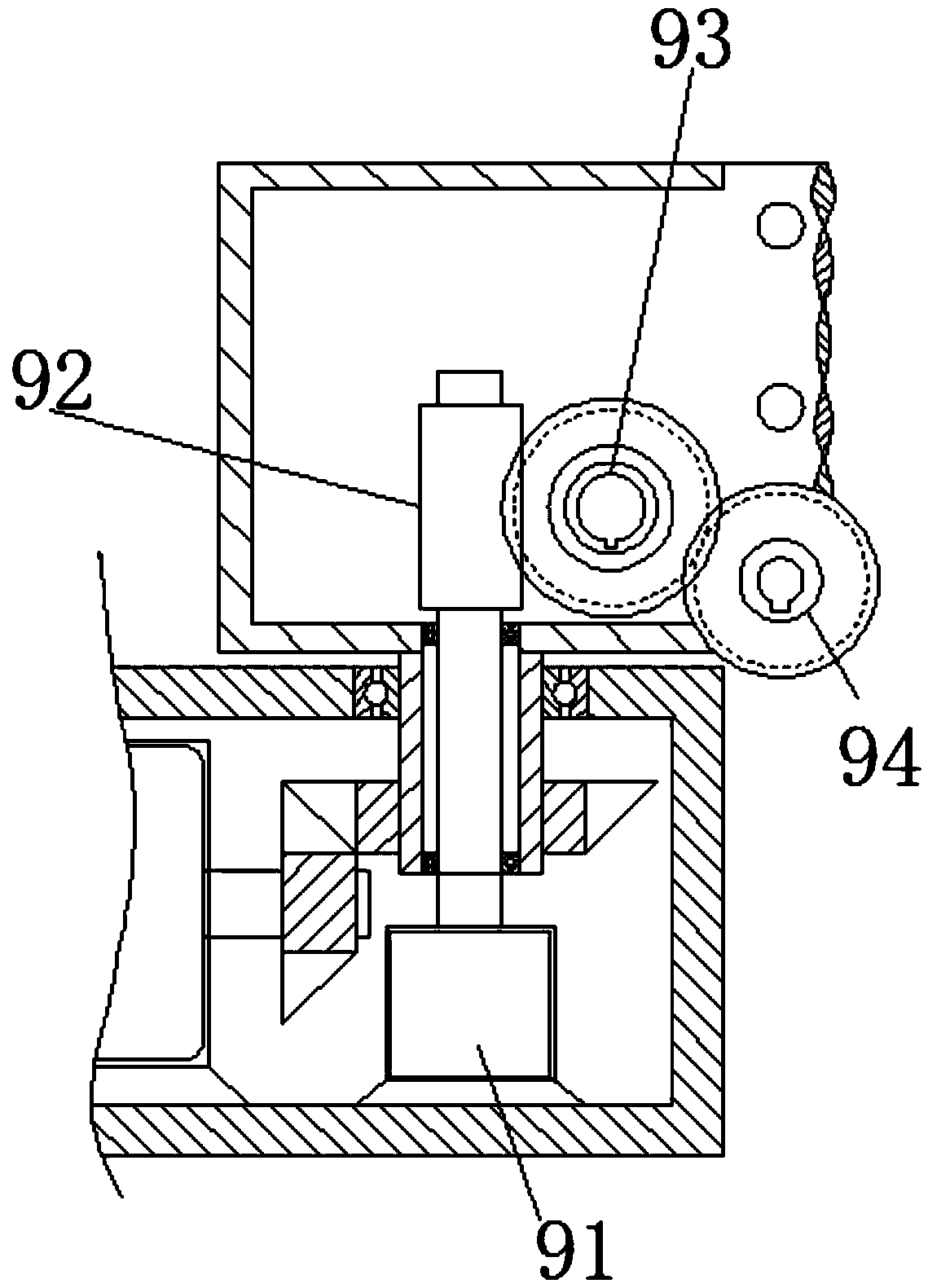

[0022] Such as Figure 1 to Figure 5 As shown, a tapping machine is characterized in that it includes a workbench 1, a hydraulic device 10, a main body 2, a rotating shaft 3, a connecting sleeve 31, a connecting block 32, a connecting rod mechanism 4, a rotating device 9, a servo motor 5, and a connecting body 51. Cooling device 6 and tapping mechanism 7. The hydraulic device 10 is provided in the inner cavity on the left side of the workbench 1. The hydraulic device 10 includes a hydraulic cylinder 11, a piston rod 12, a chute 13 and a main body mounting plate 14 , the hydraulic cylinder 11 is connected with the piston rod 12, the piston rod 12 is connected with the main body installation plate 14, the main body installation plate 14 is slidably matched with the chute, and the main body installation plate 14 is installed There is the main body 2; the inner cavity of the main body 2 is provided with the motor 23 and the gear transmission mechanism 26 electrically connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com