An acoustic barrier for noise reduction in an outdoor substation

A technology for sound barriers and substations, applied in power distribution substations, anti-seismic equipment, etc., can solve the problems of poor weather resistance of sound barrier materials, decline in the overall performance of sound barriers, and increased noise energy loss, etc., to achieve good weather resistance and easy promotion and use , the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

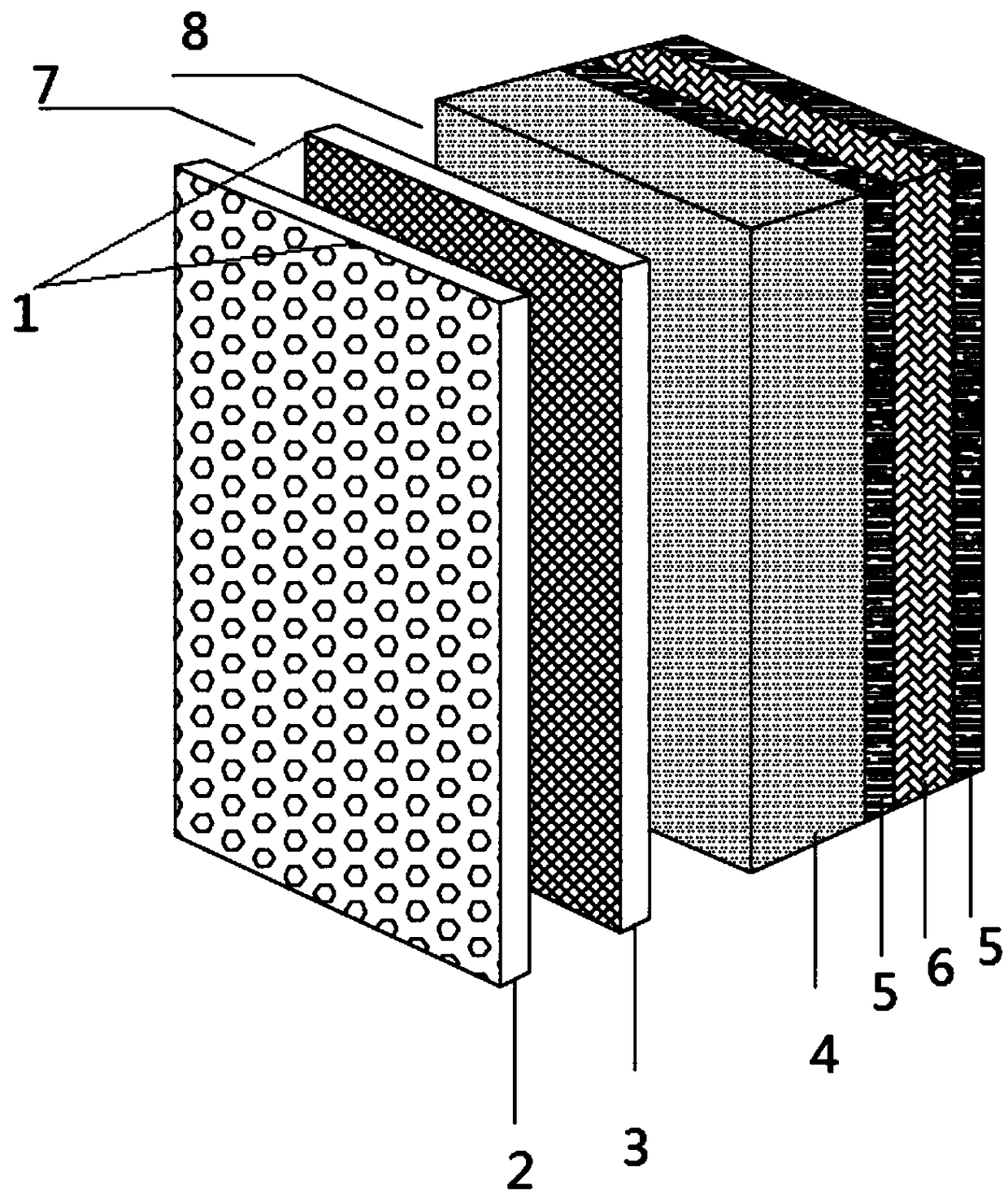

[0033] like figure 1 As shown, a sound barrier for outdoor substation noise reduction, the thickness of the sound barrier is 100mm; the sound barrier includes a microporous fiber composite sound-absorbing board 1, a rock wool board 4, a constrained damping board and a cavity, the The microporous fiber composite sound-absorbing board 1, the rock wool board 4 and the constrained damping board are placed in sequence in the horizontal direction, and the constrained damping board is located on the outermost side of the sound barrier; the microporous fiber composite sound-absorbing board 1 includes the inner layer The micro-perforated plate 2 and the outer aluminum fiber plate 3; a first cavity 7 is provided between the micro-perforated plate 2 and the aluminum fiber plate 3, and a second cavity 8 is provided between the aluminum fiber plate 3 and the rock wool plate 4;

[0034] The horizontal thickness of the first cavity 7 between the micro-perforated plate 2 and the aluminum fibe...

Embodiment 2

[0044] A sound barrier for outdoor substation noise reduction, the thickness of the sound barrier is 128mm; the sound barrier includes a microporous fiber composite sound-absorbing board, a rock wool board, a constrained damping plate and a cavity, and the microporous fiber composite sound-absorbing The sound board, the rock wool board and the constrained damping board are placed in sequence, and the constrained damping board is located on the outermost side of the sound barrier; the microporous fiber composite sound-absorbing board includes micro-perforated boards and aluminum fiber boards from the inside to the outside, and the micro-perforated There is a first cavity between the aluminum fiber board and the aluminum fiber board, and a second cavity between the aluminum fiber board and the rock wool board;

[0045] The distance in the horizontal direction of the first cavity between the micro-perforated plate and the aluminum fiber plate is 40mm;

[0046] The plate thickness...

Embodiment 3

[0053]A sound barrier for noise reduction in an outdoor substation, the thickness of the sound barrier is 150mm; the sound barrier comprises a microporous fiber composite sound-absorbing board, a rock wool board, a restraint damping board and a cavity, and the The sound board, the rock wool board and the constrained damping board are placed in sequence, and the constrained damping board is located at the outermost side of the sound barrier; the microporous fiber composite sound-absorbing board includes a micro-perforated board and an aluminum fiber board from the inside to the outside. A first cavity is provided between the board and the aluminum fiber board, and a second cavity is provided between the aluminum fiber board and the rock wool board;

[0054] The spacing in the horizontal direction of the first cavity between the micro-perforated board and the aluminum fiber board is 35 mm;

[0055] The thickness of the micro-perforated plate is 1 mm, the aperture is 1.5 mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com