Multifunctional cable towing vehicle

A multi-functional, cable technology, used in cable laying equipment, motor vehicles, transportation and packaging, etc., can solve the problems of heavy cable weight, waste, and the inability of cable conveyors to adapt, and achieve the effect of large support area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the present invention better, below in conjunction with appendix Figure 1-10 Embodiments of the present invention will be explained in detail.

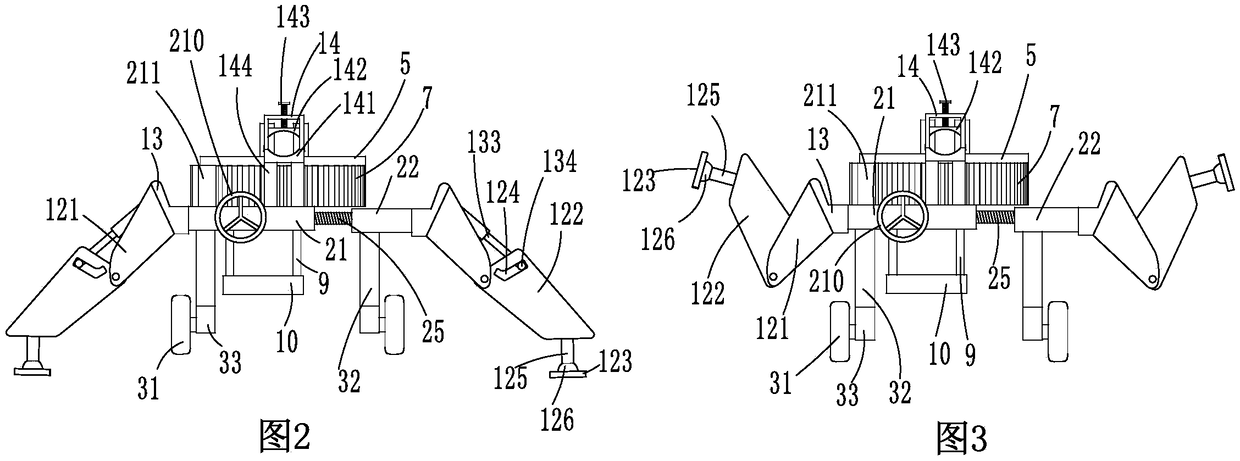

[0037] like Figure 1-Figure 3 As shown, the present invention includes a support device 1, a telescopic frame 2, a running device 3 and a clamp 14, and the telescopic frame 2 includes a fixed plate 21 and a movable plate 22, and between the fixed plate 21 and the movable plate 22 The distance between the fixed plate 21 and the movable plate 22 can be freely adjusted according to the width of the ravine when the cable is pulled across the ravine through the connection of the telescopic device.

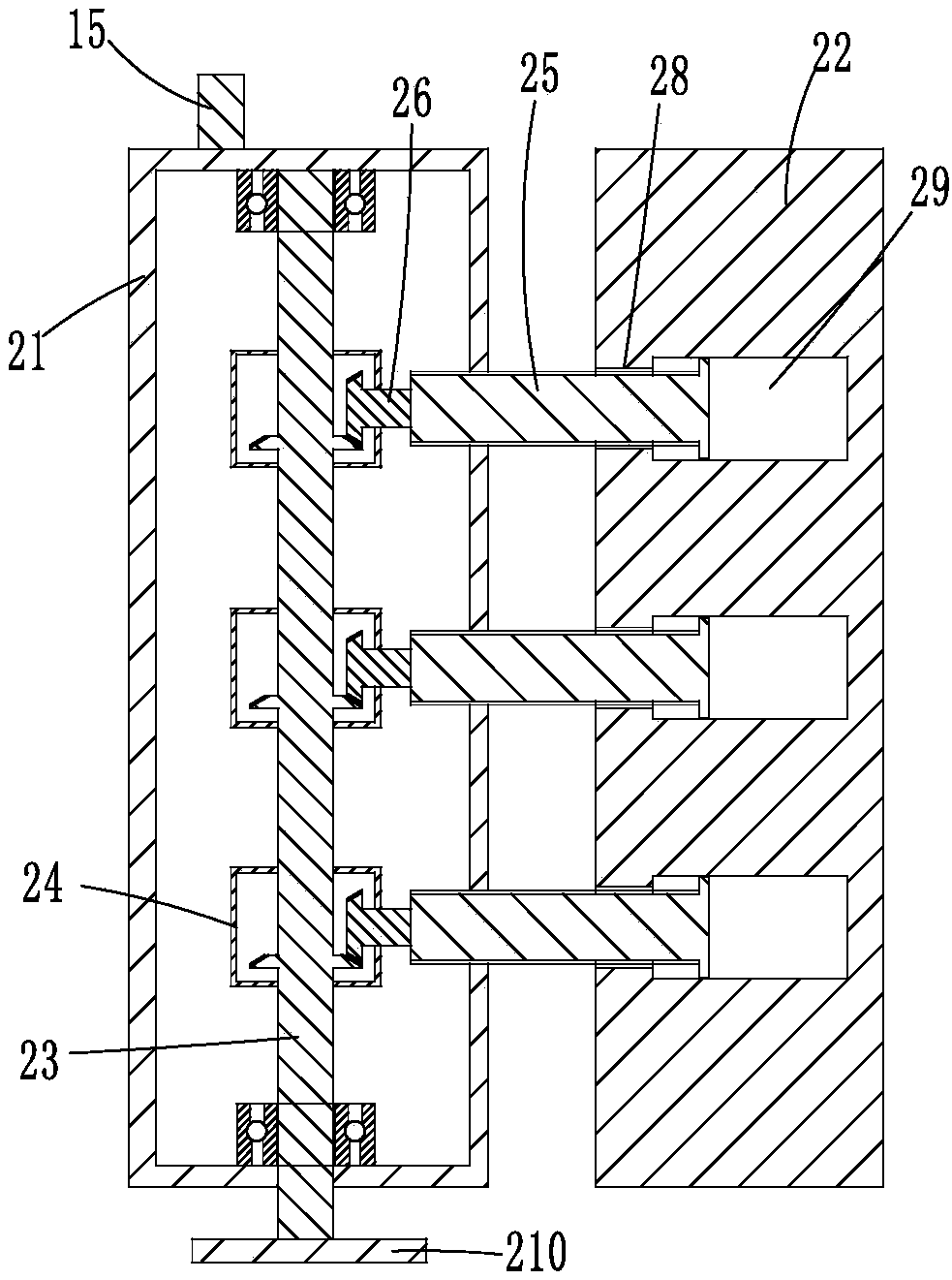

[0038] like Figure 1-Figure 4As shown, the telescopic device includes a driving shaft 23, several commutators 24 and several threaded rods 25, and more optimally, the number of the commutators 24 and the threaded rods 25 selected by the present invention is three , the fixed plate 21 is provided with the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com