Land abalone culturing feeding system

A feeding system and abalone technology are applied in the field of feeding systems for feeding feed in a breeding box, which can solve the problems such as errors in hand measurement, death, and influence on the growth of abalone, and achieve fast unpacking, accurate measurement and convenient overall effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present application will be further described in detail through the following embodiments in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application.

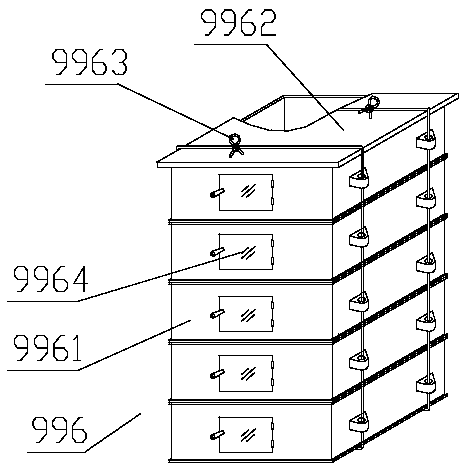

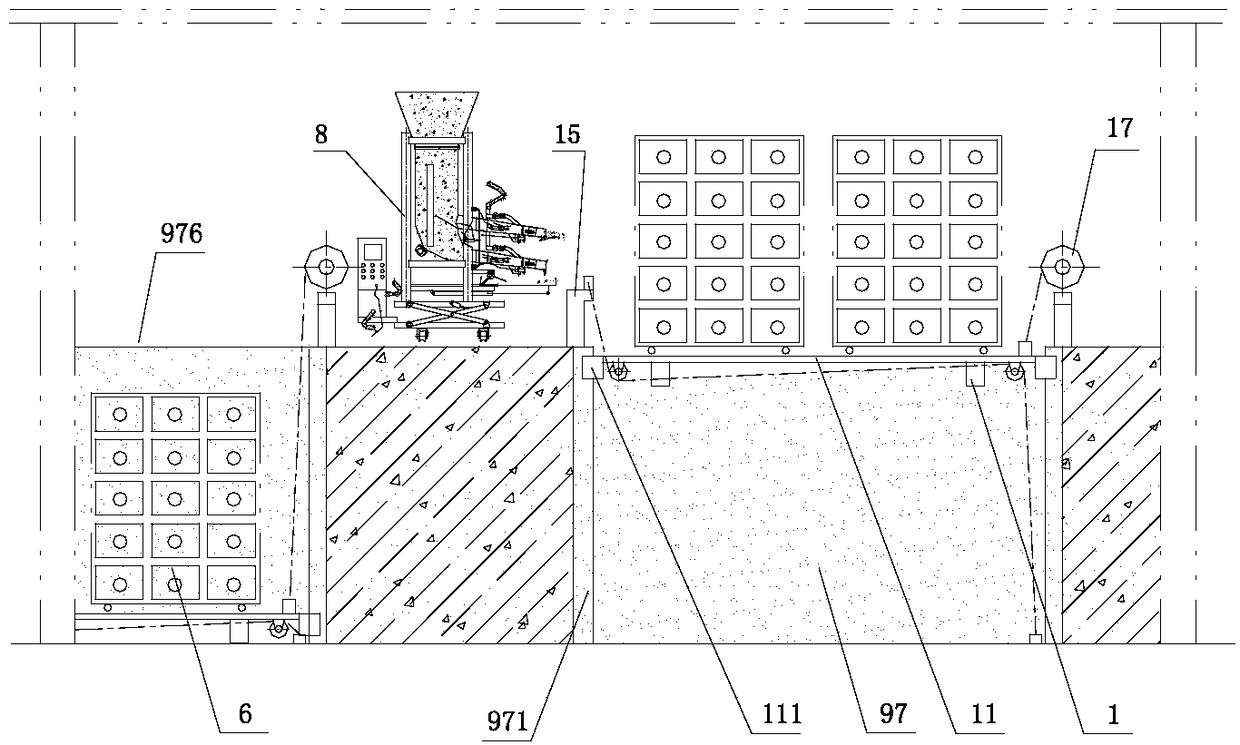

[0023] Such as image 3 , Figure 4 , Figure 5As shown, it is the front view, side view, and top view of a kind of shore abalone breeding feeding system described in the first embodiment of the present application. The feeding system includes a breeding pond 97, a breeding cabinet 6, an elevator 1, or another Feeding machine 8; each of the culture ponds 97 is provided under the floor of the workshop, and the vertical direction of the wall of the culture pond is provided with one or more strip-shaped guide rails 971, and the guide rails are groove-shaped strip-shaped depressions In the pool wall of the culture pond, water supply and drainage pipes and oxygen supply pipes are provided at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com